Filling & Bottling

Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

Item Number : HFM-11

Price varies based on specs and customizations

- Output Efficiency

- 1600-1800 units/hour

- Power Supply

- Single Phase 220V (customizable to 110V)

- Construction

- Food-grade Stainless Steel, Aluminum Alloy

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

HONESTBEE, your trusted wholesale partner for comprehensive beekeeping tools and equipment, proudly presents our advanced Turntable Honey Spoon Filling & Sealing Machine. Designed specifically for commercial beekeeping operations and honey distributors, this robust Packing Machine automates the packaging process, ensuring efficiency, hygiene, and a professional finish for your honey products, whether in cups or spoon-like containers.

Professional Design & Enduring Durability

Constructed with high-quality, food-grade stainless steel and precision-engineered aluminum components, this machine is built for longevity and rigorous daily use in a commercial environment. Its polished finish and organized layout not in-only look professional but also facilitate easy cleaning and maintenance, crucial for food product handling. The robust framework minimizes vibration, contributing to consistent operational accuracy and a longer lifespan.

Key Design Features:

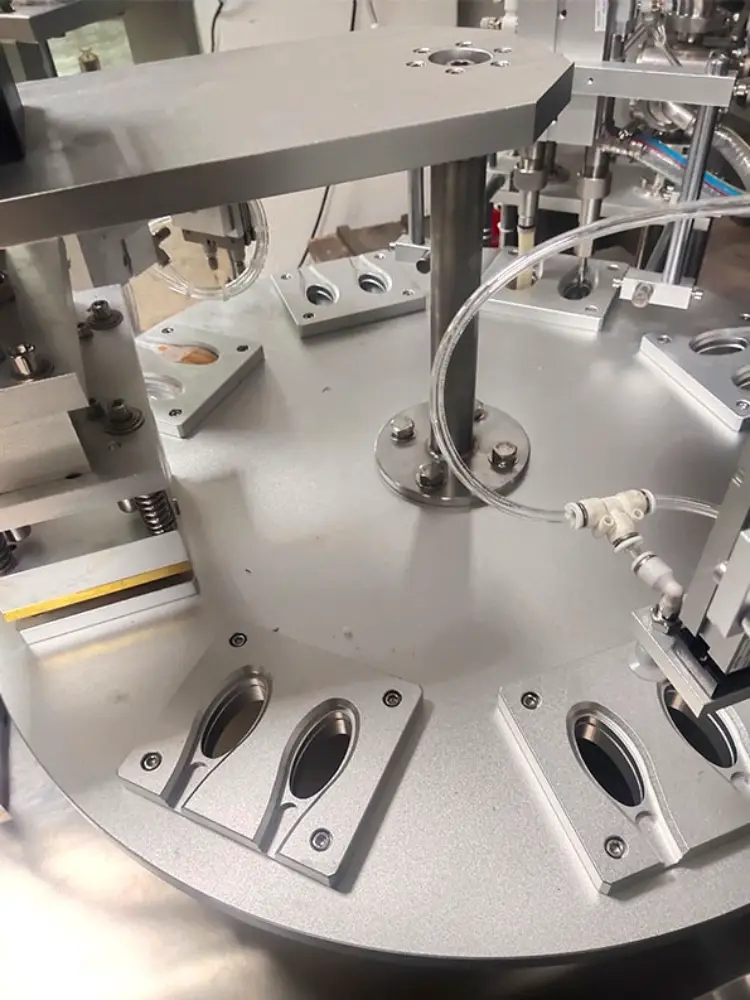

- Rotary Turntable System: Provides a compact footprint while maximizing throughput with multiple synchronized stations.

- Stainless Steel Construction: Offers excellent resistance to corrosion, is easy to sanitize, and meets food safety standards.

- Pneumatic & Electrical Components: High-quality, industry-standard parts ensure reliable and consistent performance. Air pressure regulators and filters ensure clean air supply for pneumatic operations.

Advanced Functionality for Optimized Honey Packaging

This machine integrates multiple functions into a seamless, automated workflow, significantly reducing manual labor and increasing output.

Operational Stages:

- Automatic Container Feeding: The system is designed to automatically dispense cups or spoons into the rotary turntable slots.

