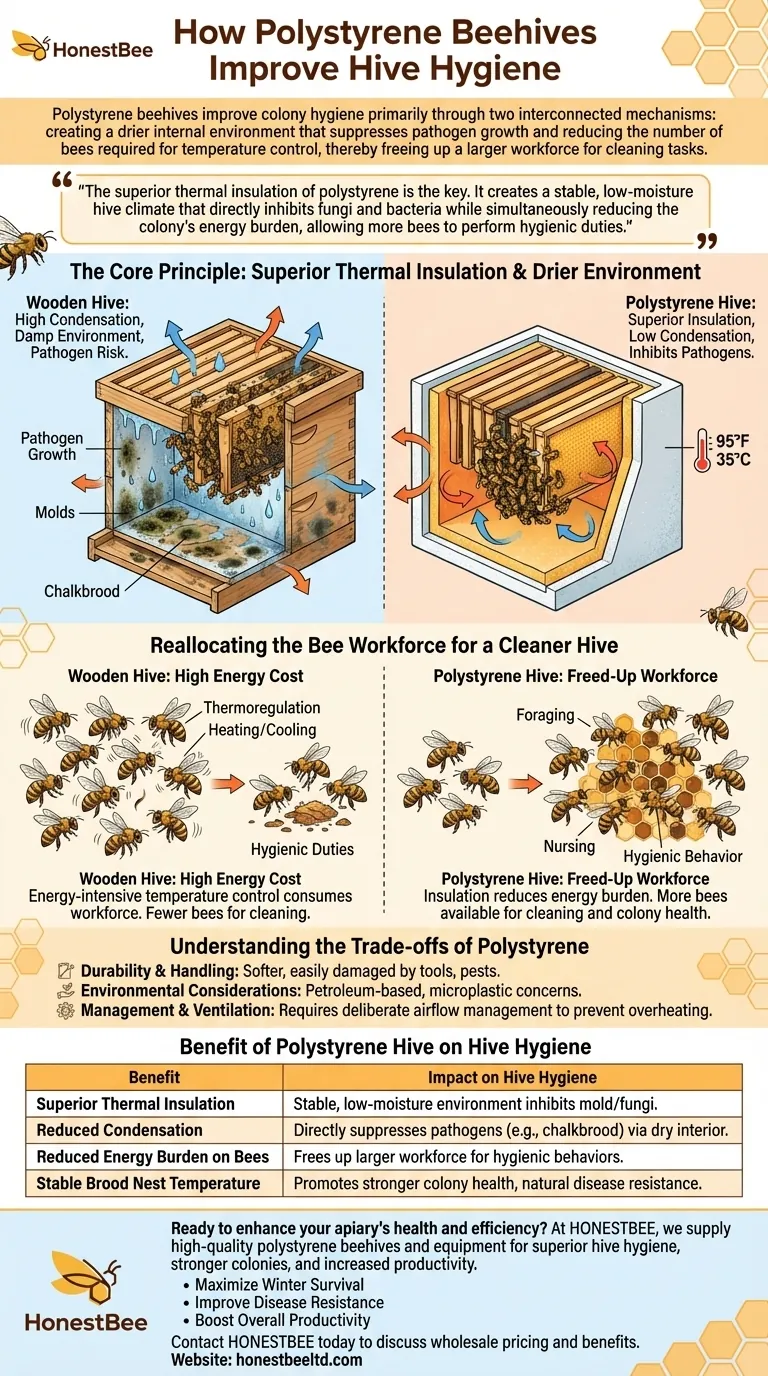

Polystyrene beehives improve colony hygiene primarily through two interconnected mechanisms: creating a drier internal environment that suppresses pathogen growth and reducing the number of bees required for temperature control, thereby freeing up a larger workforce for cleaning tasks.

The superior thermal insulation of polystyrene is the key. It creates a stable, low-moisture hive climate that directly inhibits fungi and bacteria while simultaneously reducing the colony's energy burden, allowing more bees to perform hygienic duties.

The Core Principle: Superior Thermal Insulation

A hive's material directly influences its internal environment. The properties of expanded polystyrene (EPS) create a cascade of benefits for bee health, all stemming from its ability to insulate.

How Insulation Stabilizes the Hive Climate

Polystyrene is a significantly better insulator than wood. This means it shields the colony from extreme external temperatures, keeping the brood nest warmer in the winter and cooler in the summer.

This stability drastically reduces the energy the colony must expend to maintain the critical brood nest temperature of approximately 95°F (35°C).

Reducing Condensation and Moisture

In a traditional timber hive, the warm, moist air generated by the bee cluster often condenses on the cold inner walls, especially during cool nights or winter. This creates a damp environment.

Because polystyrene hive walls stay closer to the internal hive temperature, this condensation is significantly reduced. The result is a much drier hive interior.

