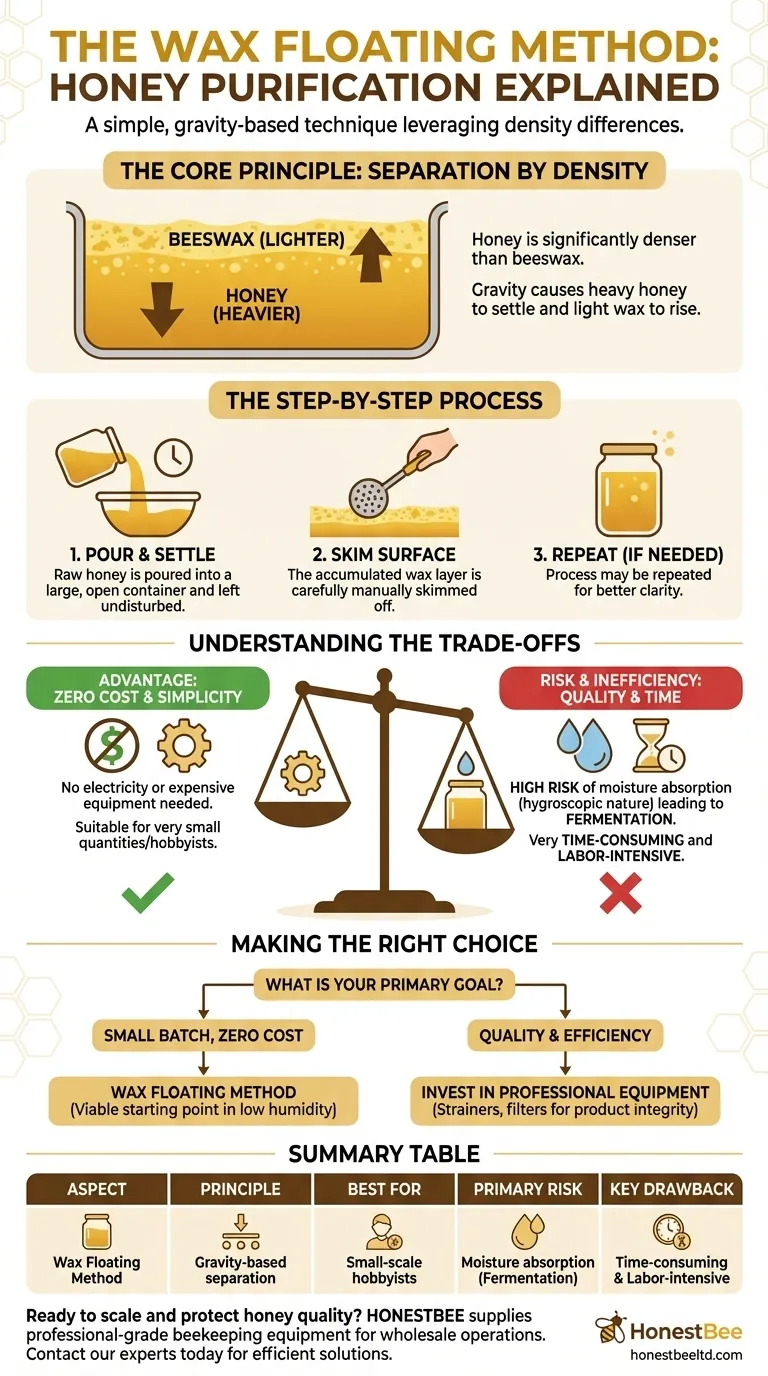

At its core, the wax floating method is a simple, gravity-based technique for purifying honey. It works by allowing raw honey to settle in a container, which causes the lighter beeswax particles to naturally float to the surface where they can be manually skimmed off.

This technique leverages the natural density difference between honey and wax, providing a no-cost purification solution that trades speed and precision for simplicity.

The Core Principle: Separation by Density

The entire method is built upon a fundamental law of physics: less dense materials float on top of more dense materials.

How It Works

Honey is significantly denser than beeswax. When a mixture of raw honey and wax particles is left undisturbed in a container, gravity takes over.

The heavier honey settles towards the bottom, while the lighter wax particles slowly rise to the top, forming a distinct layer that can be easily accessed.

The Step-by-Step Process

The process is straightforward and requires no specialized equipment.

First, the raw honey harvest is poured into a large, open container. The container is then left to sit undisturbed for a period of time.

Finally, the layer of wax that has accumulated on the surface is carefully skimmed off. This process may need to be repeated several times to remove as much wax as possible.

Understanding the Trade-offs

While simple, this method comes with significant drawbacks that directly impact the final product's quality and the producer's time.

The Advantage: Zero Cost and Simplicity

The primary appeal of the wax floating method is its accessibility. It requires no electricity or expensive processing facilities.

This makes it a suitable option for small-scale farmers or hobbyists who are processing very small quantities of honey and have no budget for equipment.

The Risk: Moisture Absorption

The most significant risk is honey's hygroscopic nature—its tendency to absorb moisture from the surrounding air.

By leaving honey in an open container for extended periods, especially during humid or rainy seasons, you expose it to moisture absorption. This increases the water content of the honey.

The Impact on Honey Quality

Increased water content degrades honey quality and dramatically shortens its shelf life. It creates an environment where fermentation can occur, spoiling the honey's flavor and commercial value.

The Inefficiency: Time and Labor

This is not a fast process. The settling can take a long time, and the manual skimming is a tedious, repetitive task. It is not a practical solution for anyone looking to process honey efficiently.

Making the Right Choice for Your Goal

Deciding whether to use this method depends entirely on your priorities and resources.

- If your primary focus is zero-cost processing for a very small batch: The wax floating method is a viable, traditional way to begin, provided you work in a low-humidity environment.

- If your primary focus is honey quality and efficiency: You must invest in a proper straining or filtration system to protect your honey from moisture contamination and save significant labor.

Ultimately, choosing the right purification method is the critical first step in preserving the quality and value of your harvest.

Summary Table:

| Aspect | Wax Floating Method |

|---|---|

| Principle | Gravity-based separation using density differences |

| Best For | Small-scale hobbyists or farmers with zero budget |

| Primary Risk | Moisture absorption, leading to fermentation |

| Key Drawback | Time-consuming, labor-intensive, and inefficient |

Ready to move beyond basic methods and protect your honey's quality? The wax floating method is a starting point, but commercial apiaries and distributors need efficient, reliable equipment to ensure product integrity and scale operations. HONESTBEE supplies professional-grade beekeeping supplies and equipment—like honey strainers and extractors—designed for wholesale-focused operations. Contact our experts today to find the right solutions for your commercial needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide

- What is the best way to melt beeswax for candles? The Safest Method for Professional Results

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs

- How does a steam wax melter work? A Fast, Efficient Method for High-Quality Wax