For honey that is clear and ready for sale, the industry standard is to use a 200-micron filter. This size is fine enough to remove most visible impurities, such as small wax particles and other debris, while largely preserving the beneficial pollen that gives honey its unique character.

The ideal micron size for straining honey is a deliberate choice, not a single number. It is a balance between achieving a visually clear product (typically 200 microns) and preserving the maximum amount of natural pollen and character (often using 400-600 microns).

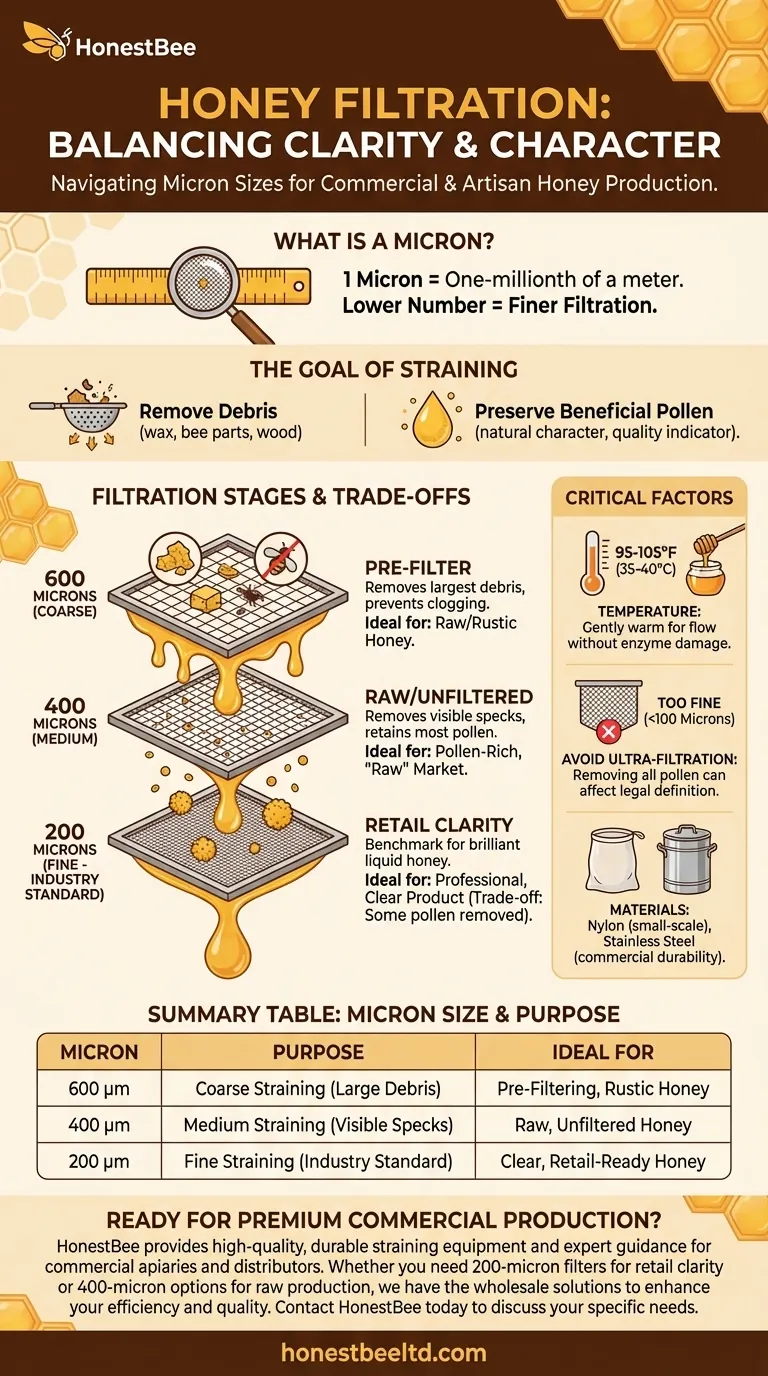

Why Micron Size is Critical for Honey

Understanding the purpose behind different filter sizes allows you to control the final quality and classification of your honey.

What "Microns" Measure

A micron is a unit of measurement equal to one-millionth of a meter. When discussing filters, it refers to the size of the holes in the mesh.

A lower micron number means smaller holes and therefore a finer level of filtration.

