Bottle Capping Machine

Automatic Inline Spindle Bottle Capping Machine for Honey Production

Item Number : BCM-3

Price varies based on specs and customizations

- Production Speed

- 20-40 PCS/MIN

- Suitable Bottle Height

- 30-300mm

- Suitable Bottle Diameter

- 20-160mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

At HONESTBEE, we understand that scaling your beekeeping operation from a passion to a profitable business requires efficiency and consistency. Manual bottling and capping can be a significant bottleneck, leading to increased labor costs, inconsistent seals, and slower production. We are proud to introduce our robust and reliable Bottle Capping Machine, designed to automate your packaging line and elevate your brand's professionalism.

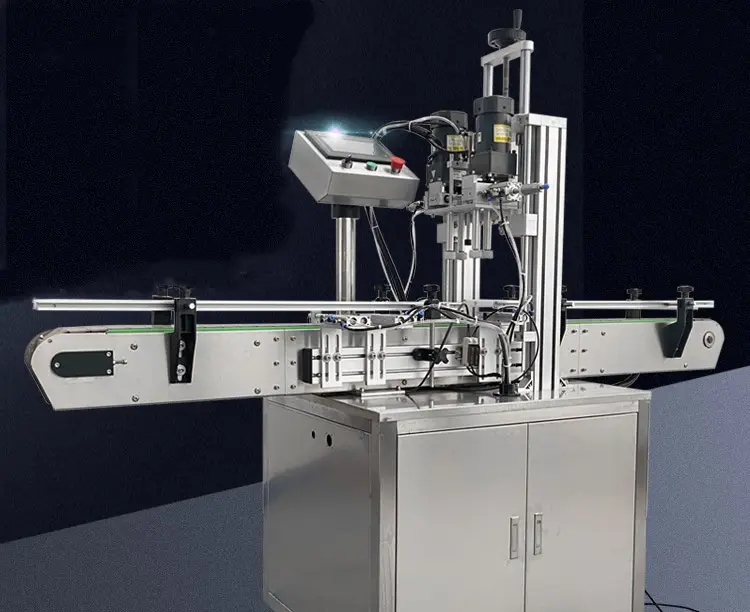

This fully automatic Bottle Capping Machine is engineered for high-performance, durability, and versatility, making it the perfect investment for commercial beekeepers and honey distributors.

Key Features & Professional Design

Our Bottle Capping Machine is built with industrial-grade components and a thoughtful design that focuses on functionality, durability, and ease of use.

1. High-Performance, Damage-Free Capping

- Automated Spindle System: The machine features a powerful four-wheel spindle capping structure. This system provides a firm, consistent torque that tightens caps securely without slipping or causing damage to the cap or bottle. It effectively resolves the challenges of tightening various cap types, including standard screw-tops, pump heads, and squeeze-tops often used for honey and bee products.

- Adjustable Torque & Speed: The capping speed and tightness are fully adjustable via the user-friendly interface, allowing you to achieve the perfect seal for every type of container, from delicate glass jars to sturdy plastic bottles.

2. Robust Construction & Durable Components

- Stainless Steel Body: The machine is constructed on a sturdy stainless steel base cabinet, ensuring long-term durability, resistance to corrosion, and easy cleaning—essential for a food-grade environment.

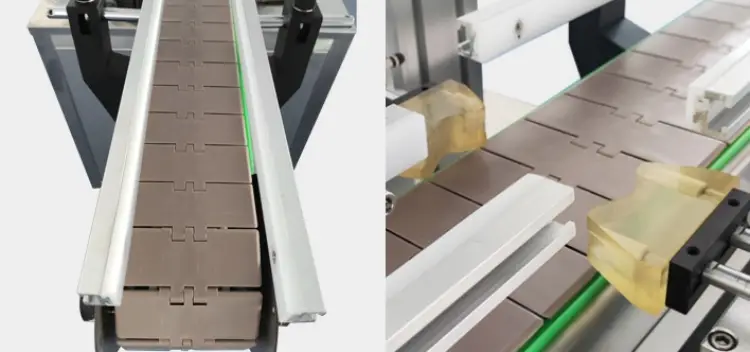

- Chain Plate Conveyor Belt: Unlike standard rubber belts, our Bottle Capping Machine utilizes a heavy-duty chain plate conveyor. This offers a longer service life, higher load-bearing capacity, and stable, adjustable-speed transport of your products down the line.

