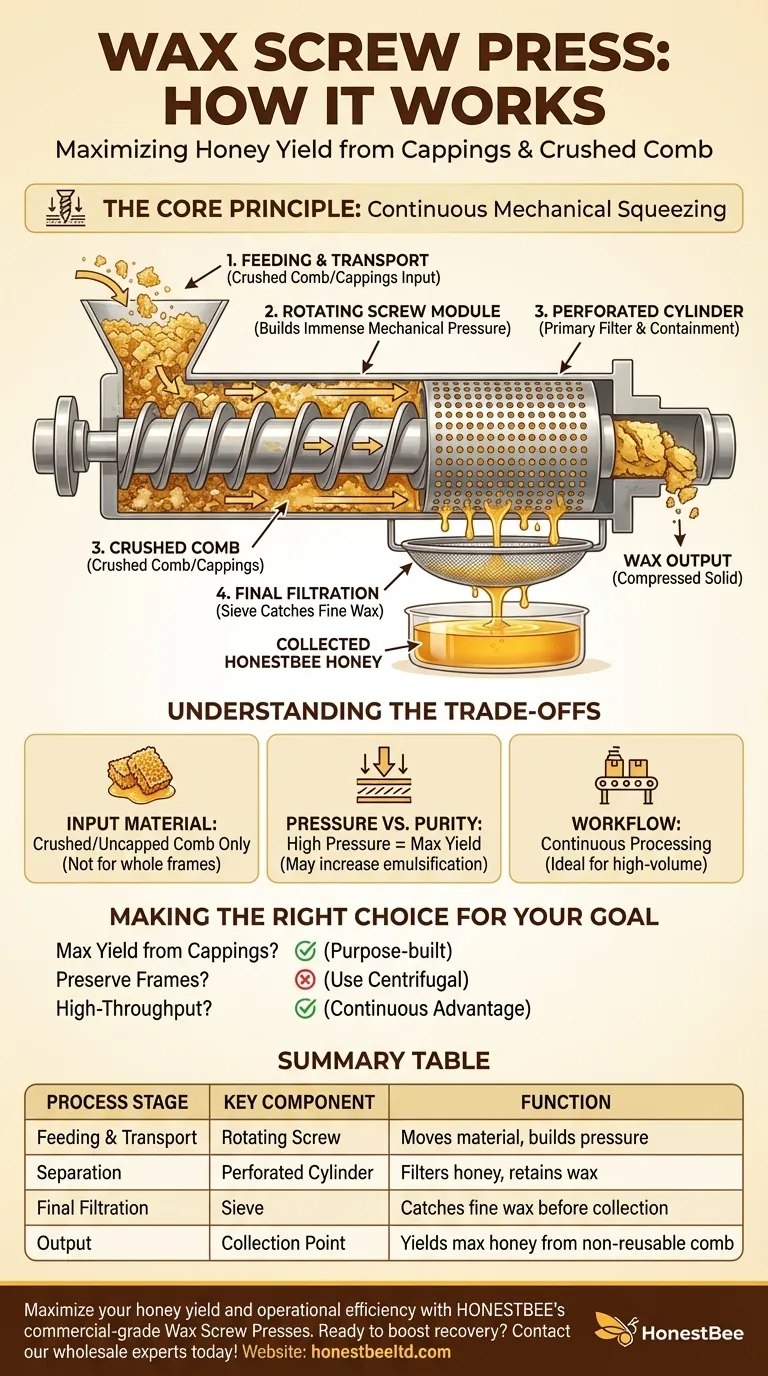

In short, a Wax Screw Press works by mechanically squeezing honey from uncapped comb. A rotating screw inside a perforated cylinder generates immense pressure, forcing liquid honey out through small holes while retaining the solid wax. The separated honey is then collected after passing through a final sieve.

The core principle of a Wax Screw Press is mechanical separation through direct pressure, not centrifugal force. This design is specifically engineered to maximize honey extraction from crushed or uncapped comb material in a continuous process.

The Core Mechanism: A Step-by-Step Breakdown

The entire process is a continuous mechanical flow designed for efficiency. It relies on a few key components working in concert to separate liquid honey from solid wax.

