At its core, the manual honeycomb embossing machine is operated by hand, a design that emphasizes simplicity and direct user control over the process. Its operation is defined by a user-friendly mechanism that requires minimal setup, allowing a beekeeper to take a plain beeswax sheet and manually press a uniform honeycomb pattern onto it.

The true value of this machine lies not in speed, but in the control and self-sufficiency it provides. It empowers beekeepers to create their own custom foundation sheets with a durable, low-maintenance, and portable tool.

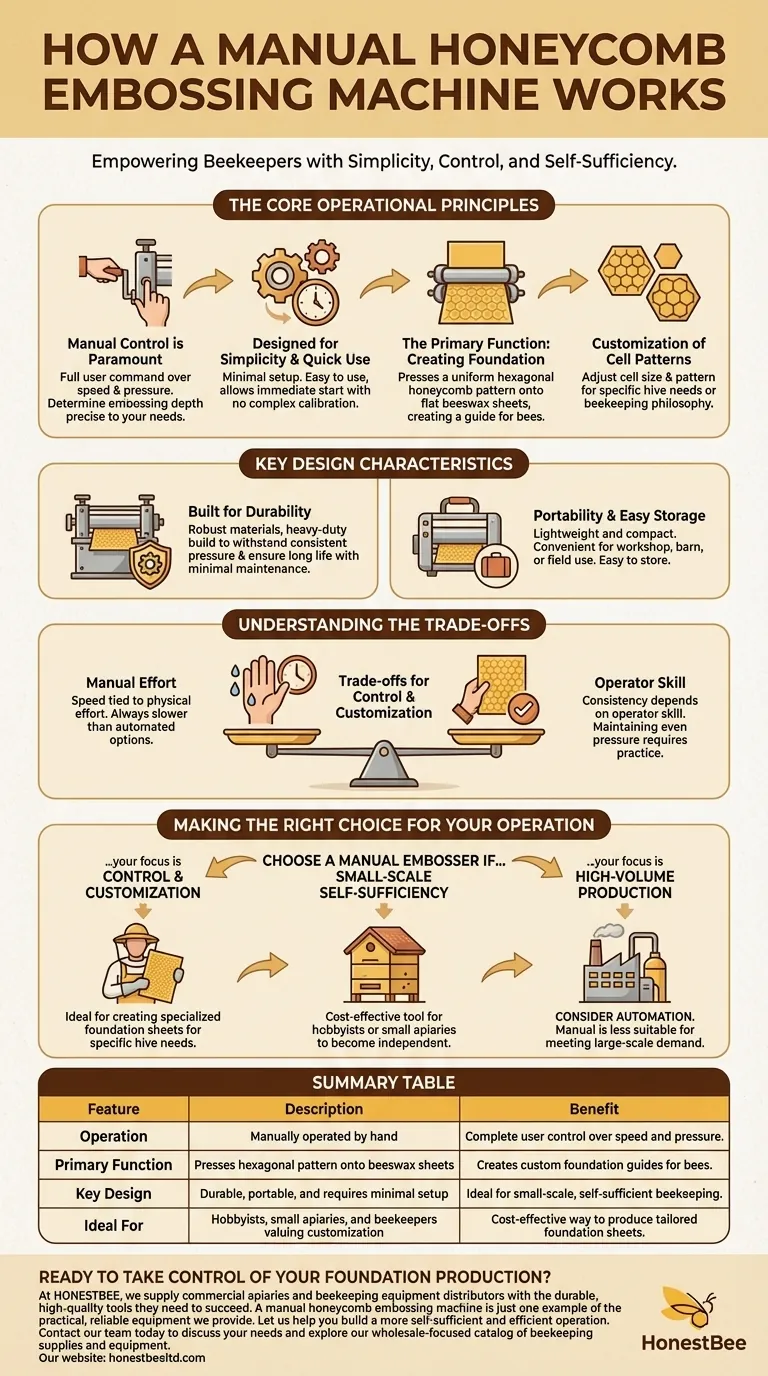

The Core Operational Principles

The machine's design is straightforward, centered on a few key functions that make it effective for small-to-medium-scale beekeeping operations.