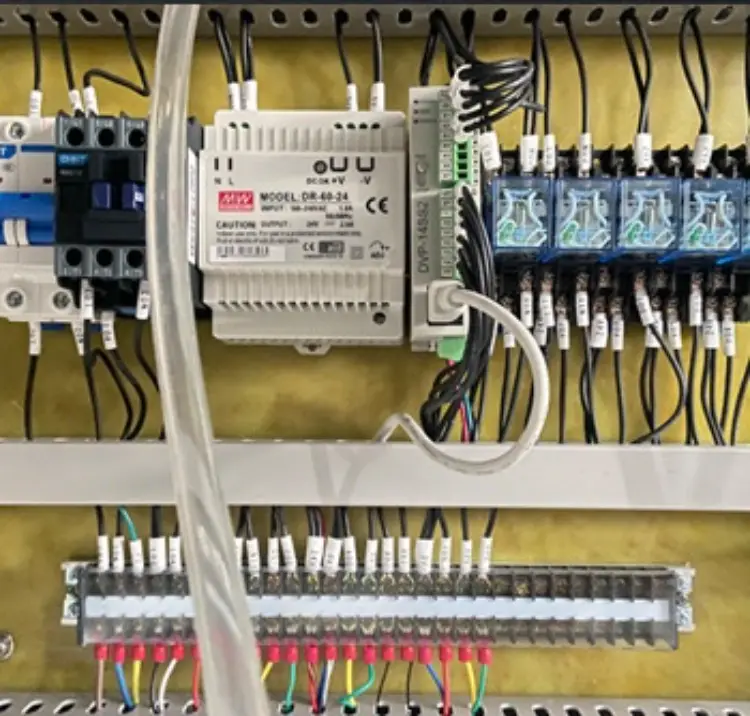

- High-Quality Electronics & Motors: We use reliable, branded electronic components and powerful motors. This guarantees strong performance, stable operation, and peace of mind, knowing your production line won't be interrupted by component failure.

3. Intelligent & User-Friendly Operation

- Intuitive Touchscreen Control: The integrated Delta PLC and touchscreen panel provide a central point of control. Operators can easily set and adjust parameters like conveyor speed and capping frequency, making operation simple and efficient.

- Automatic Bottle Handling: The machine is equipped with an automatic bottle separating device to space jars correctly on the conveyor and a bottle clamping system that securely holds the container in place during capping. This eliminates the need for manual positioning and ensures a perfect cap application every time.

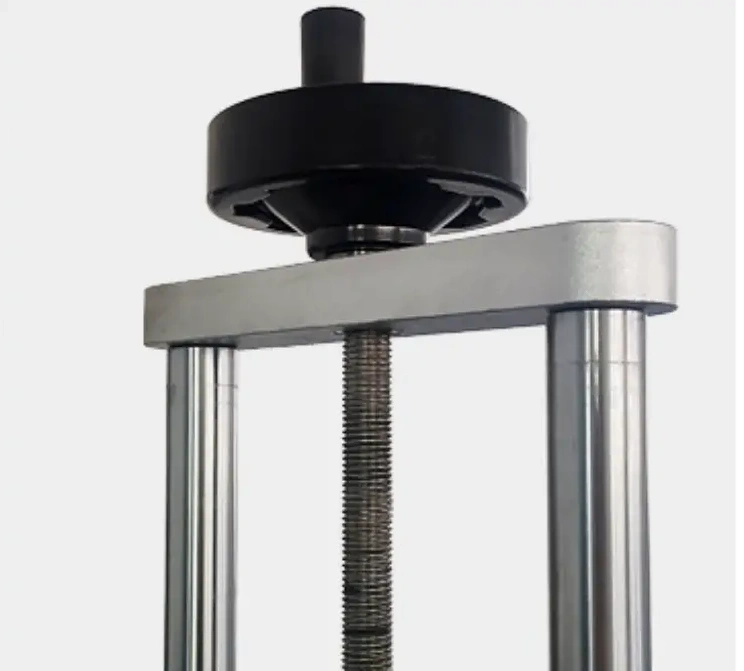

- Simple Height Adjustment: A large, manual handwheel allows for quick and easy adjustment of the capping head's height, accommodating a wide range of bottle and jar heights from 30mm to 300mm.

4. Safety and Versatility

- Emergency Stop: A prominent emergency stop button is located on the control panel for immediate shutdown, protecting both the operator and the machine during operation.

- Wide Application Range: This machine isn't just for a single product. It is designed to handle a variety of cap and bottle sizes, making it ideal for your entire product line—from standard honey jars to bottles of propolis tincture, lotion, and other value-added bee products.

Application in the Beekeeping Industry

This Bottle Capping Machine is an indispensable tool for any growing honey producer or distributor. Its versatility makes it suitable for:

- Glass and Plastic Honey Jars: Securely seal standard screw-on lids with consistent torque.

