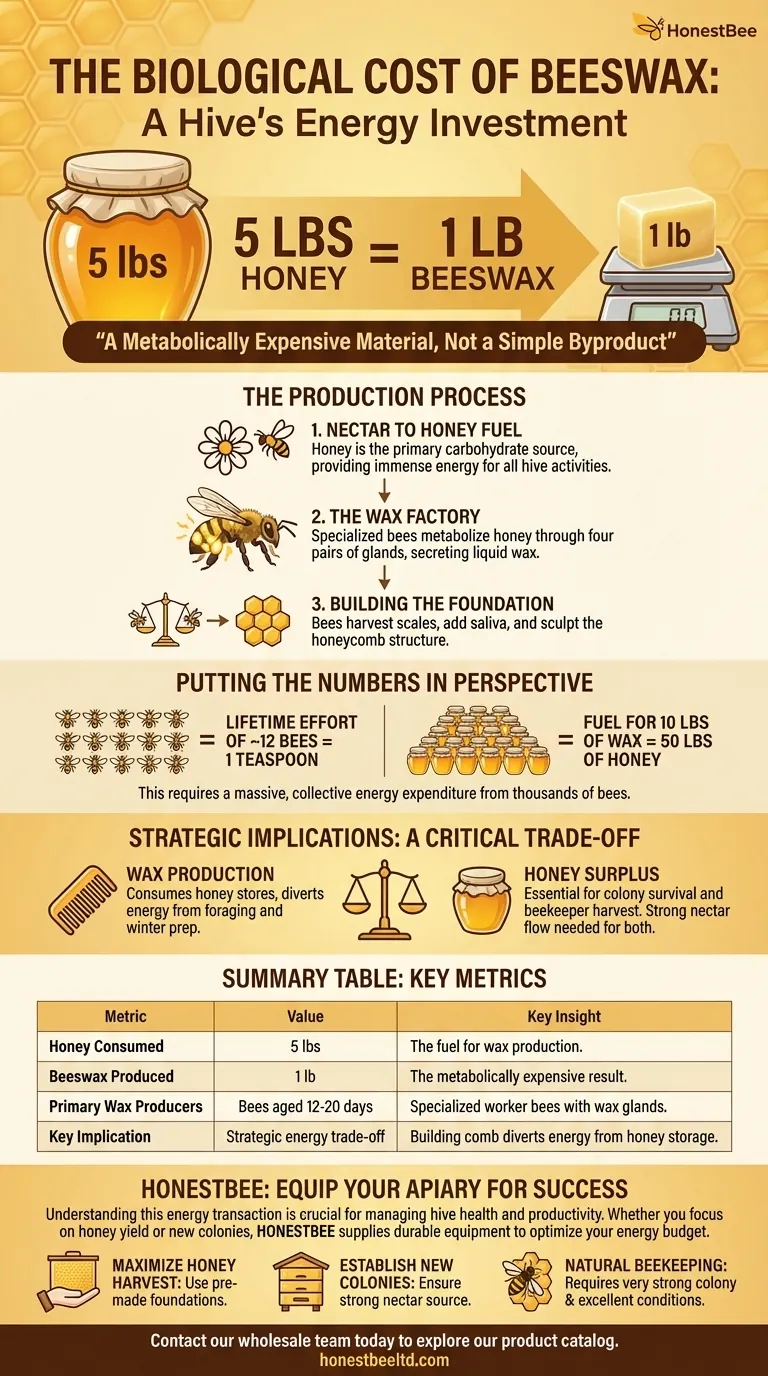

To produce one pound of beeswax, a colony of honey bees must consume approximately five pounds of honey. This significant energy investment highlights that beeswax is not a simple byproduct but a metabolically expensive and vital material for the hive's survival and structure.

The core principle to understand is that beeswax production represents a massive energy expenditure for a honey bee colony. The 5-to-1 honey-to-wax consumption ratio is a critical metric for appreciating hive health, resource management, and the true cost of building a home.

The Biological Cost of Wax Production

To grasp the significance of the honey-to-wax ratio, it's essential to understand the biological process behind it. Beeswax is a manufactured product, with honey serving as both the raw material and the fuel for the factory.

From Nectar to Fuel

Honey is the primary carbohydrate source for bees, providing the immense energy required for all hive activities, from flight to temperature regulation. Wax production is one of the most energy-intensive tasks a bee can perform.