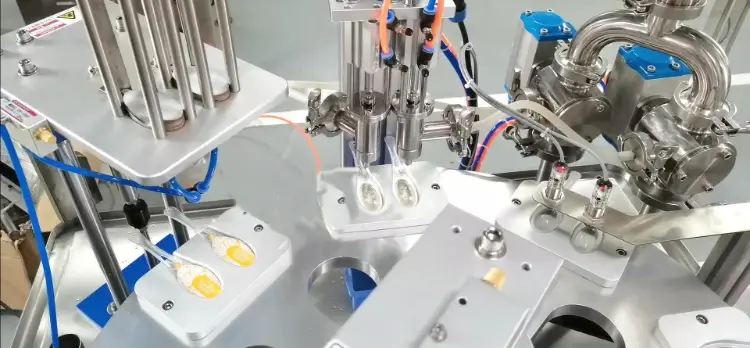

- Precision Filling: Equipped with a high-accuracy filling station, featuring dual nozzles for a two-cup-at-a-time output. This ensures consistent honey volume in each container, minimizing product wastage. The filling mechanism is designed for viscous liquids like honey.

- Automated Lid Placement: Pre-cut foil lids or films are precisely placed onto the filled containers.

- Secure Heat Sealing: A dedicated sealing station uses controlled heat and pressure to create an airtight, tamper-evident seal. The temperature is precisely controlled for optimal sealing without damaging the container or product.

- Automatic Ejection: Finished, sealed products are automatically ejected from the turntable, onto an output conveyor for collection or further processing.

User Interface & Control:

- DELTA HMI Touchscreen: A user-friendly Human-Machine Interface (HMI) provides intuitive control over all machine functions. There are options for language selection (Chinese/English), manual control of individual stations (Load Cup, Filling, Load Lid, Sealing, Exit), production count, auto/start/stop, and parameter settings.

- Emergency Stop: Prominently placed for immediate shutdown, ensuring operator safety.

- Clear Status Indicators: Digital temperature displays and on-screen indicators provide real-time operational status.

Advantages and Client Value

- Increased Efficiency: With an output of 1600-1800 units per hour (for the 2-up configuration), this machine dramatically boosts production capacity compared to manual or semi-automatic methods.

- Consistency & Quality: Automated processes ensure uniform filling, precise lid placement, and consistent sealing quality, enhancing product presentation and shelf-life.

- Reduced Labor Costs: Automation minimizes the need for manual intervention, freeing up labor for other critical tasks.

- Hygienic Operation: Minimized human contact with the product and easy-to-clean surfaces help maintain high hygiene standards.

- Professional Product Presentation: Securely sealed, uniformly filled containers enhance brand image and consumer confidence.

Customization to Meet Your Needs

At HONESTBEE, we understand that every operation has unique requirements. This Turntable Honey Spoon Filling & Sealing Machine can be tailored to your specific needs:

- Voltage Customization: Standard single-phase 220V, with customization available for single-phase 110V.

- Output Capacity: While the regular machine processes two cups simultaneously, we can engineer solutions for 3-cup, 4-cup, or even higher outputs to match your production scale.

- Container Specificity: The machine can be adapted for various shapes and sizes of honey spoons, cups, or other small containers. Molds and handling mechanisms will be customized accordingly.

- Filling Volume: Adjustable to accommodate different product sizes.

Application Scenarios

This versatile Packing Machine is ideal for:

- Commercial apiaries packaging their own honey.

- Honey processing and packaging companies.

- Distributors of specialty food items.

- Businesses producing single-serve honey portions for the hospitality industry, retail, or gift packs.

- Can also be adapted for other similar viscous products like jams, sauces, or creams in small containers.

After-Sales Support & Spare Parts

HONESTBEE is committed to long-term partnerships. We provide comprehensive after-sales support, including the availability of all necessary spare parts and wear components to ensure your machine continues to operate at peak performance for years to come.