- Squeeze Bottle Honey: Perfectly cap plastic squeeze bottles with flip-top or nozzle caps.

- Value-Added Products: Efficiently cap bottles for propolis tinctures, honey-based sauces, beeswax lotions (with pump tops), and more.

- Various Cap Styles: Handles standard screw caps, pump caps, spray caps, and other threaded closures.

By automating this critical step, you increase your output, ensure a professional and tamper-evident seal on every product, and free up valuable labor to focus on other aspects of your business.

Product Specifications

Here is a summary of the technical specifications for our Automatic Bottle Capping Machine:

| Parameter | Specification |

|---|---|

| Power Supply | 220V / 110V 50-60HZ |

| Required Air Supply | 0.4-0.6MPA |

| Production Speed | 20-40 PCS/MIN |

| Suitable Bottle Height | 30-300mm |

| Suitable Bottle Diameter | 20-160mm |

| Suitable Cap Diameter | 18-70mm |

| Overall Dimensions | Approx. 2420mm * 680mm * 1700mm (L*W*H) |

| Machine Weight | Approx. 138KG |

Upgrade Your Packaging Line with HONESTBEE

Stop letting manual capping slow down your growth. Investing in our Automatic Bottle Capping Machine is an investment in efficiency, quality, and the future of your business. Increase your production capacity, reduce labor costs, and deliver a perfectly packaged product to your customers every time.

Contact the HONESTBEE wholesale team today to request a quote and learn how this essential piece of equipment can be integrated into your production line.

FAQ

What Is A Honey Spinner Used For?

What Is A Hive Tool Used For In Beekeeping?

What Are The Main Types Of Honey Spinners?

What Are The Main Features Of A Hive Tool?

How Does A Honey Spinner Work?

What Is The Principle Behind Using A Hive Tool?

What Are The Advantages Of Using A Honey Spinner?

What Are The Advantages Of Using A Hive Tool?

Why Is A Hive Tool Essential For Beekeepers?

4.9 / 5

This machine is a game-changer! Seals every bottle perfectly—no leaks, no fuss. Worth every penny!

4.8 / 5

Fast delivery and easy setup. The adjustable torque is brilliant for different bottle types.

4.7 / 5

Durable stainless steel construction—cleans easily and looks professional. Highly recommend!

5.0 / 5

The touchscreen controls are so intuitive. Our production speed has doubled effortlessly!

4.8 / 5

Love the chain plate conveyor—no more belt slippage. A solid investment for any honey business.

4.9 / 5

The automatic bottle handling is flawless. Saves so much time and reduces errors.

4.7 / 5

Compact yet powerful. Handles everything from glass jars to squeeze bottles with ease.

4.9 / 5

The emergency stop feature gives peace of mind. Safety and efficiency combined!

4.8 / 5

Perfect for small batches or large runs. Versatile and reliable—exceeds expectations.

4.9 / 5

The height adjustment wheel is genius. Swapping bottle sizes takes seconds!

4.7 / 5

Sturdy and quiet operation. Our honey line has never been smoother.

5.0 / 5

Tech-forward and built to last. Honestbee delivers top-tier equipment every time.

4.8 / 5

From unboxing to first use—flawless. This machine is a productivity powerhouse!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Semi Automatic Electric Bottle Capping Machine

Boost honey production with HONESTBEE's semi-automatic bottle capping machine. Durable, efficient, and adjustable for perfect seals every time.

Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

Boost packaging efficiency with HONESTBEE's semi-automatic bottle capping machine. Seals 30-45 bottles per minute, adjustable torque, durable aluminum alloy. Ideal for honey, food, cosmetics.

HONESTBEE 24 Head Rotary Bottle Washing Machine

Professional 24-head rotary bottle washing machine for commercial use. High-efficiency cleaning, stainless steel, 1800 bottles/hour. Ideal for beekeepers, beverage producers.

Semi Automatic Small Honey Bottle Filling Machine Honey Filler

Discover the semi-automatic honey filling machine, perfect for precise, efficient honey packaging. Versatile, user-friendly, and hygienic.

Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

Optimize honey packaging with our efficient Honey Filling Machine. Precise, fast, and easy to use. Boost production now!

Manual Honey Filling Machine Bottling Machine for Honey

Manual honey filling machine for precise, efficient packaging. Eco-friendly, durable, and customizable for small to medium-scale honey producers.

Commercial Rotary Honey Filling Machine for Production

High-precision Rotary Honey Filling Machine for commercial apiaries. Boasts ±1g accuracy, 600 jars/hour capacity, and food-grade stainless steel construction. Boost efficiency now!

Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

Optimize honey packaging with our sachet and filling machines. Ensure purity, efficiency, and precision for all honey types. Upgrade production now!

Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

HONESTBEE Rotary Honey Filling Machine: High-precision, semi-automatic solution for commercial beekeepers. PLC control, 0.1-0.5% accuracy, 1200 jars/hour. Boost productivity now!

Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

Boost honey production with our automatic honey filling machine. Efficient, precise, and user-friendly for high-quality bottling.

Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

Discover the Honey Bottling Machine for precise, hygienic honey packaging. Ideal for food, cosmetics, and pharmaceutical industries. Efficient and durable.

10L Stainless Steel Electric Honey Press Machine

10L Stainless Steel Electric Honey Press for efficient honey extraction. Durable, easy to clean, and preserves natural honey quality. Perfect for beekeepers.

Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

Optimize honey processing with our Homogenizer and Mixing Machine. Durable, efficient, and customizable for all scales. Perfect for beekeepers and manufacturers.

Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

Boost honey quality with our Honey Dehumidifier and Concentrating Machine. Efficient, durable, and hygienic for large-scale processing.

Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

Optimize honey quality with our Honey Concentrating and Dehumidifying Machine, designed for efficient moisture control and thickening. Explore now!

Beeswax Machine Press Embosser Wax Foundation Mold Printer Bee Hive Equipment Making Sheet

Discover the Beeswax Machine Press Embosser for precise, durable beeswax foundation sheets. Perfect for beekeeping, easy to use, and low maintenance.

Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

Electric beeswax foundation machine for beekeeping. High-quality, customizable wax sheets, 1200pcs/hour. Durable, efficient, and bee-friendly. Explore now!

Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

Economy manual beeswax embossing mill for beekeepers. Customizable wax foundation sheets, durable aluminum alloy, 300-600pcs/hour capacity. Enhance hive health and honey production.

Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

Boost beekeeping efficiency with our wax foundation machine. Produces 300-600 uniform sheets/hour. Customizable sizes, durable aluminum alloy. Ideal for healthy hives & increased honey production.

Fully Automatic Beeswax Embossing Machine Foundation Mill

Explore high-quality beeswax foundation machines for efficient beekeeping. Durable, customizable, and high-output at 1000 sheets/hour. Ideal for factory manufacturing.

Related Articles

Your Honey is Perfect. Your Bottle Sealing Isn't. Here's Why.

Stop losing profit to leaky jars and bottling bottlenecks. Discover the real reason your sealing process fails and how to choose the right capper.

Are Manual Honey Filling Methods Bottlenecking Your Apiary's Growth?

Discover why manual honey filling costs more than you think in wasted product, labor, and lost sales, and how automation can transform your apiary.

Why Manual Honey Labeling Is a Bottleneck to Growth—And How to Break Through

Stop losing profit to slow, inconsistent manual labeling. Learn how automation fixes the root cause of inefficiency to unlock growth for your honey business.

How to Choose Between Semi-Automatic and Automatic Honey Fillers for Optimal ROI

Compare semi-automatic vs. automatic honey fillers for ROI: production scale, cost savings, and scalability guide for apiaries.

Why Your Honey Bottles Look Inconsistent on the Shelf—And Why the Fix Isn't What You Think

Struggling with uneven honey fill levels? Discover the surprising reason it's not your filler's fault and how fill-to-level technology ensures perfect shelf appeal.

How to Choose a Honey Filling Machine: Balancing Efficiency, Customization, and Cost

Learn how to choose the right honey filling machine for efficiency, customization, and cost savings in commercial honey packaging.

How Advanced Honey Packaging Preserves Quality & Maximizes Profits for Beekeepers

Discover how advanced honey packaging preserves quality, prevents waste, and boosts profits for beekeepers with insulated barrels and precision tech.

Why Your Honey Filling Line is Failing—And It's Not the Machine's Fault

Struggling with inconsistent honey fills and production halts? Discover the real root cause and how to build a reliable, profitable bottling process.

How Automated Frame-Making Revolutionizes Beehive Production Efficiency

Discover how automated frame-making boosts beekeeping efficiency with precision grooving, tenon forming, and sustainable materials for healthier hives.

HonestBee Top & Bottom Bar Forming Machine: Precision Manufacturing for Beehive Frames

A specialized wood-forming solution for beehive frame manufacturers offering customizable precision cutting, end-shaping, and notching capabilities to enhance production efficiency.

The 40°C Rule: How Gentle Heat Protects the Soul of Your Honey

Learn why 40°C is the crucial temperature for warming honey. Exceeding it damages enzymes and flavor—a costly mistake for commercial beekeepers.

Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution