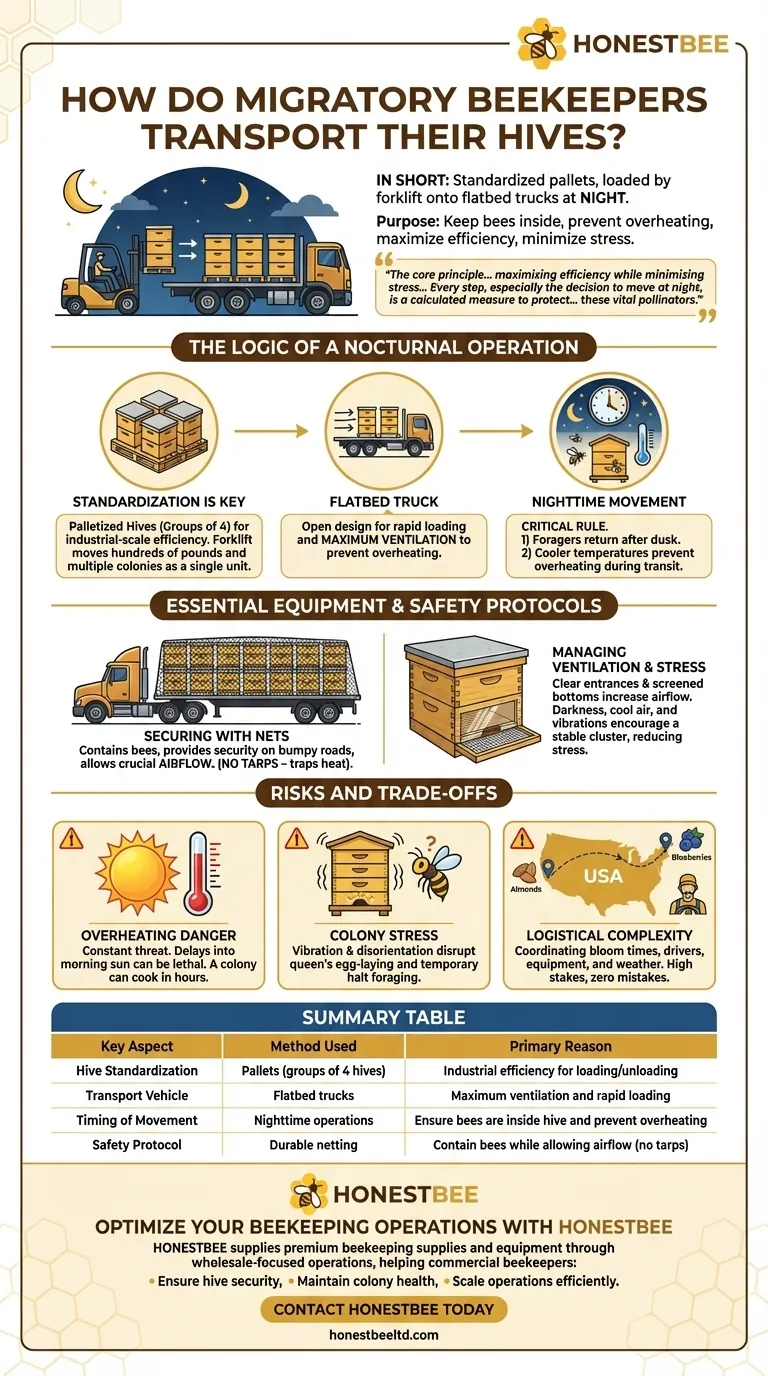

In short, migratory beekeepers transport hives using a standardized system of palletized hives, loaded by forklift onto flatbed trucks. The entire operation is strategically conducted at night to ensure the bees are inside the hive and to prevent the colony from overheating during transit.

The core principle behind large-scale hive transportation is maximizing efficiency while minimizing stress and loss to the bee colonies. Every step, especially the decision to move at night, is a calculated measure to protect the health and integrity of these vital pollinators.

The Logic of a Nocturnal Operation

The entire process of moving thousands of beehives is a carefully choreographed logistical feat. The fundamental choices—pallets, flatbeds, and night travel—are driven by the biology of the bees and the economics of modern agriculture.

Why Standardization is Key

Hives are almost universally kept on wooden pallets, typically in groups of four. This isn't for convenience; it's for industrial-scale efficiency.

This standardization allows a forklift or similar heavy equipment to lift and move hundreds of pounds and four distinct colonies as a single unit. It's the only feasible way to load and unload the thousands of hives required for large-scale pollination contracts.

The Role of the Flatbed Truck

Flatbed trucks are the vehicle of choice for migratory beekeepers. Their open design allows for rapid loading and unloading of pallets from the side.

Most importantly, the open-air nature of a flatbed provides maximum ventilation. Bee colonies generate a tremendous amount of heat, and good airflow is critical to prevent them from overheating during the journey.