Summary of Key Specifications and Benefits

| Feature | Specification / Benefit |

|---|---|

| Machine Type | Turntable / Rotary Filling & Sealing Machine |

| Product | Honey (adaptable for other viscous liquids/pastes) |

| Containers | Cups, Honey Spoons, other small containers (customizable) |

| Control System | PLC with DELTA HMI Touchscreen (Multilingual) |

| Power Supply | Single Phase 220V (customizable to 110V) |

| Required Air Pressure | ≥0.7 MPa (client to provide air compressor) |

| Output Efficiency | 1600-1800 units/hour (for 2-up configuration, customizable for higher outputs) |

| Construction | Food-grade Stainless Steel, Aluminum Alloy |

| Key Functions | Automatic Container Feeding, Filling, Lid Placement, Heat Sealing, Product Ejection |

| Customization | Voltage, Output (2-cup, 3-cup, 4-cup), Container Type/Size |

| Benefits | Increased Efficiency, Consistency, Reduced Labor, Hygiene, Professional Presentation |

| Support | Spare parts, technical assistance |

Elevate Your Honey Packaging with HONESTBEE!

For commercial beekeepers and honey distributors looking to streamline operations, improve product quality, and enhance brand presentation, the HONESTBEE Turntable Honey Spoon Filling & Sealing Packing Machine is an invaluable investment.

Contact us today to discuss your specific packaging requirements, request a quote, or learn more about how we can customize this machine to perfectly suit your production needs. Let HONESTBEE help you package your honey with precision and professionalism!

FAQ

What Is The Principle Of A Honey Filtering Machine?

What Are The Advantages Of Using A Honey Filtering Machine?

What Are The Applications Of A Honey Filtering Machine?

What Features Does A Honey Filtering Machine Offer?

4.9 / 5

This machine is a game-changer! Super efficient and saves so much time. Worth every penny!

4.8 / 5

Incredible quality and durability. It’s been running non-stop with zero issues. Highly recommend!

4.7 / 5

Fast delivery and easy setup. The precision is unmatched—perfect for our honey packaging needs.

4.9 / 5

Top-notch technology! The automation is flawless, and the sealing is airtight every time.

4.8 / 5

Great value for money. This machine has doubled our production speed without compromising quality.

4.9 / 5

Impressive build and performance. The turntable design is genius—smooth and precise.

4.7 / 5

Love how user-friendly it is! Even our team with minimal training can operate it effortlessly.

4.8 / 5

Reliable and sturdy. It’s been months, and it still works like new. No regrets!

4.9 / 5

The speed and accuracy are phenomenal. Our packaging has never looked this professional.

4.8 / 5

A fantastic investment. The sealing is perfect, and the machine is built to last.

4.7 / 5

Delivered faster than expected! The machine is compact yet powerful—exactly what we needed.

4.9 / 5

Cutting-edge technology at its best. Our productivity has skyrocketed thanks to this machine.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Fully Automatic Honey Filling Packaging Machine for Processing Line

Discover the efficient honey packaging machine for precise, hygienic, and automatic honey filling. Ideal for high-capacity production.

Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

HONESTBEE Rotary Honey Filling Machine: High-precision, semi-automatic solution for commercial beekeepers. PLC control, 0.1-0.5% accuracy, 1200 jars/hour. Boost productivity now!

Commercial Rotary Honey Filling Machine for Production

High-precision Rotary Honey Filling Machine for commercial apiaries. Boasts ±1g accuracy, 600 jars/hour capacity, and food-grade stainless steel construction. Boost efficiency now!

Semi Automatic Small Honey Bottle Filling Machine Honey Filler

Discover the semi-automatic honey filling machine, perfect for precise, efficient honey packaging. Versatile, user-friendly, and hygienic.

Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

Discover the Honey Bottling Machine for precise, hygienic honey packaging. Ideal for food, cosmetics, and pharmaceutical industries. Efficient and durable.

Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

Discover the honey sachet packing machine for precise, high-speed, and hygienic packaging solutions. Customizable, durable, and efficient.

Precision Honey Refractometer Instrument for Quality Assessment

HONESTBEE Honey Refractometer with ATC - precise moisture, Brix & Baumé measurements for beekeepers. Essential honey quality control tool. Buy now!

Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

Optimize honey extraction with our electric honey extractor, designed for efficiency, durability, and high-quality honey production. Perfect for beekeepers.

Commercial 48-Frame Stainless Steel Honey Extractor

Explore the **electric 48-frame honey extractor**, a durable stainless steel tool for efficient honey processing. Ideal for commercial beekeeping.

24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

Optimize honey extraction with our 24-frame stainless steel honey extractor. High-capacity, durable, and customizable for commercial beekeeping. Explore now!

Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

Optimize honey processing with our efficient honey filtering machine, featuring dual filtration, precise temperature control, and durable 304 stainless steel construction.

Automatic Honey Frame Uncapper Machine for Beekeeping

Boost honey extraction efficiency with our high-capacity Honey Uncapper Machine. Precision uncapping, durable 304 stainless steel, and customizable frame sizes ensure optimal results. Ideal for large-scale beekeeping operations. Explore now!

Spare Crank Gear Drivetrain Assembly for Manual 4 Frame Honey Extractor

Enhance your manual 4 frame honey extractor with our durable Spare Crank Gear Drivetrain Assembly. Ensure smooth, efficient honey extraction.

electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

Efficient electric honey extractor for beekeepers, stainless steel, 3-frame capacity, customizable sizes. Streamline honey extraction with ease.

Plastic Honey Gate Spout with Wing Nut for Beekeeping Honey Bucket

Optimize honey extraction with our durable, food-grade honey gate. Control flow, prevent leaks, and ensure purity. Perfect for all beekeepers.

Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

Premium inverted squeezable honey jar with no-drip cap. Convenient, mess-free dispensing in stylish retail packaging. Ideal for beekeepers & distributors.

Squeezable No-Drip Beehive-Shaped Honey Jars with Flip-Top Cap

Beehive-shaped squeezable honey jars with no-drip flip-top caps. Clear PET plastic, food-grade & shatterproof. Perfect for beekeepers & distributors.

Nicot Queen Rearing Kit for Beekeeping and Grafting in Nicot System

Efficiently raise queen bees with the Nicot Queen Rearing Kit. Simplify queen rearing, produce up to 110 queens, and ensure hive productivity. Ideal for all beekeepers.

No Grafting Queen Rearing Kit: System for Royal Jelly Production and Queen Rearing

Optimize your beekeeping with the Queen Rearing Kit. Efficiently rear queens and produce royal jelly. High-quality, versatile, and easy to use.

Related Articles

Are Manual Honey Filling Methods Bottlenecking Your Apiary's Growth?

Discover why manual honey filling costs more than you think in wasted product, labor, and lost sales, and how automation can transform your apiary.

How to Choose Between Gravity and Pump Feeding for Honey Filling Systems

Compare gravity vs. pump honey filling systems for viscosity handling, speed, and scale. Choose the right method for artisan or commercial production.

How to Choose a Honey Filling Machine That Grows With Your Business

Learn how to choose a scalable honey filling machine for long-term efficiency, compliance, and cost savings in your beekeeping business.

The Bottleneck and the Balance Sheet: A Strategic Guide to Honey Filling Machines

Choosing a honey filling machine is a strategic decision balancing capacity, material integrity, and the hidden long-term costs of ownership.

The Physics of Generosity: Why Your Honey Filling Machine Defines Your Profit Margin

Choosing a filling machine isn't about speed, but matching technology (volume, weight, level) to your product's properties to maximize accuracy and profit.

Your Honey Bottleneck Isn't the Filler. It's Everything Else.

Discover why a fast honey filler fails to increase output and how to fix the real bottlenecks in your packaging line for true growth.

How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines

Compare semi-automatic vs. fully automatic honey filling machines for cost, speed, and scalability to optimize your bottling line.

The Flow, The Fill, and The Future: A Honey Bottler's Guide to Scale

Choosing a honey filling machine isn't about specs; it's a strategic decision. Compare pump, piston, and gravity systems to match your operational goal.

How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines

Compare semi-automatic vs. fully automatic honey filling machines: costs, scalability & tech for beekeepers & commercial producers. Choose wisely!

The Bottleneck and the Bottom Line: A Systems Approach to Choosing Your Honey Filling Machine

Choosing a honey filler is a strategic decision balancing viscosity, accuracy, and operational philosophy. Learn how to pick the right system.

Beyond the Flow: The Physics and Psychology of Filling Honey Jars

Choosing a honey filler isn't just about speed. It's matching machine physics to product viscosity to protect your profit margins and brand trust.

The Bottleneck and the Bottle: A Systems Approach to Honey Filling

Choosing a honey filling machine isn't about features. It's about matching equipment to three core variables: product viscosity, production pace, and package type.