To properly evaluate a honey processing plant, you must assess its capacity to handle your volume and the efficiency of its entire operation. This involves scrutinizing its equipment, verifying quality certifications, and considering logistical factors like location, which directly impact your supply chain and final product quality.

True efficiency in honey processing is not just about speed. It is the plant's ability to consistently produce high-quality, safe honey at a predictable cost while integrating seamlessly into your specific supply chain.

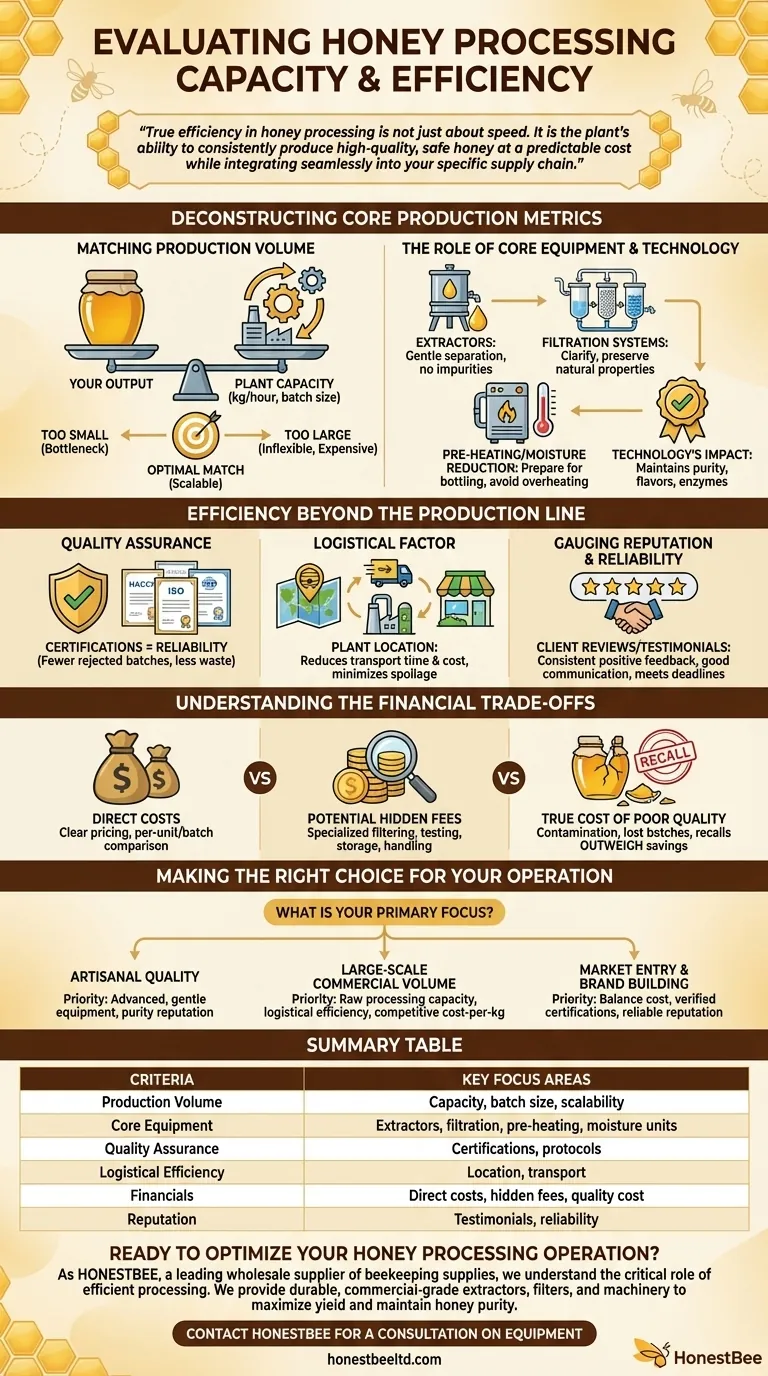

Deconstructing Core Production Metrics

The most visible measures of a plant are its physical capacity and the technology it employs. These factors determine the volume, speed, and quality of the final product.

Matching Production Volume

A plant's stated processing capacity is the first checkpoint. You need to ensure it can handle your current and projected honey output, whether measured in kilograms per hour or total batch size.

A mismatch here creates significant risk. A plant that is too small will become a bottleneck, while a plant that is too large may be inflexible or too expensive for smaller producers.