Why All Movement Happens at Night

Transporting bees at night is the most critical rule of the operation. This is done for two primary reasons.

First, bees are foragers that work during daylight hours. By moving after dusk, beekeepers ensure that the vast majority of the colony's foraging bees have returned to the hive. Moving during the day would mean leaving a significant portion of the workforce behind.

Second, cooler nighttime temperatures help prevent the colonies from overheating. The stress and vibration of travel cause the bees to become highly active, generating even more heat than usual. Attempting a move in the heat of the day would risk killing the entire colony.

Essential Equipment and Safety Protocols

Beyond the basic method, specific equipment is used to ensure the safety of the bees and the public. Protecting the colony from stress is paramount.

Securing the Load with Nets

Once loaded, the pallets of hives are covered with large, durable netting. This net serves multiple purposes.

It acts as a final barrier to keep bees contained if they emerge from the hive entrances during transit. It also provides an extra layer of security, helping to hold the hives and their components together over bumpy roads while still allowing for crucial airflow. Using a tarp is not an option, as it would trap heat and suffocate the colonies.

Managing Ventilation and Stress

Overheating is the single greatest risk during a move. Beekeepers ensure entrances are clear and may use screened bottom boards to increase airflow from below.

The goal is to keep the bees clustered and calm. The darkness, cool air, and vibrations of the truck often encourage the bees to form a stable cluster, reducing stress and heat generation until they arrive at their new location.

Understanding the Risks and Trade-offs

While the process is highly refined, it is not without significant risks and challenges that beekeepers must constantly manage.

The Danger of Overheating

Even with night travel and netting, overheating remains a constant threat. A delay that pushes the journey into the morning sun, a truck breakdown, or a traffic jam can quickly become a lethal event for the bees. A colony can literally cook itself in a matter of hours.

Stress on the Colony

Moving is inherently stressful for a bee colony. The vibration and disorientation can disrupt the queen's egg-laying and temporarily halt foraging. It can take a few days for the bees to reorient themselves to their new location and return to peak productivity.

Logistical Complexity

A migratory beekeeping operation is a marvel of logistics. It requires coordinating bloom times for various crops—from almonds in California to blueberries in Maine—with truck drivers, equipment, and weather forecasts. The financial stakes are high, and a single mistake can have cascading consequences.

Applying This Understanding

Grasping the logistics of migratory beekeeping provides insight into a critical component of our food system. The principles apply whether you are a hobbyist or an agricultural professional.

- If your primary focus is hobby beekeeping: The core principle remains the same for moving a single hive. Always transport your bees at night or in very cool weather to keep the full colony together and prevent overheating.

- If you are involved in agriculture: Understand that beekeepers operate on a tight, high-stakes schedule. Clear communication regarding bloom times and pesticide applications is essential for a successful pollination partnership.

- If you are simply curious about our food system: Recognize that the movement of these hives is a foundational, yet often invisible, service that makes the production of roughly one-third of the food we eat possible.

Ultimately, the transportation of beehives is a perfect example of human ingenuity working in alignment with the fundamental biology of a vital insect.

Summary Table:

| Key Aspect | Method Used | Primary Reason |

|---|---|---|

| Hive Standardization | Pallets (groups of 4 hives) | Industrial efficiency for loading/unloading |

| Transport Vehicle | Flatbed trucks | Maximum ventilation and rapid loading |

| Timing of Movement | Nighttime operations | Ensure bees are inside hive and prevent overheating |

| Safety Protocol | Durable netting | Contain bees while allowing airflow (no tarps) |

Optimize Your Beekeeping Operations with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, you understand the critical importance of reliable equipment and efficient hive management. The challenges of migratory beekeeping—from preventing colony stress during transport to maintaining hive health—require specialized solutions.

HONESTBEE supplies premium beekeeping supplies and equipment through wholesale-focused operations, helping commercial beekeepers:

- Ensure hive security with durable pallets and transport-ready equipment

- Maintain colony health with proper ventilation systems and stress-reduction tools

- Scale operations efficiently with standardized equipment designed for large-scale movement

Our products are specifically engineered for the demands of migratory beekeeping, helping you protect your valuable colonies during transport and maximize pollination success.

Ready to enhance your hive transportation system? Contact HONESTBEE today to discuss wholesale pricing and equipment solutions tailored to your commercial beekeeping needs.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Professional Grade Foldable Beehive Handles

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

People Also Ask

- What is the significance of professional hive-making tools? Scale Your Stingless Bee Farm with Precision Equipment

- What are the basic tools for beekeeping? Essential Starter Kit for Safe & Successful Hive Management

- How does the hive splitting process contribute to colony management? Master Your Apiary Recovery Strategies

- Why is it important to compare the progress of different hives? A Beekeeper's Key Diagnostic Tool

- What is the hole in a hive tool for? A Multi-Tool for Apiary Repairs and Maintenance