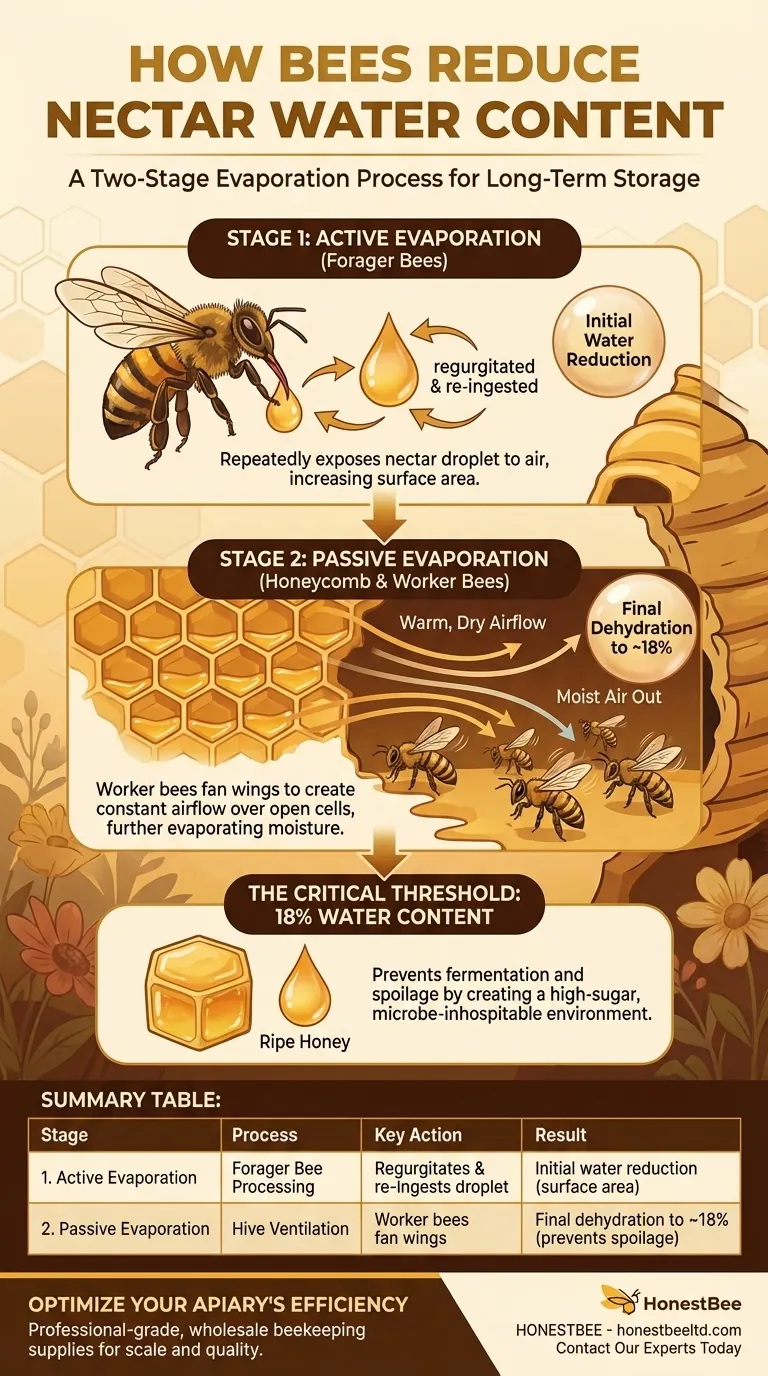

To reduce the water content in nectar, bees employ a two-stage evaporation process. First, a forager bee repeatedly regurgitates and re-ingests a nectar droplet to expose it to the air. Second, once deposited in the honeycomb, worker bees collectively fan their wings at the hive entrance to create a warm, dry airflow that further evaporates moisture from the nectar until it becomes honey.

The core challenge for bees is converting perishable nectar into a stable, long-term food source. The entire process is a sophisticated system designed to remove excess water, which prevents fermentation and spoilage.

The Journey from Nectar to Honey

The transformation of nectar into honey is a critical survival mechanism for the bee colony. Raw nectar, with a water content often exceeding 80%, is highly susceptible to spoilage from naturally occurring yeasts and bacteria.

Stage 1: Active Evaporation by Forager Bees

When a forager bee returns to the hive, it doesn't immediately deposit the collected nectar. Instead, it begins the initial phase of dehydration.

The bee regurgitates a small droplet of nectar onto the tip of its proboscis (tongue), exposing the liquid to the warmer air of the hive.

It then draws the droplet back in and repeats this "bubbling" or "tongue-lashing" process for up to 20 minutes. This action dramatically increases the nectar's surface area, accelerating initial water evaporation.

Stage 2: Passive Evaporation in the Honeycomb

After this initial dehydration, the nectar is deposited into an open cell within the honeycomb. At this point, the colony's "house bees" take over.

The nectar is intentionally spread thinly across the surface of the wax cells to maximize its exposure to air.

Worker bees then congregate near the hive entrance and vigorously fan their wings. This collective effort creates a continuous, controlled airflow throughout the hive.

This fanning acts like a ventilation system, pushing warm, moist air out and drawing cooler, drier air in. The constant circulation over the open honeycomb cells steadily carries moisture away from the ripening nectar.

The Critical Threshold: Why 18% Water Content Matters

The entire process continues until the nectar's water content is reduced from its initial 60-80% down to approximately 17-18%.

Preventing Fermentation

This low water level creates a high-sugar concentration that is inhospitable to microbes. The osmotic pressure is so intense that it draws water out of any yeast or bacterial cells, effectively killing them and preventing fermentation.

Ensuring Long-Term Storage

By achieving this stable state, the bees create honey—a food source that can be stored indefinitely. This allows the colony to survive winters and periods when nectar is scarce.

Once the honey is "ripe" (at the correct water content), the bees cap the honeycomb cell with a beeswax seal, preserving it for future use.

Making the Right Choice for Preservation

The bees' methods are a masterclass in food preservation, directly applicable to human techniques. Understanding their goal helps explain their process.

- If the primary focus is rapid dehydration: The active "bubbling" by a single bee, which maximizes surface area, is the most efficient initial step.

- If the primary focus is long-term stability: The slow, controlled airflow over a large surface area is essential to reach the critical sub-18% water content needed to prevent spoilage.

Ultimately, the bees' two-stage system ensures both speed and final quality, turning a fleeting resource into a permanent food supply.

Summary Table:

| Stage | Process | Key Action | Result |

|---|---|---|---|

| 1. Active Evaporation | Forager Bee Processing | Regurgitates and re-ingests nectar droplet | Initial water reduction via increased surface area |

| 2. Passive Evaporation | Hive Ventilation | Worker bees fan wings to create airflow | Final dehydration to ~18% water content, preventing spoilage |

Optimize Your Apiary's Efficiency with Professional-Grade Equipment

Just as bees masterfully preserve their food supply, commercial apiaries and distributors need reliable tools to ensure productivity and honey quality. HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment designed for scale and efficiency.

Contact our experts today to discuss how our solutions can help you streamline your operations and improve your yield.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Can you dehumidify honey? A Beekeeper's Guide to Preventing Fermentation

- How does temperature regulation help in managing honey moisture content? Prevent Fermentation & Ensure Quality

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- What are some tips for preventing excess moisture in honey during harvesting? Essential Steps for a Stable Harvest

- What are the advantages of a condensation honey dryer? Boost Quality & Yield for Your Apiary