The Impact on Pathogen Growth

A dry environment is inhospitable to many common bee pathogens. Harmful molds, fungi (like Ascosphaera apis, which causes chalkbrood), and certain bacteria thrive in the damp conditions often found in wooden hives.

By preventing moisture buildup, polystyrene hives create an environment that naturally suppresses the development of these diseases, contributing directly to better colony health and hygiene.

Reallocating the Bee Workforce for a Cleaner Hive

A bee colony allocates its workforce based on immediate needs. A polystyrene hive fundamentally changes the colony's primary "needs list" by taking over a critical, energy-intensive job.

The Energy Cost of Thermoregulation

In a wooden hive, a large contingent of bees must dedicate themselves to thermoregulation. In winter, they form a tight cluster and vibrate their wing muscles to generate heat. In summer, they fan their wings and perform evaporative cooling to prevent overheating.

This is a constant, demanding task that consumes a significant portion of the colony's workforce and food reserves.

Freeing Up the Workforce

Because insulation does most of the work of maintaining a stable temperature, the bees previously assigned to "heating" or "cooling" duties are freed up for other tasks.

This change in labor allocation means a larger percentage of the hive's population can engage in foraging, nursing, and, crucially, hygienic behaviors.

The Direct Link to Improved Hygiene

Hygienic behavior is a key indicator of colony health. It includes tasks like quickly removing dead or diseased brood, clearing out dead adult bees, and removing debris from the hive floor.

With a larger workforce available for these duties, the hive is kept cleaner, further reducing disease transmission and contributing to the overall vigor of the colony.

Understanding the Trade-offs of Polystyrene

While beneficial for hygiene and thermal management, polystyrene hives are not without their drawbacks. An objective assessment requires acknowledging their limitations compared to traditional timber.

Durability and Handling

Polystyrene is softer than wood and can be easily damaged by hive tools during inspections. It is also more susceptible to damage from pests like wax moths and rodents if the hive exterior is compromised.

Environmental Considerations

Timber is a natural, renewable, and biodegradable material. Polystyrene is a petroleum-based plastic, which raises valid concerns about its long-term environmental impact and microplastic pollution.

Management and Ventilation

While polystyrene provides excellent insulation, it can lead to overheating in very hot climates if not managed with proper ventilation. Unlike wood, which can "breathe" to some extent, a polystyrene hive is a sealed system requiring deliberate airflow management by the beekeeper.

Making the Right Choice for Your Goal

The decision between polystyrene and timber depends entirely on your beekeeping goals, climate, and management philosophy.

- If your primary focus is maximizing winter survival and spring buildup: Polystyrene's insulation provides a distinct advantage in temperate or cold climates, leading to stronger colonies earlier in the season.

- If your primary focus is minimizing disease through environmental control: The dry internal environment of a polystyrene hive directly inhibits common moisture-related pathogens like chalkbrood.

- If your primary focus is long-term durability and natural materials: A well-maintained timber hive is a time-tested, robust, and biodegradable option that can last for decades.

Ultimately, understanding how your choice of hive material affects the colony's energy budget is the key to promoting a healthy and productive hive.

Summary Table:

| Benefit of Polystyrene Hive | Impact on Hive Hygiene |

|---|---|

| Superior Thermal Insulation | Creates a stable, low-moisture environment that inhibits mold and fungi. |

| Reduced Condensation | Directly suppresses pathogens like chalkbrood by keeping the hive interior dry. |

| Reduced Energy Burden on Bees | Frees up a larger workforce to perform hygienic behaviors like removing dead brood. |

| Stable Brood Nest Temperature | Promotes stronger colony health and vigor, leading to better natural disease resistance. |

Ready to enhance your apiary's health and efficiency?

At HONESTBEE, we supply high-quality polystyrene beehives and beekeeping equipment to commercial apiaries and distributors. Our hives are designed to promote superior hive hygiene, leading to stronger colonies and increased productivity.

Let us help you achieve your goals:

- Maximize Winter Survival: Ensure your colonies emerge strong in the spring.

- Improve Disease Resistance: Create an environment that naturally suppresses common pathogens.

- Boost Overall Productivity: Healthier bees are more productive bees.

Contact HONESTBEE today to discuss wholesale pricing and how our equipment can benefit your operation.

Visual Guide

Related Products

- Professional Insulated Plastic Bee Hives

- Professional Insulated Winter Hive Wrap for Beekeeping

- Yellow Plastic Bucket Pail Perch for Beekeeping

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

People Also Ask

- Is polystyrene better than wood beehives? A Modern Choice for Healthier Bees & Easier Management

- How does the orientation of the hive sides benefit comb construction? Ensure Straight, Movable Combs for Easier Hive Management

- How much additional time does having more hives require? Master Efficient Apiary Management

- Are plastic beehives good? The Ultimate Guide to Durability and Low Maintenance

- Why is it recommended to buy at least two bee hives? Boost Your Success with a Second Colony