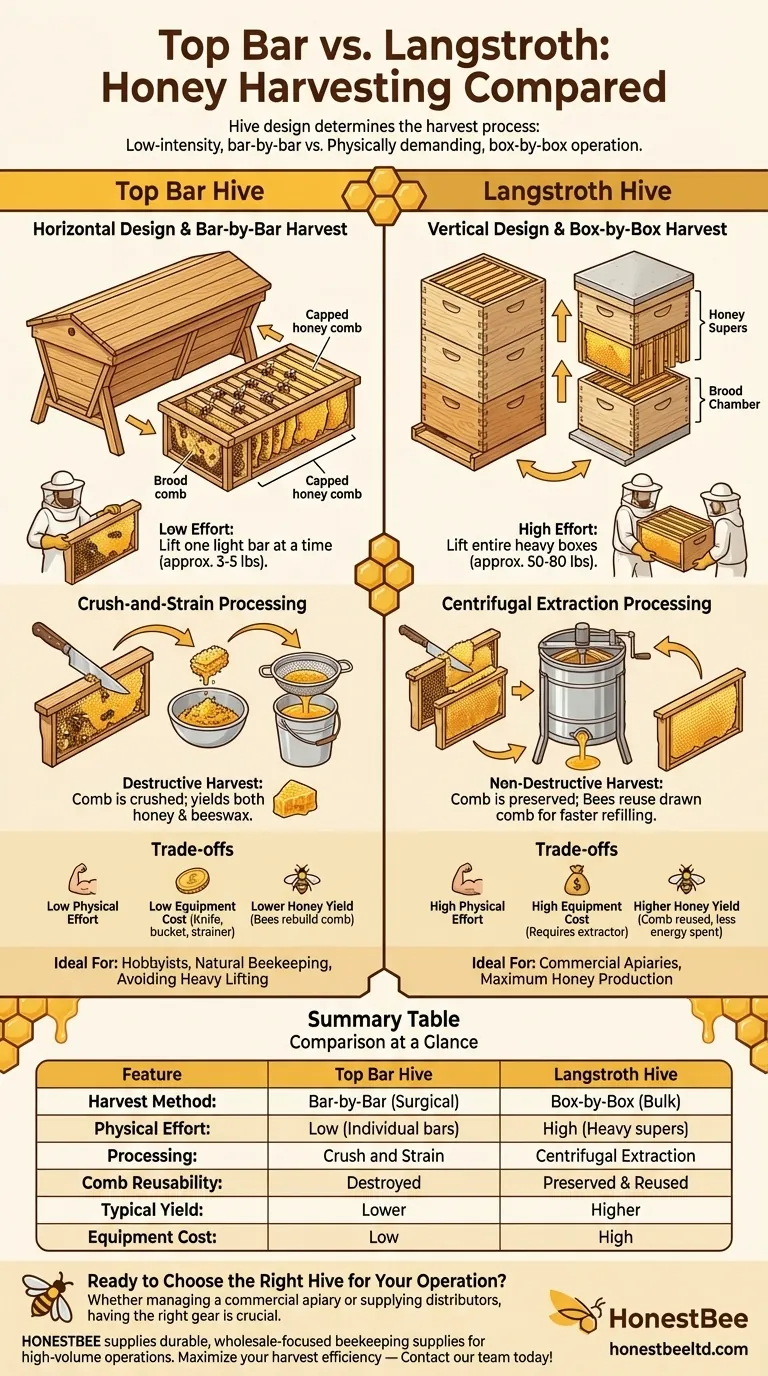

Fundamentally, the honey harvesting process is a direct reflection of each hive's design: Top Bar hives involve a low-intensity, bar-by-bar harvest, while Langstroth hives require a more physically demanding, box-by-box operation. In a Top Bar hive, you remove individual combs of honey one at a time. In a Langstroth, you must lift and remove entire heavy boxes, called "supers," each containing multiple frames of honey.

The core difference comes down to a choice between process and production. The Top Bar hive prioritizes a simpler, less physically strenuous harvest, while the Langstroth hive is engineered for maximum honey yield and efficiency, which demands more specialized equipment and physical effort.

Hive Architecture Dictates the Harvest

The structure of the hive is the single most important factor determining how you will collect honey. The horizontal design of the Top Bar and the vertical design of the Langstroth create two entirely different workflows.

The Horizontal Top Bar Hive

A Top Bar hive is a single, long horizontal box covered with wooden bars. Bees build their comb directly down from these bars in a natural, unsupported shape.

The bees organize the hive logically, with the queen laying eggs (brood) in the combs at the front and storing honey in the combs at the back. This creates a clear separation for harvesting.

The Vertical Langstroth Hive

A Langstroth hive is a system of vertically stacked boxes. Each box contains removable frames that provide a rigid structure for the bees to build their comb within.

Brood is typically in the lower boxes, and beekeepers add upper boxes (honey supers) specifically for honey storage. This modular design allows the hive to expand vertically as the colony grows.