Manual Control is Paramount

The term "manually operated" means you are in complete command. You control the speed and pressure applied to the beeswax, ensuring the embossing depth meets your specific requirements. This hands-on approach is a key feature, not a limitation.

Designed for Simplicity and Quick Use

Operation requires minimal setup. The machine is intentionally engineered to be easy to use, allowing beekeepers to quickly begin embossing sheets without a steep learning curve or complex calibration.

The Primary Function: Creating Foundation

The entire purpose of the machine is to press a perfect hexagonal honeycomb pattern onto a flat sheet of beeswax. This creates a "foundation" that gives bees a guide for building their comb, saving them time and energy.

Customization of Cell Patterns

A significant benefit of this manual process is the ability to customize the foundation. Beekeepers can adjust the cell size and pattern based on the specific needs of their hives or beekeeping philosophy.

Key Design Characteristics

The operational simplicity is supported by a design that prioritizes longevity and practicality in a typical beekeeping environment.

Built for Durability

These machines are constructed from robust, durable materials. This heavy-duty build is necessary to withstand the consistent pressure required for embossing and ensures the machine will deliver reliable performance for years with minimal maintenance.

Portability and Easy Storage

Most manual embossers are designed to be lightweight and compact. This portability is a major advantage, making it convenient to use the machine in a workshop, a barn, or any other location. Its small footprint also simplifies storage when not in use.

Understanding the Trade-offs

While effective, the manual nature of the machine presents clear trade-offs that are important to understand.

Manual Effort vs. Automated Speed

The primary trade-off is speed. A manual machine will always be slower than an electric or automated alternative. The output is directly tied to the physical effort you are willing and able to invest.

Operator Skill Determines Consistency

Unlike a fully automated system, the final quality and consistency of the embossed sheets depend on the operator. Maintaining even pressure and a steady hand is crucial for producing uniform results from one sheet to the next. This requires a small degree of practice to perfect.

Making the Right Choice for Your Operation

Choosing a manual embosser depends entirely on the scale and goals of your beekeeping.

- If your primary focus is control and customization: The manual machine is ideal for creating specialized foundation sheets tailored to your hives' specific needs.

- If your primary focus is small-scale self-sufficiency: This machine is a cost-effective tool for hobbyists or small apiaries wanting to become independent from commercial foundation suppliers.

- If your primary focus is high-volume production: An automated embossing machine would be a more suitable, albeit more expensive, investment to meet large-scale demand.

Ultimately, the manual honeycomb embossing machine places the power of foundation production directly into the beekeeper's hands.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Operation | Manually operated by hand | Complete user control over speed and pressure |

| Primary Function | Presses a hexagonal pattern onto beeswax sheets | Creates custom foundation guides for bees |

| Key Design | Durable, portable, and requires minimal setup | Ideal for small-scale, self-sufficient beekeeping |

| Ideal For | Hobbyists, small apiaries, and beekeepers valuing customization | Cost-effective way to produce tailored foundation sheets |

Ready to take control of your foundation production?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, high-quality tools they need to succeed. A manual honeycomb embossing machine is just one example of the practical, reliable equipment we provide.

Let us help you build a more self-sufficient and efficient operation. Contact our team today to discuss your needs and explore our wholesale-focused catalog of beekeeping supplies and equipment.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- How does the wax roller create wax foundation sheets? Boost Hive Efficiency with Uniform Comb Guides

- What is the economic potential of beeswax processing equipment? Unlock high-margin revenue for your apiary.

- What is the function of a manual tablet press machine in beekeeping? Create Pure Beeswax Foundation for Your Hives

- What is the specific function of a beeswax Casting Mold? Optimize Foundation for Improved Box Hives

- What is a fully automatic wax foundation machine and its purpose? Scale Your Beeswax Production with Precision

- What is the purpose of the hot water bath in the process of making wax foundation? Ensure Clean Release & Quality

- How do fully automatic wax foundation machines save time for beekeepers? Boost Your Apiary's Efficiency & Scale