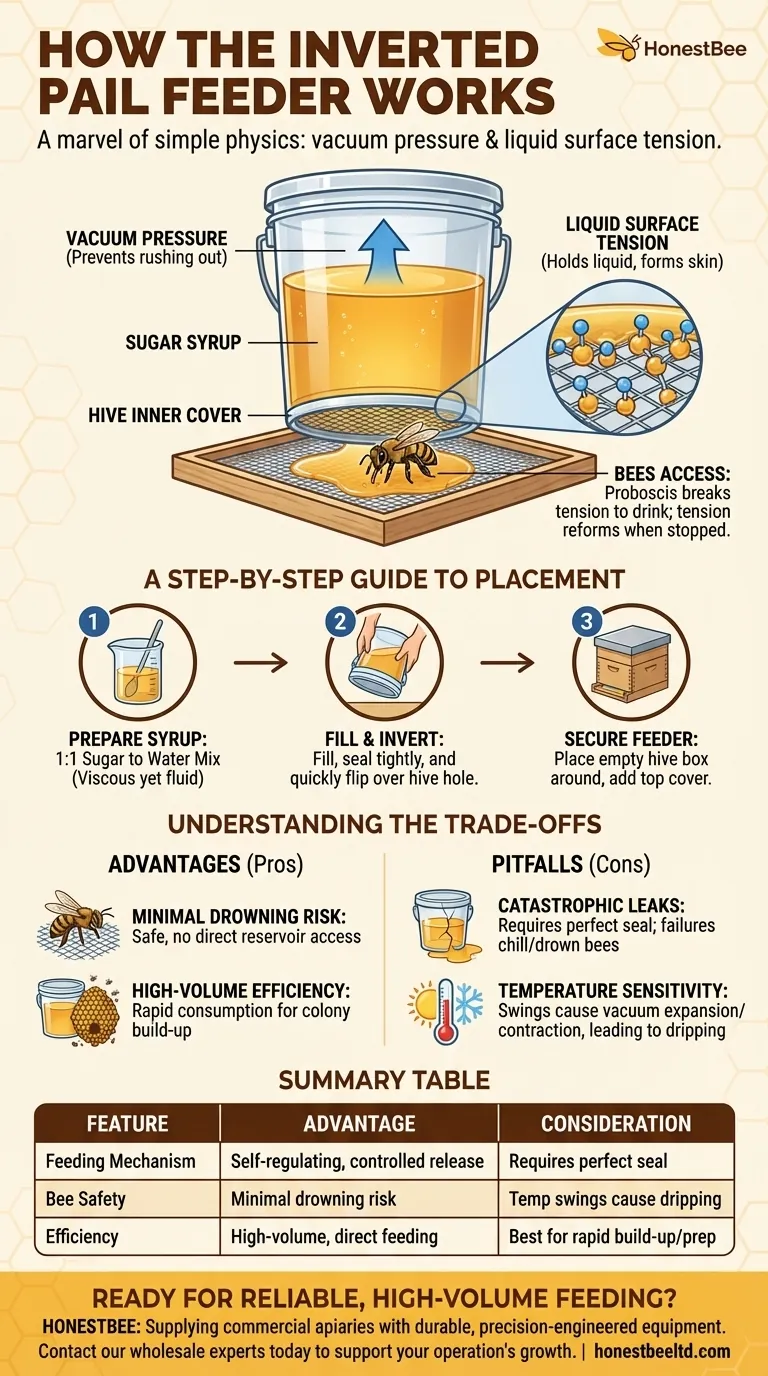

The inverted pale feeder is a marvel of simple physics, operating through a clever combination of vacuum pressure and liquid surface tension. When the pail of sugar syrup is flipped upside down over the hive, the vacuum created at the top prevents the syrup from rushing out. Simultaneously, the fine mesh on the lid creates enough surface tension to hold the liquid in place, allowing bees to drink as needed without causing a dangerous, sticky mess.

The core principle of the inverted pale feeder is its self-regulating design. It leverages natural forces to provide a slow, controlled release of syrup that minimizes waste and the risk of drowning bees, making it a highly efficient feeding method.

The Science Behind the Seal

To trust the system, it's essential to understand the two physical forces that make it work. These principles ensure the feed is delivered safely and only when the bees demand it.

Creating the Vacuum

When the sealed, full pail is inverted, the weight of the syrup tries to pull it down. This creates a low-pressure area, or vacuum, in the airspace at the top of the pail. This vacuum acts as a counterbalance, holding the column of syrup up and preventing it from draining freely.

