At its core, a piston filling machine operates on a simple, two-stroke mechanical principle. It uses a piston moving within a precisely machined cylinder to first draw in a specific volume of product from a hopper and then forcefully dispense that exact volume into a container through a nozzle. This mechanism is exceptionally effective for a wide range of product types, from thin liquids to thick creams and even products containing particulates.

A piston filler is a volumetric filling device, meaning it dispenses a consistent volume of product with each cycle. Its primary strengths are high accuracy and the power to handle viscous or chunky materials that other fillers cannot.

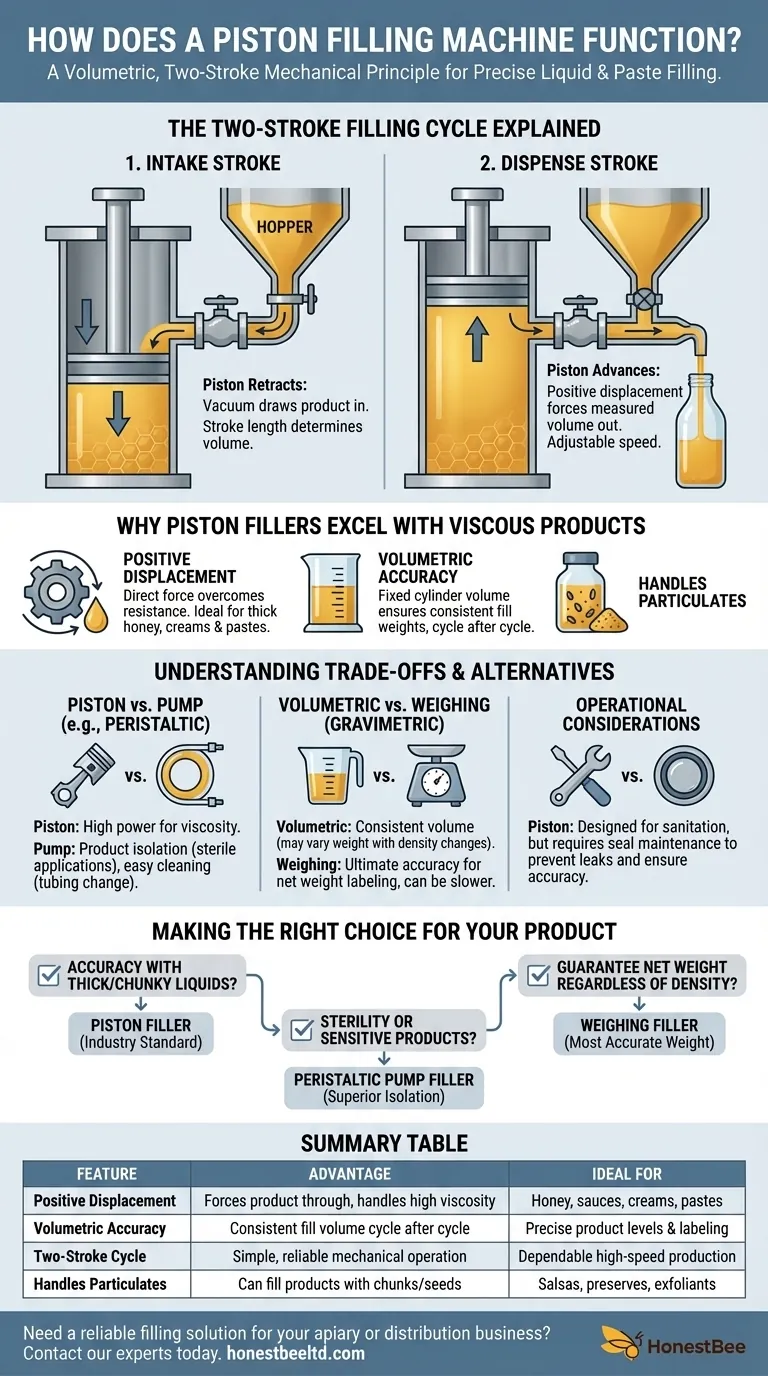

The Two-Stroke Filling Cycle Explained

The operation of a piston filler can be broken down into two distinct phases: the intake stroke and the dispense stroke. This cycle is what guarantees a precise and repeatable fill amount.

The Intake Stroke: Drawing in the Product

During the intake stroke, the piston retracts within the cylinder. This movement creates a vacuum, which pulls the product from a supply hopper through a valve and into the cylinder.

The volume of the cylinder determines the maximum amount of product that can be drawn in. The length of the piston's stroke can be adjusted to control the precise volume for each fill.