The Goal of Straining

Straining is intended to remove undesirable foreign matter that gets incorporated during the extraction process.

This includes bee parts, wax cappings, wood splinters from the hive bodies, and other large debris. The goal is a clean product, not a sterile one.

Preserving Natural Pollen

Pollen grains are a natural and beneficial component of honey. For many consumers, the presence of pollen is a key indicator of high-quality, unprocessed honey.

Most pollen grains range from 20 to 200 microns. A 200-micron filter is the cut-off point where some of the largest pollen grains or clumps of pollen may begin to be removed.

Common Straining Levels and Their Purpose

Beekeepers often use a multi-stage process, starting with a coarse filter and moving to a finer one.

600 Microns (Coarse Straining)

This is typically the first pass for freshly extracted honey. A 600-micron filter, often called a "pre-filter," is excellent for removing the largest pieces of debris like chunks of wax and stray bees.

This step is essential to prevent the finer filters from clogging too quickly. For many who prefer a very raw, rustic honey, this may be the only straining performed.

400 Microns (Medium Straining)

A 400-micron filter is a popular choice for beekeepers who want to market their product as "raw" or "unfiltered" but still present a clean product.

It removes nearly all visible specks while guaranteeing that the full spectrum of natural pollen is retained.

200 Microns (Fine Straining - The Standard)

This is the benchmark for clear, liquid honey intended for retail shelves. It produces a brilliant, professional-looking product free of the fine "cloudiness" that small wax particles can cause.

While it preserves most pollen, it can filter out larger grains, which is a trade-off for achieving maximum clarity.

Understanding the Trade-offs

The process of straining involves more than just the filter itself. Temperature and technique play crucial roles.

The Critical Role of Temperature

Honey is viscous, meaning it resists flowing. Cold honey will barely pass through a fine filter.

Gently warming honey to 95-105°F (35-40°C) dramatically lowers its viscosity, allowing it to flow easily through strainers without damaging its delicate enzymes and aromas. This can be done in a warming cabinet or with a jacketed tank.

The Pitfall of Going Too Fine

Using filters significantly finer than 200 microns (e.g., 100 microns or less) crosses the line from straining into ultra-filtration.

This process removes all pollen and other microscopic suspended solids. In many jurisdictions, honey that has been ultra-filtered cannot legally be sold as "honey" because the pollen, which is used to verify the honey's floral and geographic origin, has been removed.

Common Straining Materials

In small-scale operations, nylon filter bags are common as they are affordable, effective, and reusable. For larger processors, stainless steel filters are the standard due to their durability and ease of sanitization.

Making the Right Choice for Your Goal

Select your filtration level based on your desired final product and how you intend to market it.

- If your primary focus is producing crystal-clear honey for retail: Use a two-stage system, starting with a 600-micron pre-filter and finishing with a 200-micron filter for a professional appearance.

- If your primary focus is selling "raw" and pollen-rich honey: A single pass through a 400-micron filter provides a clean product while guaranteeing the preservation of all natural pollen.

- If your primary focus is personal use or minimal processing: A simple 600-micron filter is often sufficient to remove the largest particles, leaving the honey in its most natural state.

Ultimately, selecting the right filter empowers you to control the final character and presentation of your honey.

Summary Table:

| Micron Size | Purpose | Ideal For |

|---|---|---|

| 600 Microns | Coarse straining; removes large debris (wax, bees) | Pre-filtering, raw/rustic honey |

| 400 Microns | Medium straining; retains all pollen, removes visible specks | Raw, unfiltered honey |

| 200 Microns | Fine straining; industry standard for clear, retail-ready honey | Professional, clear liquid honey |

Ready to produce premium, professionally strained honey?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the high-quality straining equipment and expert guidance you need. Whether you require durable 200-micron filters for retail clarity or 400-micron options for raw honey production, we have the solutions to enhance your efficiency and product quality.

Contact HONESTBEE today to discuss your specific needs and explore our wholesale-focused product range. Let us help you achieve the perfect balance of clarity and natural goodness in every batch.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Professional Stainless Steel Honey Filter with Support Handle

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- What is better, a 100 or 200 micron filter? Find the Right Fit for Your Water System

- What are the functions and advantages of using honey strainers? Ensure Purity & Quality in Your Harvest

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality