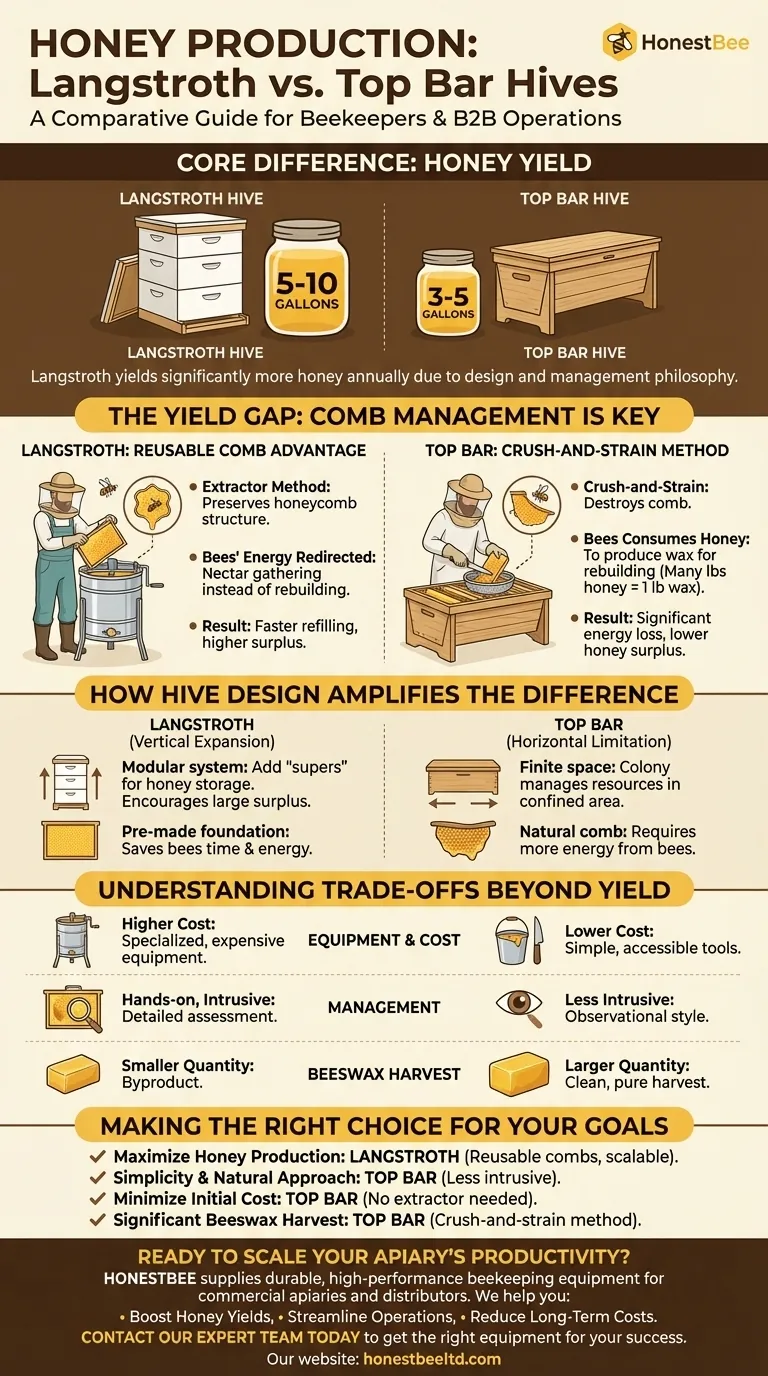

On average, a Langstroth hive will produce significantly more honey. A beekeeper can typically expect 5-10 gallons of honey annually from an established Langstroth colony, whereas a top bar hive will yield between 3-5 gallons. This difference is not accidental; it is a direct result of the fundamental design and management philosophy behind each hive.

The choice between a Langstroth and a top bar hive is less about which is "better" and more about defining your goals. Langstroth hives are engineered for maximum honey extraction and scalability, while top bar hives are designed for simplicity and a more natural, less-intrusive approach to beekeeping.

The Core Reason for the Yield Gap: Comb Management

The single greatest factor influencing honey production is how the honeycomb is handled during harvest. The energy bees expend to create wax is immense, and preserving this work is key to a larger honey surplus.

Langstroth: The Reusable Comb Advantage

In a Langstroth hive, honey is stored on removable frames. During harvest, the beekeeper uncaps the wax cells and places the entire frame into a centrifugal extractor.

This process spins the honey out while leaving the intricate and energy-intensive honeycomb structure completely intact. The bees can immediately refill these preserved combs, redirecting all their energy toward gathering nectar instead of rebuilding their pantry.

Top Bar: The Crush-and-Strain Method

Harvesting from a top bar hive involves cutting the entire comb from the top bar. This comb is then crushed and strained to separate the honey from the wax.