The Role of Core Equipment

State-of-the-art equipment is a direct indicator of both efficiency and quality control. Key systems include reception, straining, pre-heating, filtration, moisture reduction, and pasteurization units.

Look for high-quality extractors that separate honey from the comb without introducing impurities and advanced filtration systems that clarify the honey while preserving its natural properties.

Technology's Impact on Honey Purity

Modern processing technology is designed to maintain the integrity of the honey. Efficient pre-heating and moisture reduction systems, for example, can prepare the honey for bottling without overheating it, which can degrade its delicate flavors and beneficial enzymes.

Efficiency Beyond the Production Line

A plant's operational efficiency extends far beyond its machinery. The systems for quality, logistics, and client management are equally critical for a successful partnership.

Quality Assurance as a Predictor of Reliability

Look for quality certifications from recognized food safety authorities. These are not just paperwork; they prove the plant adheres to strict standards for safety and handling.

A plant with robust quality assurance protocols will have fewer rejected batches, less waste, and more predictable outcomes, which is the foundation of operational efficiency.

The Logistical Factor

The plant's location is a crucial efficiency variable. A strategically located facility reduces transportation time and costs, minimizes the risk of spoilage, and streamlines distribution to your end markets.

Consider its proximity to your apiaries and your customers to create the most efficient supply chain possible.

Gauging Reputation and Reliability

Finally, research the plant's reputation through client reviews and testimonials. Consistent positive feedback is a strong indicator of reliability, good communication, and the ability to meet deadlines—all hallmarks of an efficient and trustworthy partner.

Understanding the Financial Trade-offs

A comprehensive evaluation must balance operational capability with financial viability. The cheapest option is rarely the most efficient in the long run.

Comparing Direct Costs

Obtain clear pricing structures from any potential partner. Compare the costs on a per-unit or per-batch basis to understand the direct impact on your margins.

Uncovering Potential Hidden Fees

Ask directly about any potential hidden fees. These can include charges for specialized filtering, batch testing, storage, or handling, which can significantly alter the total cost.

The True Cost of Poor Quality

An inefficient plant with outdated equipment or poor quality control can lead to contaminated or damaged honey. The cost of a lost batch or a product recall will always outweigh any initial savings on processing fees.

Making the Right Choice for Your Operation

The ideal plant depends entirely on your specific goals. Use these criteria to weigh your options based on what matters most to your business.

- If your primary focus is artisanal quality: Prioritize a plant with advanced, gentle equipment and a strong reputation for maintaining honey purity, even if the capacity is lower.

- If your primary focus is large-scale commercial volume: Emphasize raw processing capacity, logistical efficiency (location), and a competitive cost-per-kilogram.

- If your primary focus is market entry and brand building: Balance cost with verified quality certifications and a reliable reputation to ensure a consistent, safe, and credible product.

Ultimately, choosing the right processing partner is a strategic decision that directly shapes your product's quality and your business's profitability.

Summary Table:

| Evaluation Criteria | Key Focus Areas |

|---|---|

| Production Volume | Processing capacity (kg/hour), batch size, scalability |

| Core Equipment | Extractors, filtration systems, pre-heating, moisture reduction units |

| Quality Assurance | Food safety certifications (e.g., HACCP, ISO), quality control protocols |

| Logistical Efficiency | Plant location, proximity to apiaries/customers, transportation costs |

| Financials | Direct costs per unit, potential hidden fees, cost of poor quality |

| Reputation | Client testimonials, reliability, communication, on-time delivery |

Ready to Optimize Your Honey Processing Operation?

As HONESTBEE, a leading wholesale supplier of beekeeping supplies and equipment to commercial apiaries and distributors, we understand the critical role that efficient processing plays in your profitability. The right equipment is the foundation of a high-capacity, high-quality honey processing plant.

We can provide the durable, commercial-grade extractors, filters, and other essential machinery you need to build or upgrade a facility that maximizes yield and maintains honey purity. Let's discuss how our solutions can help you achieve a more efficient and reliable supply chain.

Contact HONESTBEE today for a consultation on equipment tailored to your commercial scale.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the primary function of industrial filling equipment? Maximize Honey Profitability and Market Access

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency

- What role do honey filling machines play in meeting quality standards? Ensure Global Export Compliance

- What is the significance of automated honey-filling machines? Scale Your Apiary with Precision and Efficiency