The Harvesting Process, Step-by-Step

The architectural differences lead to distinct harvesting methods—one focused on surgical removal and the other on bulk collection.

Top Bar: A Bar-by-Bar Approach

Harvesting from a Top Bar hive is a continuous, small-scale process. You simply open the back of the hive, where the honey is, disturbing the brood nest very little.

You then select a single, heavy bar full of capped honey, gently brush the bees off, and cut the comb away from the wooden bar. The empty bar can be returned to the hive for the bees to use again.

Langstroth: A Box-by-Box Operation

Harvesting from a Langstroth hive is an event. It involves removing one or more entire honey supers, each of which can weigh between 50 and 80 pounds.

The beekeeper must lift these heavy boxes off the hive and transport them to a separate location for processing. This is a significant physical undertaking that often requires a strong back or assistance.

Processing: Crush-and-Strain vs. Centrifugal Extraction

How you separate the honey from the wax is the final, and perhaps most significant, difference.

The Top Bar Method: Crush and Strain

Because Top Bar comb is not supported by a frame, the only practical way to harvest the honey is the "crush and strain" method.

The comb is cut from the bar, crushed, and placed in a sieve or cheesecloth. Gravity then slowly separates the liquid honey from the beeswax. This process destroys the comb but yields a valuable secondary product: beeswax.

The Langstroth Method: Centrifugal Extraction

The frames in a Langstroth hive allow for a non-destructive harvest. After slicing off the wax cappings, the frames are placed in a machine called a honey extractor.

The extractor uses centrifugal force to spin the honey out of the comb's cells, leaving the delicate wax structure intact. These empty "drawn" combs can be returned to the hive, saving the bees immense time and energy as they do not have to rebuild them from scratch.

Understanding the Trade-offs

Neither method is inherently superior; they are optimized for different goals and priorities. Understanding the trade-offs is key to making the right choice.

Effort and Physicality

The Top Bar hive is the clear winner for anyone concerned with heavy lifting. Harvesting involves lifting one bar at a time, weighing only a few pounds. The Langstroth hive requires lifting heavy, awkward boxes.

Equipment and Cost

Top Bar harvesting is inexpensive. You need little more than a knife, a bucket, and a strainer. Langstroth harvesting requires a significant investment in a honey extractor, which can be costly.

Honey Yield and Bee Energy

The Langstroth hive is designed for higher honey production. By preserving the drawn comb, the bees can immediately begin refilling it with honey instead of consuming resources to produce wax and rebuild. This leads to larger, faster honey crops.

Philosophy and Hive Intrusion

The Top Bar method is often favored by those practicing "natural" beekeeping. It is seen as less intrusive because you only inspect or remove a small part of the hive at once. The crush-and-strain method also provides a natural yield of both honey and wax.

Making the Right Choice for Your Goal

Your personal goals as a beekeeper should dictate your choice of hive and its corresponding harvest method.

- If your primary focus is simplicity and avoiding heavy lifting: The Top Bar hive is the ideal choice for its manageable, bar-by-bar process.

- If your primary focus is maximizing honey production: The Langstroth hive is the industry standard for a reason, as preserving comb with an extractor significantly boosts yield.

- If your primary focus is a low-cost, natural approach: The Top Bar hive's crush-and-strain method requires minimal gear and provides both honey and beeswax.

Ultimately, choosing a hive is about aligning the beekeeping workload with your physical abilities and desired outcomes.

Summary Table:

| Feature | Top Bar Hive | Langstroth Hive |

|---|---|---|

| Harvest Method | Bar-by-Bar (Surgical) | Box-by-Box (Bulk) |

| Physical Effort | Low (Lift individual bars) | High (Lift heavy supers) |

| Processing Method | Crush and Strain | Centrifugal Extraction |

| Comb Reusability | Comb is destroyed | Comb is preserved and reused |

| Typical Yield | Lower | Higher |

| Equipment Cost | Low (Knife, bucket, strainer) | High (Requires honey extractor) |

| Ideal For | Hobbyists, natural beekeepers, those avoiding heavy lifting | Commercial apiaries, beekeepers focused on maximum honey production |

Ready to Choose the Right Hive for Your Operation?

Whether you manage a commercial apiary or supply beekeeping equipment distributors, having the right gear is crucial for an efficient harvest. HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment tailored for high-volume operations.

We can help you equip your beekeeping business for success, from Langstroth hive components for maximum yield to essential tools for any operation.

Maximize your harvest efficiency — Contact our team today to discuss your wholesale needs!

Visual Guide

Related Products

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What are the box management requirements for a top bar hive vs. Langstroth? Choose Your Hive Strategy

- What are the most popular types of hives besides the Langstroth? Top Bar & Horizontal Hives Explained

- What are the ergonomic and management advantages of Horizontal Top-Bar Hives? Modern Beekeeping with Less Strain

- What are the specific environmental challenges of using a horizontal Top Bar hive in cold climates? Survival Strategies

- What are the benefits of the top bar hive? A Guide to Ergonomic, Natural Beekeeping