The Anatomy of a Wax Factory

Specialized worker bees, typically between 12 and 20 days old, are the primary wax producers. They consume large quantities of honey, which their bodies metabolize through four pairs of specialized glands on the underside of their abdomens.

This process secretes liquid wax, which hardens into tiny, clear flakes or scales upon contact with the air.

Building the Hive's Foundation

Other worker bees then harvest these delicate wax scales. They chew and manipulate them, adding saliva to make them pliable, before meticulously shaping them into the iconic six-sided cells that form the honeycomb. This comb serves as the hive's nursery, pantry, and communication center.

Putting the Numbers in Perspective

The 5-to-1 ratio is impressive on its own, but its true scale becomes clear when you consider the effort required to produce the initial honey.

The Astonishing Effort for Honey

It takes the entire lifetime of approximately twelve bees to produce just one single teaspoon of honey. This fact provides a baseline for the incredible labor involved in creating the hive's food stores.

The Hive's Energy Budget

Now, consider the fuel for ten pounds of wax: fifty pounds of honey. This requires a staggering amount of collective effort from thousands of bees, each contributing their life's work. A colony must make a strategic decision to divert this massive energy reserve away from immediate survival and into infrastructure.

Understanding the Implications

For a honey bee colony, the decision to produce wax is a significant trade-off. This energy calculation has direct consequences for the hive's priorities and a beekeeper's management strategy.

Wax Production vs. Honey Surplus

When bees are focused on building new comb, they are consuming honey that would otherwise be stored for winter or harvested as surplus. A strong nectar flow is essential to support both comb construction and honey storage simultaneously.

The Strain on New Colonies

A newly established colony has a monumental task. It must build its entire honeycomb structure from scratch, consuming a vast portion of its initial foraged resources to create the very space it needs to store food and raise the next generation of bees.

How to Apply This to Your Goal

Understanding this fundamental energy transaction allows you to make more informed decisions, whether you are a beekeeper or simply an enthusiast.

- If your primary focus is maximizing honey harvest: Provide your bees with pre-made foundation or drawn comb to reduce their wax-building burden, allowing them to dedicate more energy to foraging and honey production.

- If your primary focus is establishing a new colony: Ensure the new hive has a strong and consistent source of nectar (or supplemental feed) to fuel the demanding process of drawing their initial comb.

- If your primary focus is natural, foundationless beekeeping: Recognize that this method requires a very strong colony and excellent foraging conditions to support the high metabolic cost of creating their entire comb structure naturally.

Knowing the true cost of beeswax transforms your understanding of the honey bee colony from a simple producer into a complex, self-regulating system managing a tight energy budget.

Summary Table:

| Metric | Value | Key Insight |

|---|---|---|

| Honey Consumed | 5 lbs | The fuel for wax production. |

| Beeswax Produced | 1 lb | The metabolically expensive result. |

| Primary Wax Producers | Bees aged 12-20 days | Specialized worker bees with wax glands. |

| Key Implication | Strategic energy trade-off | Building comb diverts energy from honey storage. |

Equip your apiary for success with HONESTBEE.

Understanding the immense energy bees invest in wax production is crucial for managing hive health and maximizing productivity. Whether you're a commercial apiary focused on honey yield or a distributor supplying beekeepers, having the right equipment is fundamental.

HONESTBEE supplies the durable beekeeping supplies and equipment—from foundations to full hive systems—that support strong colonies and efficient operations. Let us help you optimize your energy budget and achieve your beekeeping goals.

Contact our wholesale team today to discuss your needs and explore our product catalog.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What is the function of patterned wax foundation in experimental honeycomb? Achieve Research Precision

- What are the advantages of using beeswax foundation in a beehive? Boost Honey Yields and Hive Purity

- What is the primary function of drone comb foundations in controlled honeybee breeding? Unlock Genetic Precision

- What is the function of wax comb foundations? Boost Efficiency and Purity in Commercial Comb Honey Production

- What is done with the beeswax cappings after they are removed? Turn Your Hive Byproducts into Gold

- What are the primary commercial applications for rendered beeswax cappings? Maximize Your Apiary's Profitability

- Why is a combination of full wax foundation and partial frames used? Balancing Bee Instincts with Hive Management

- Why install beeswax foundation in petri dishes for Varroa mite grooming? Optimize Behavioral Research Authenticity