While simple and low-tech, this method destroys the bees' work. After every harvest, the colony must consume a significant amount of its own honey stores as energy to produce the wax needed to rebuild the comb from scratch.

The True Cost of Building Wax

Bees must consume many pounds of honey to produce just one pound of beeswax. By forcing the colony to constantly rebuild its comb, the top bar hive's harvest method directly reduces the amount of surplus honey available to the beekeeper.

How Hive Design Amplifies the Difference

Beyond the harvest, the physical structure of each hive is optimized for different outcomes, which further impacts potential honey yield.

Vertical Expansion and Scalability (Langstroth)

Langstroth hives are modular systems of stackable boxes. As a nectar flow begins, the beekeeper can easily add more boxes, called "supers," dedicated solely to honey storage.

This vertical expandability encourages the colony to gather and store far more honey than it needs for its own survival, creating a large surplus for the beekeeper.

Horizontal Limitation (Top Bar)

A top bar hive is a single, long, horizontal box. The colony expands sideways along the bars, but the overall space is finite.

There is no simple way to add dedicated "honey-only" space, so the colony naturally manages its resources within a more confined area, leading to a smaller surplus.

Foundation vs. Natural Comb

Langstroth frames often use a pre-made foundation imprinted with a cell pattern. This gives the bees a significant head start, saving them time and energy in constructing the comb.

Top bar hives encourage bees to build natural, foundationless comb. While many consider this a more organic approach, it requires more time and energy from the bees, slightly reducing their production pace.

Understanding the Trade-offs Beyond Honey Yield

Choosing a hive based solely on honey production ignores the critical differences in cost, labor, and beekeeping philosophy.

Equipment and Cost

The Langstroth's high yield comes with a price. It requires specialized and often expensive equipment, most notably a honey extractor that can cost hundreds of dollars.

Top bar harvesting, by contrast, requires little more than a bucket, a knife, and a strainer—tools most people already have.

Management and Intrusiveness

A Langstroth hive is designed for hands-on management, with frame-by-frame inspections. This allows for detailed colony assessment but is also more disruptive to the bees.

Top bar hives are geared toward a less-intrusive, more observational style of beekeeping, which many feel is less stressful for the colony.

The Value of a Beeswax Harvest

While a top bar hive produces less honey, the crush-and-strain method yields a much larger quantity of clean, pure beeswax. This valuable byproduct can be sold or used for candles, balms, and other crafts.

Making the Right Choice for Your Goals

Your beekeeping goals should dictate your choice of hive, not just the potential honey output.

- If your primary focus is maximizing honey production: The Langstroth hive is the undisputed choice due to its reusable combs and scalable design.

- If your primary focus is simplicity and a natural approach: The top bar hive is ideal, offering a less intrusive experience at the cost of a lower honey yield.

- If your primary focus is minimizing initial cost and equipment: The top bar hive is far more accessible, as it eliminates the need for an expensive honey extractor.

- If you value a significant secondary beeswax harvest: The top bar hive's harvesting method will provide you with substantially more beeswax than a Langstroth.

Ultimately, select the hive that best aligns with your philosophy and the level of involvement you wish to have with your bees.

Summary Table:

| Feature | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Average Annual Honey Yield | 5-10 gallons | 3-5 gallons |

| Harvest Method | Reusable comb (Extractor) | Crush-and-Strain |

| Key Advantage | Maximum honey production & scalability | Simplicity, low cost, natural approach |

| Beeswax Byproduct | Smaller quantity | Larger, pure harvest |

| Best For | Commercial focus, high yield | Hobbyists, low-intervention beekeeping |

Ready to Scale Your Apiary's Productivity?

Whether you manage a commercial operation or supply equipment to distributors, choosing the right hive is critical for maximizing efficiency and profit. HONESTBEE supplies the durable, high-performance beekeeping supplies and equipment that commercial apiaries and distributors rely on.

We help you:

- Boost Honey Yields with Langstroth hives designed for maximum production.

- Streamline Operations with reliable, wholesale-focused equipment.

- Reduce Long-Term Costs with durable gear built for commercial use.

Let's discuss your specific needs. Contact our expert team today to get the right equipment for your success.

Visual Guide

Related Products

- Professional Hive Top Bee Feeder for Beekeeping

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Telescopic Beehive Outer Cover Lid Roof with Galvanised Sheeting for Langstroth Hive and Beehive Outer Cover

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Round Hive Top Bee Feeder for Syrup

People Also Ask

- What types of hive boxes is the round hive top feeder compatible with? Universal Fit for 8 & 10-Frame Langstroth Hives

- What is the best bee feeder for a hive? Choose the Right Feeder for Your Apiary's Scale

- How to use a top feeder in a beehive? A Guide to Effective Beehive Feeding

- Do I need an inner cover with a hive top feeder? Optimize Your Hive Setup for Healthy Bees

- What are the advantages of hive top feeders? Maximize Feeding Efficiency for Your Apiary