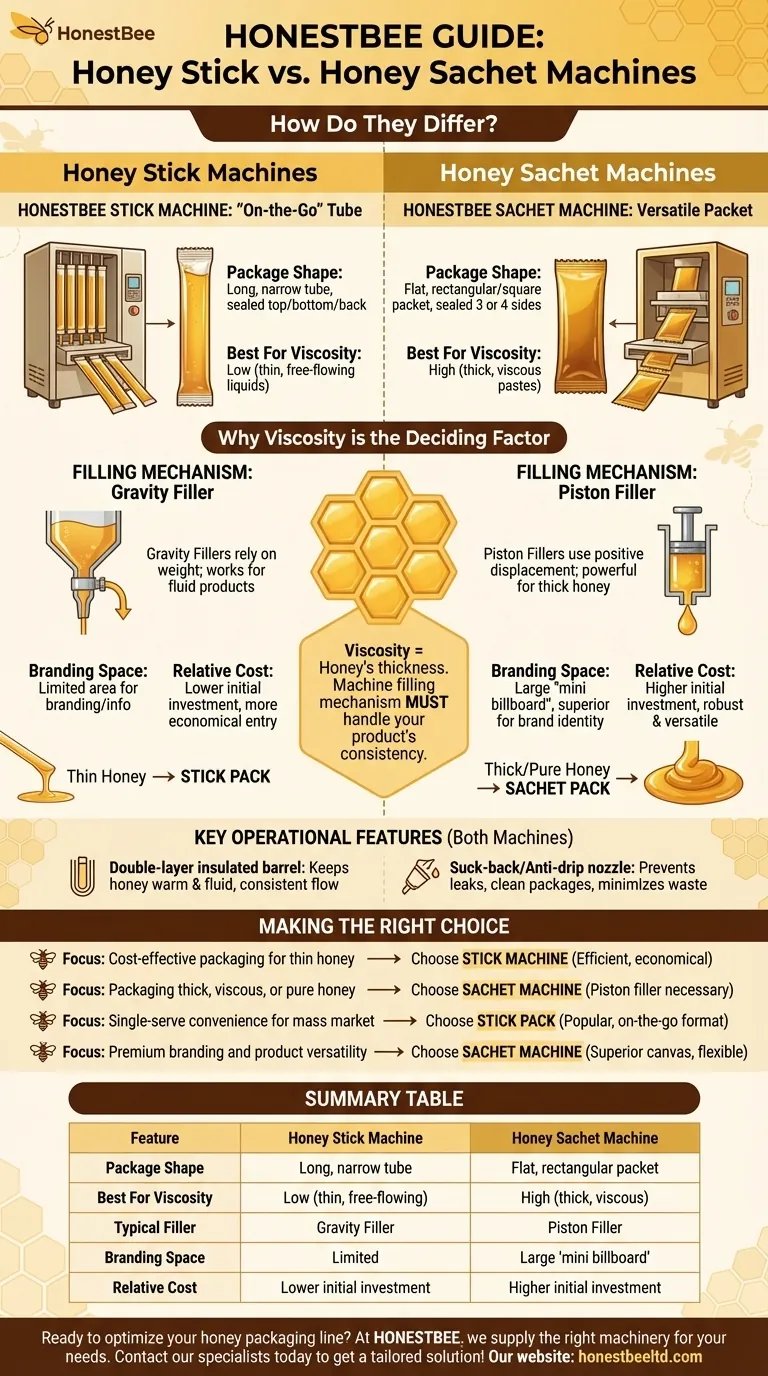

At their core, honey stick and honey sachet machines produce different package formats tailored to different product types. A honey stick machine creates long, narrow tubes best suited for thin, free-flowing liquids. In contrast, a honey sachet machine produces flat, rectangular packets that are more versatile and capable of handling thicker, more viscous honey.

The choice between a stick and a sachet machine is not merely about the final package shape. It is a strategic decision dictated by your honey's viscosity, your budget, and your branding goals.

The Core Distinction: Shape and Sealing

The most visible difference between these machines lies in the packaging they create. This fundamental difference in form directly influences their function and ideal use case.

Honey Stick Machines: The "On-the-Go" Tube

Honey stick machines create a long, tube-like package known as a stick pack. These are formed by sealing the film at the top, bottom, and down the back.

This format has a high length-to-width ratio. It is primarily designed for low-viscosity or "free-flowing" products that can easily fill the narrow tube.

Honey Sachet Machines: The Versatile Packet

Honey sachet machines produce flat, rectangular, or square packets known as sachets. These are typically sealed on three or four sides.