The Perforated Cylinder

The process begins inside the main housing, a perforated cylinder. This component acts as both a containment vessel and the primary filter.

Its walls are filled with small orifices or holes, large enough for honey to pass through but small enough to block the bulk of the beeswax.

The Rotating Screw Module

At the heart of the press is a rotating screw, often called a separating and pressing module or a separating shaft.

As this screw turns, it simultaneously transports the uncapped honey and comb material along the length of the cylinder and builds up immense pressure.

The Pressing Action

The key action is the steady increase in mechanical pressure. The screw's design compresses the wax and honey mixture against the inner walls of the perforated cylinder.

This direct pressure effectively squeezes the honey out of the wax cells, similar to wringing water from a sponge.

Separation and Collection

The extracted honey is forced through the orifices in the cylinder wall. It then drains downward onto a sieve located directly underneath the press.

This sieve provides a final stage of filtration, catching any larger wax particles that may have passed through the cylinder's perforations before the honey is collected.

Understanding the Trade-offs

While powerful, the screw press method has specific applications and consequences that differ significantly from other extraction techniques. Understanding these trade-offs is crucial.

Input Material is Key

A Wax Screw Press is not designed for whole, intact frames. It processes uncapped honey and crushed comb.

This makes it an excellent tool for processing wax cappings from a separate uncapping process or for any comb that is not suitable for reuse in the hive.

Pressure vs. Purity

The high pressure exerted by the screw is extremely efficient at extracting a maximum amount of honey.

However, this force can also emulsify more fine wax particles and pollen into the honey. This means post-extraction filtering and settling may be more critical than with honey from a gentle centrifugal extractor.

Continuous vs. Batch Processing

Unlike a centrifugal extractor which requires loading frames, spinning a batch, and then unloading them, a screw press allows for a more continuous workflow.

You can feed uncapped comb material into the machine continuously, making it highly suitable for larger-volume or commercial operations.

Making the Right Choice for Your Goal

To determine if this method fits your needs, consider your primary operational goal.

- If your primary focus is maximum yield from wax cappings: The screw press is purpose-built for this, ensuring you recover the highest possible amount of honey from material that is difficult to process otherwise.

- If your primary focus is preserving frames for reuse: This is the wrong tool. You need a centrifugal extractor, which removes honey while leaving the comb structure intact.

- If your primary focus is high-throughput processing: The continuous operation of a screw press offers a significant advantage for beekeepers managing a large number of hives.

Ultimately, the Wax Screw Press is a specialized tool that provides a powerful, mechanical solution for high-yield honey extraction from loose comb and cappings.

Summary Table:

| Process Stage | Key Component | Function |

|---|---|---|

| Feeding & Transport | Rotating Screw | Moves crushed comb/cappings forward while building pressure. |

| Separation | Perforated Cylinder | Allows honey to pass through small holes while retaining solid wax. |

| Final Filtration | Sieve | Catches any remaining wax particles before honey collection. |

| Output | Collection Point | Yields maximum honey from uncapped or non-reusable comb material. |

Maximize your honey yield and operational efficiency with HONESTBEE's commercial-grade Wax Screw Presses.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide durable, high-performance equipment designed for high-volume processing. Our Wax Screw Presses are engineered to deliver maximum extraction from cappings and crushed comb, ensuring you get the most value from every harvest.

Ready to boost your honey recovery rates? Contact our wholesale experts today to discuss the right equipment for your operation!

Visual Guide

Related Products

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

People Also Ask

- What is the optimal temperature for working with honeycomb when using a honey press? Maximize Flow & Quality

- How does the honey screw press operate? A Guide to Maximizing Honey Yield from Cappings

- How long does it take for beeswax to separate from honey? A Guide to Efficient Harvesting

- How does a Wax Screw Press separate honey from wax? Maximize Your Honey Yield with Mechanical Efficiency

- How is the honey press cleaned and maintained? Essential Tips for Longevity and Hygiene

- What is the function of a manual honey presser? Expert Honey and Wax Separation for Traditional Hives

- What is the use of a honey presser? A Simple, Versatile Tool for Small-Scale Beekeepers

- What are the advantages of using a honey press? Affordable, Versatile Harvesting for Small-Scale Beekeepers