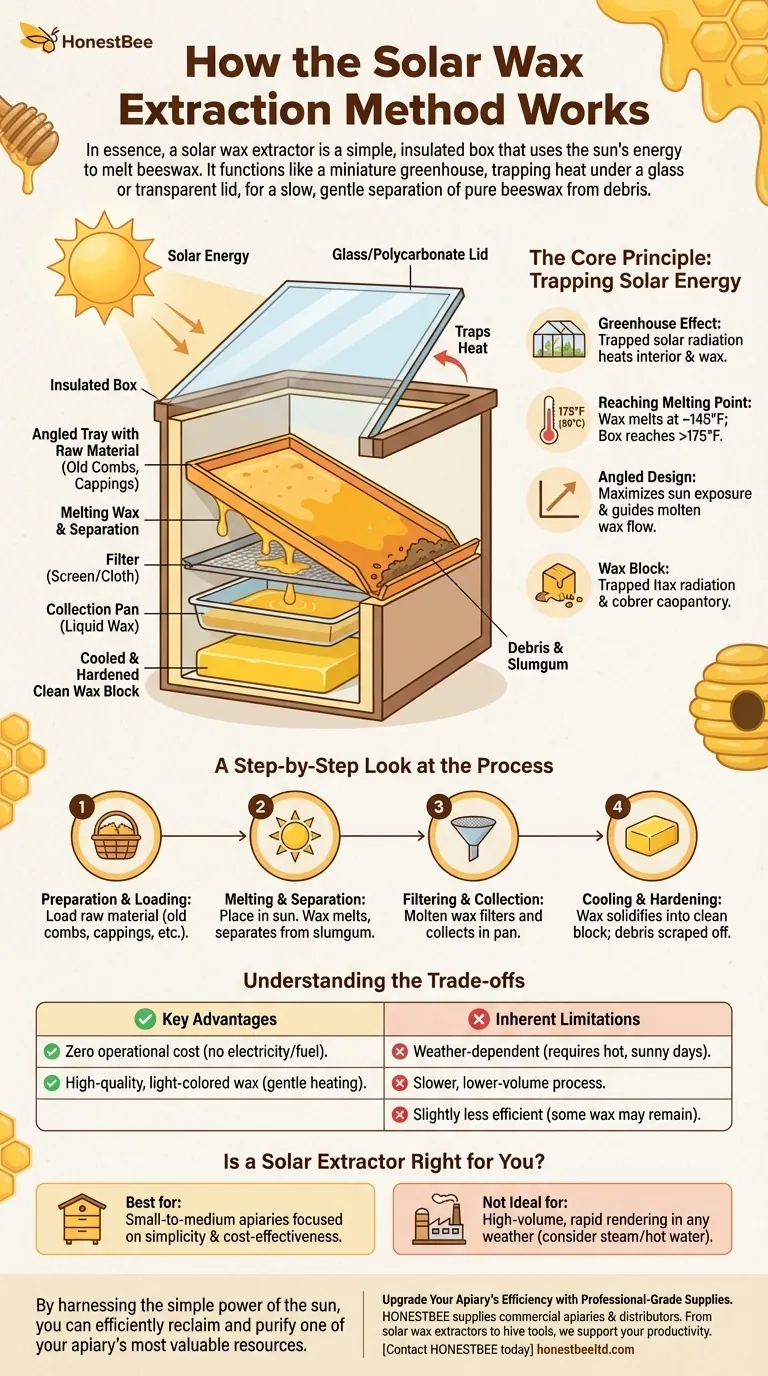

In essence, a solar wax extractor is a simple, insulated box that uses the sun's energy to melt beeswax. It functions like a miniature greenhouse, trapping heat under a glass or transparent lid. Old honeycombs or wax cappings are placed inside, and as the internal temperature rises, the wax melts, runs down an angled surface, passes through a filter, and collects in a pan as clean, liquid wax.

The core principle is leveraging passive solar energy for a slow, gentle, and low-effort method of separating pure beeswax from old combs and debris. It is a highly efficient process for small-scale beekeepers who value simplicity and wax quality over speed.

The Core Principle: Trapping Solar Energy

A solar extractor is a masterclass in simple, effective design. Its operation relies on a few fundamental physics principles working in concert.

The Greenhouse Effect in a Box

The extractor's transparent lid, typically made of glass or polycarbonate, allows solar radiation to enter the box. This energy heats the dark interior surfaces and the wax itself. The lid then traps this heat, preventing it from escaping and allowing the internal temperature to rise significantly above the ambient air temperature, much like a car parked in the sun.

Reaching the Melting Point

Beeswax has a melting point of approximately 144-147°F (62-64°C). A well-designed solar extractor can easily reach temperatures of 175°F (80°C) or higher on a hot, sunny day, ensuring a complete and efficient melt.

The Role of an Angled Design

The entire unit is designed to be angled towards the sun to maximize exposure. Inside, the tray or basket holding the old combs is also sloped. This angle serves two purposes: it ensures the comb material directly faces the sun, and it uses gravity to guide the molten wax downwards towards the filter and collection point.

A Step-by-Step Look at the Process

Understanding the workflow reveals the extractor's elegant simplicity from start to finish.

1. Preparation and Loading

The process begins by loading raw material into the extractor. This typically consists of old, dark brood combs, wax cappings from honey extraction, or burr comb scraped from hive components. The material is placed in a metal basket or on a tray.

2. The Melting and Separation Phase

The extractor is positioned in direct sunlight, optimally angled towards the sun's path. As the box heats up, the wax begins to melt. Because the molten wax is liquid, it flows away from the "slumgum"—the mix of old cocoons, pollen, and debris left behind in the comb.

3. Filtering and Collection

The sloped interior guides the liquid wax to a filter, often a simple screen or piece of cloth. This filter catches larger pieces of debris before the wax drips into a separate collection pan or mold placed at the bottom of the unit.

4. Cooling and Hardening

At the end of the day, the collection pan containing the pure, liquid wax is removed. As it cools, the wax solidifies into a clean, dense block, often with a brilliant yellow color. Any remaining fine debris typically settles at the bottom of the block and can be easily scraped off.

Understanding the Trade-offs

While effective, the solar method is not a universal solution. It's crucial to understand its advantages and limitations.

Key Advantages

The primary benefit is its zero operational cost. It uses free energy from the sun with no need for electricity or fuel. The slow, gentle heating process also produces exceptionally high-quality, light-colored wax because it avoids the scorching that can occur with other methods.

Inherent Limitations

This method is entirely weather-dependent; it is only effective on hot, sunny days. It is also a slower, lower-volume process compared to steam or hot water rendering, making it less suitable for large commercial operations. Finally, it can be slightly less efficient, sometimes leaving a small percentage of wax trapped in the slumgum.

Is a Solar Extractor Right for You?

Choosing a rendering method depends entirely on your apiary's scale and your primary goals.

- If your primary focus is simplicity and cost-effective processing for a small-to-medium apiary: The solar extractor is an outstanding choice that yields high-quality wax with minimal effort and no running costs.

- If your primary focus is high-volume, rapid wax rendering that works in any weather: You will be better served by a more industrial method, such as a steam melter or a hot water immersion system.

By harnessing the simple power of the sun, you can efficiently reclaim and purify one of your apiary's most valuable resources.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Uses the greenhouse effect to trap solar energy and melt wax. |

| Key Advantage | Zero operational cost; produces high-quality, light-colored wax. |

| Primary Limitation | Weather-dependent; slower and lower volume than industrial methods. |

| Ideal For | Small-to-medium apiaries focused on simplicity and cost-effectiveness. |

Upgrade Your Apiary's Efficiency with Professional-Grade Supplies

Reclaiming high-quality beeswax is just one part of a successful beekeeping operation. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed to thrive.

From solar wax extractors to essential hive tools, we provide the reliable equipment that supports your productivity and honey yield.

Contact HONESTBEE today to discuss your wholesale needs and discover how our products can benefit your business.

Visual Guide

Related Products

- Solar Beeswax Melter Easy Solar Wax Melter for Beeswax

- Electric Commercial Beeswax Melter for Factory Use

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Thermostatic Conical Honey Melter

People Also Ask

- Can the Solar Wax Melter operate on partly cloudy days? Harness Solar Power Effectively

- What is a solar wax melter and how does it work? Harness the Sun for Pure Beeswax

- What is the function of a solar wax melter for bee cocoons? Gentle Extraction for Scientific Analysis

- What are the main advantages of the solar waxing machine? Harness the Sun for Pure, Cost-Free Beeswax

- What are the main features of a solar wax melter? A Complete Guide to Sustainable Wax Rendering