This wider, flatter format provides a larger surface area for branding. Crucially, it is suitable for a wide range of materials, including the thick, viscous pastes characteristic of many pure honey products.

Why Viscosity is the Deciding Factor

Honey's thickness, or viscosity, is the single most important technical factor when choosing a packaging machine. The machine's filling mechanism must be able to handle your specific product consistently and accurately.

The Role of the Filling Mechanism

How the machine dispenses honey into the package is critical. The two common technologies are piston fillers and gravity fillers, and they are not interchangeable.

Piston Fillers for Thick Honey

Piston fillers use a cylinder to pull in and then push out a precise, pre-set volume of product. This positive displacement action is powerful enough to move thick, slow-moving liquids like honey.

These systems are known for their high accuracy and are essential for packaging viscous honey without causing blockages or inaccurate fills. They are more commonly found on sachet machines designed for greater product versatility.

Gravity Fillers for Thin Liquids

Gravity fillers rely on the weight of the liquid to fill the package from a hopper located above the filling nozzle. This method works well for thin, water-like liquids.

While simple and cost-effective, a gravity filler will struggle to handle thick honey, leading to slow production speeds and inconsistent package weights. They are often paired with stick pack machines intended for more fluid products.

Understanding the Trade-offs: Cost vs. Capability

Your decision also involves balancing initial investment against long-term operational needs and branding opportunities.

Initial Investment

As a general rule, honey sachet machines are more expensive. Their robust construction and advanced specifications, such as the inclusion of a powerful piston filler, contribute to a higher upfront cost.

Honey stick machines are often a more economical entry point, especially for producers focusing on a single, low-viscosity product.

Key Operational Features

Regardless of machine type, certain features are vital for efficiently packaging honey. Look for a double-layer insulated barrel to keep the honey warm and fluid, ensuring a consistent flow.

Additionally, a suck-back or anti-drip nozzle is critical. This feature prevents honey from leaking or stringing after a fill, keeping packages clean and minimizing product waste.

Branding and Material Usage

Stick packs use less packaging film per unit, which can reduce material costs. However, their narrow shape offers limited space for branding and nutritional information.

Sachets provide a much larger surface area, acting as a "mini billboard" for your brand. This is a significant advantage for products competing on a crowded shelf.

Making the Right Choice for Your Honey Product

To select the correct machine, analyze your product's properties against your business goals.

- If your primary focus is cost-effective packaging for thin, fluid honey: A honey stick machine is your most efficient and economical choice.

- If your primary focus is packaging thick, viscous, or pure honey: A sachet machine equipped with a piston filler is necessary to handle the product correctly.

- If your primary focus is single-serve convenience for a mass market: The stick pack is a highly popular and recognizable format for on-the-go consumption.

- If your primary focus is premium branding and product versatility: A sachet machine offers a superior canvas for your brand identity and the flexibility to package other products in the future.

By aligning your machine choice with your product's specific properties and your brand's market goals, you invest not just in packaging, but in a successful and efficient operation.

Summary Table:

| Feature | Honey Stick Machine | Honey Sachet Machine |

|---|---|---|

| Package Shape | Long, narrow tube | Flat, rectangular packet |

| Best For Viscosity | Low (thin, free-flowing) | High (thick, viscous) |

| Typical Filler | Gravity Filler | Piston Filler |

| Branding Space | Limited | Large 'mini billboard' |

| Relative Cost | Lower initial investment | Higher initial investment |

Ready to optimize your honey packaging line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the right machinery to match their specific product and business goals. Whether you need a cost-effective stick pack machine for fluid honey or a robust sachet machine with a piston filler for pure, viscous honey, our expertise ensures you invest in efficiency and success.

Contact our packaging specialists today to discuss your needs and get a tailored solution!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

People Also Ask

- What advantages do high-precision honey filling machines provide? Optimize Yield and Preserve Botanical Quality

- What are the technical advantages of using an automatic filling machine? High-Precision Honey Packaging Solutions

- What is the importance of using high-precision filling machines in honey bottling? Secure Purity & Profits

- What are the primary advantages of automated honey-filling machinery? Boost Efficiency and Ensure Product Purity

- What factors should be considered when choosing a honey filling machine? Optimize Your Production Line

- What role do industrial-grade honey filling machines play? Scale Your Apiary Production with Precision and Speed

- What are the different types of honey filling machines? Choose the Right Equipment for Your Apiary

- Why are automated honey-filling machines critical for commercial efficiency? Maximize Yield & Export Compliance