The Dispense Stroke: Ejecting the Product

Once the cylinder is filled, the valve system switches position. The intake path from the hopper closes, and the output path to the filling nozzle opens.

The piston then moves forward, pushing the measured volume of product out of the cylinder and through the nozzle into the waiting container. The speed of this stroke can often be adjusted to manage foaming or splashing.

Why Piston Fillers Excel with Viscous Products

The design of a piston filler is what makes it a go-to solution for challenging products like honey, sauces, creams, and pastes. This is due to two key principles.

Positive Displacement for Forceful Action

Piston fillers are a form of positive displacement machinery. Unlike systems that rely on gravity or centrifugal force, the piston physically forces the product through the system.

This direct force easily overcomes the resistance of thick, viscous liquids, ensuring a smooth and consistent flow where other fillers might struggle or fail completely.

Volumetric Accuracy for Consistency

Because the fill amount is determined by the fixed volume of the cylinder and the piston's travel distance, the machine delivers exceptional volumetric accuracy cycle after cycle.

As long as the product's density is consistent, this translates directly into highly consistent fill weights and professional-looking product levels in the final container.

Understanding the Trade-offs and Alternatives

While powerful, a piston filler is not the only solution. Understanding its limitations compared to other technologies is crucial for making an informed decision.

Piston vs. Pump Fillers

Pump fillers use mechanisms like gears, lobes, or peristaltic tubes to move product. A peristaltic pump filler is particularly useful as it never allows the product to touch the machine's mechanical components.

This makes peristaltic pumps ideal for sterile applications or when handling corrosive products, as only the inexpensive tubing needs to be replaced between batches, simplifying sanitation.

Piston (Volumetric) vs. Weighing (Gravimetric) Fillers

A piston filler works by volume. If your product's density changes with temperature (like honey) or from batch to batch, a consistent volume may not result in a consistent weight.

A weighing filler (or gravimetric filler) dispenses product until the container reaches a target weight. This method offers the ultimate accuracy for net weight labeling but can be slower and more complex.

Operational Considerations: Cleaning and Maintenance

Piston fillers are designed with sanitation in mind, and most can be easily disassembled without tools for thorough cleaning. However, they have more moving parts and seals in the product path than a peristaltic pump filler.

Proper maintenance of the piston seals is critical to prevent leaks and maintain accuracy over the machine's lifespan.

Making the Right Choice for Your Product

Selecting the correct filling technology requires aligning the machine's strengths with your primary production goal.

- If your primary focus is accuracy with thick or chunky liquids (creams, honey, sauces): A piston filler is the industry standard for its precision and power.

- If your primary focus is sterility or handling sensitive products: A peristaltic pump filler offers superior product isolation and easier sanitation.

- If your primary focus is guaranteeing net weight regardless of density changes: A weighing filler provides the most accurate solution by filling to a specific weight.

By understanding the mechanics behind each technology, you can confidently select the right tool for your specific application.

Summary Table:

| Feature | Advantage | Ideal For |

|---|---|---|

| Positive Displacement | Forces product through, handles high viscosity | Honey, sauces, creams, pastes |

| Volumetric Accuracy | Consistent fill volume cycle after cycle | Precise product levels and labeling |

| Two-Stroke Cycle | Simple, reliable mechanical operation | Dependable high-speed production |

| Handles Particulates | Can fill products with chunks or seeds | Salsas, fruit preserves, lotions with exfoliants |

Need a reliable filling solution for your apiary or distribution business?

At HONESTBEE, we specialize in supplying durable, high-performance beekeeping and processing equipment to commercial apiaries and distributors. A piston filler is the perfect match for accurately and efficiently bottling your honey, propolis, and other viscous hive products.

Contact our experts today to discuss how our wholesale-focused solutions can enhance your packaging line's speed, accuracy, and profitability.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What are the characteristics of Semi-automated honey filling machines? Boost Efficiency for Growing Apiaries

- What are the primary challenges associated with the honey bottle filling process? Solve Viscosity and Accuracy Issues

- What are the principles of honey filling machines? Optimize Your Production for High-Viscosity Honey

- What is a key feature of the new generation of the honey filling machine? The Advanced Electronic Control Unit

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- How do automated honey filling machines facilitate brand value addition? Scale Your Apiary into a Premium Retail Brand

- How do industrial-grade automatic honey filling machines enhance commercial value? Scale Your Apiary Efficiency

- How do professional honey packaging and filling equipment enhance the market competitiveness of bee products?