The Role of the Mesh Screen

The fine mesh screen is the second critical component. The surface tension of the viscous sugar water causes the liquid molecules to cling to one another and to the edges of the screen. This creates a thin, flexible "skin" that is strong enough to contain the syrup against the pull of gravity.

How Bees Access the Syrup

Bees land on the screen and use their tongues (proboscis) to draw syrup through the mesh. This action breaks the surface tension at the precise point of contact, allowing them to drink. As soon as they stop, the surface tension reforms, and the vacuum ensures no further dripping occurs.

A Step-by-Step Guide to Placement

Proper setup is critical to prevent leaks and ensure the feeder functions correctly. The process is simple but must be done with care.

Prepare the Syrup

A 1:1 mixture of sugar to water is common for these feeders. This ratio creates a syrup that is viscous enough to maintain good surface tension but fluid enough for the bees to consume easily.

Fill and Invert

Fill the pail with the prepared syrup, leaving a small amount of airspace at the top. Secure the lid tightly to ensure an airtight seal, which is essential for the vacuum to form. Quickly and smoothly flip the pail upside down and place it over the hole in the hive's inner cover.

Secure the Feeder

An empty hive box (either a deep brood box or a shallow super) must be placed around the feeder. This collar protects the pail from the elements and prevents robber bees from other colonies from accessing the feed. Finally, place the hive's main top cover over the entire assembly.

Understanding the Trade-offs

Like any piece of equipment, the inverted pale feeder has distinct advantages and potential drawbacks that every beekeeper should consider.

Advantage: Minimal Drowning Risk

Because bees feed through a screen without direct access to a large reservoir of liquid, the risk of them falling in and drowning is virtually eliminated. This makes it one of the safest feeding methods.

Advantage: High-Volume Efficiency

These feeders deliver a large volume of food directly above the cluster. Studies have shown this can be a highly efficient method, with bees potentially consuming over half the pail's contents in a single day.

Pitfall: Potential for Catastrophic Leaks

The system's greatest weakness is its reliance on a perfect seal. If the lid is not on tight, the pail is cracked, or the seal is otherwise compromised, the vacuum will fail. This will cause the entire gallon of syrup to drain into the hive, which can chill the brood and drown a significant number of bees.

Pitfall: Temperature Sensitivity

Large temperature swings can cause the air in the vacuum to expand and contract. This can break the surface tension seal on the mesh, causing the feeder to drip. This is a crucial consideration during seasons with warm days and cold nights.

Making the Right Choice for Your Hive

Choosing a feeder depends entirely on your specific beekeeping goals and conditions.

- If your primary focus is rapid feeding: The inverted pale is ideal for quickly building up a new colony or preparing an established hive for winter due to its high volume and efficiency.

- If your primary focus is bee safety: This is one of the safest designs available, as the risk of bees drowning is extremely low compared to entrance or frame feeders.

- If your primary focus is feeding in fluctuating temperatures: You must be vigilant and check for leaks, as temperature swings can compromise the vacuum seal and cause dripping.

Ultimately, the inverted pale feeder offers a powerful and effective feeding method when its simple physical principles are understood and respected.

Summary Table:

| Feature | Advantage | Consideration |

|---|---|---|

| Feeding Mechanism | Self-regulating, controlled release | Requires a perfect seal to prevent leaks |

| Bee Safety | Minimal risk of drowning | Temperature swings can cause dripping |

| Efficiency | High-volume feeding directly over the cluster | Best for rapid colony build-up or winter prep |

Ready to ensure your apiary's success with reliable, high-volume feeding?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, precision-engineered supplies they need to thrive. Our inverted pale feeders are designed for maximum efficiency and bee safety, helping you build stronger colonies with confidence.

Contact our wholesale experts today to discuss your needs and discover how our equipment can support your operation's growth and productivity.

Visual Guide

Related Products

- HONESTBEE Round Hive Top Bee Feeder for Syrup

- Rapid Bee Feeder White Plastic 2L Round Top Feeder for 8 or 10-Frame Bee Hives

- HONESTBEE Entrance Bee Feeder Professional Hive Nutrition Solution for Beekeeping

- HONESTBEE Entrance Bee Feeder Efficient Hive Front Liquid Feeding Solution for Beekeeping

- Professional In-Hive Frame Bee Feeder by HONESTBEE

People Also Ask

- How do you use a top feeder for bees? Expert Guide to Installation and High-Volume Hive Feeding

- How do hive top feeders work? A Guide to Efficient, High-Capacity Bee Feeding

- How should the round hive top feeder be positioned? Master Internal Feeding for Stronger Colonies

- What are the features of top feeders for bees? Maximize Hive Health with Safe, High-Capacity Feeding

- What can the round hive top feeder be used for? A Guide to Efficient, Safe Bee Feeding