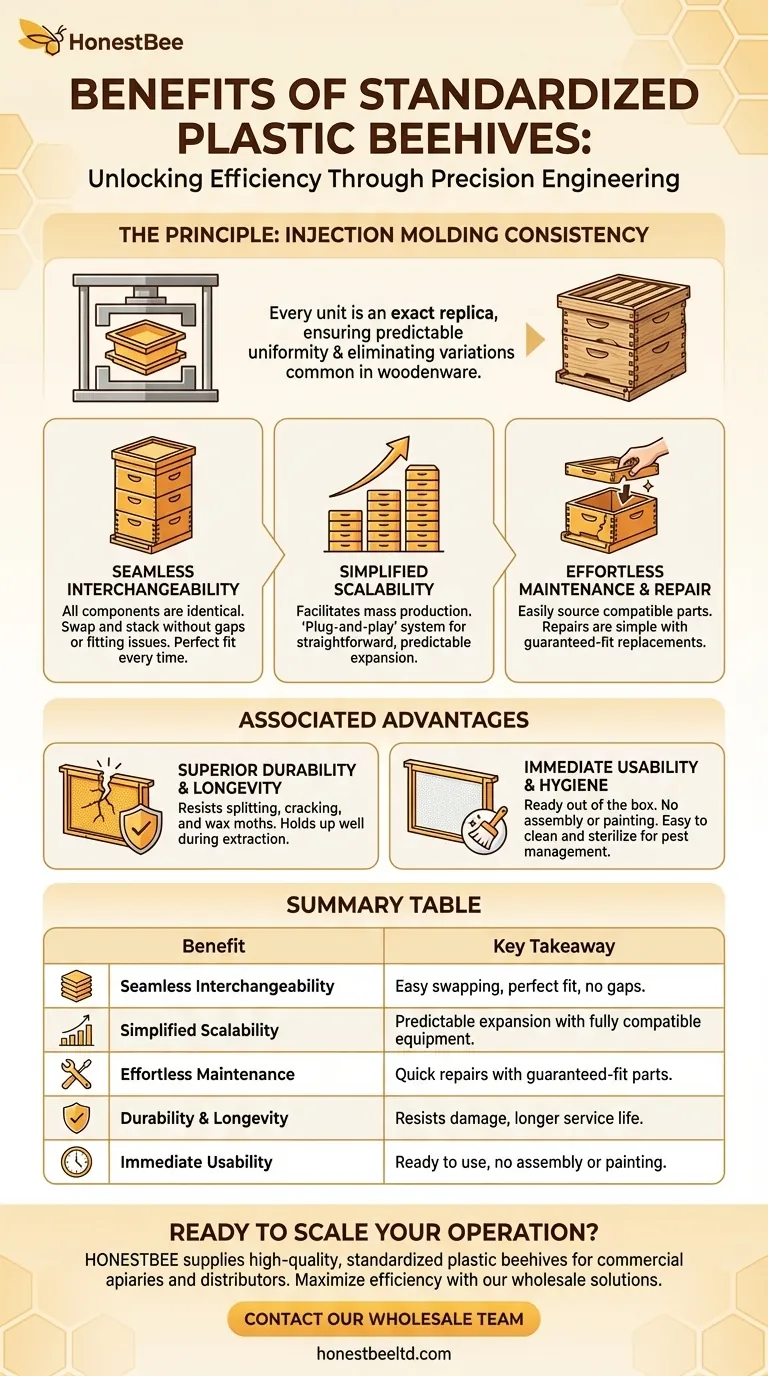

The primary benefit of the standardized specifications of plastic beehives is the perfect, predictable uniformity of every component. Because they are created from a single mold, every box, frame, and accessory is identical, which ensures seamless interchangeability and simplifies nearly every aspect of hive management, from expansion to maintenance.

The core advantage is not the plastic itself, but the industrial precision it enables. This standardization transforms hive management from a craft requiring custom fitting into a predictable system of interchangeable parts, boosting efficiency and scalability.

The Principle of Manufacturing Consistency

The advantages of plastic hives stem directly from their manufacturing process. Unlike wood, which can have natural variations and requires precise cutting and assembly, plastic components are injection-molded.

The Impact of Molding

Molding ensures that every single unit produced is an exact replica of the last. This process eliminates the minor variations in dimension that can occur with woodenware from different suppliers or even within the same batch.

A Contrast with Traditional Materials

Wooden hives, while excellent, can sometimes have slight inconsistencies. A super from one manufacturer might not sit perfectly flush on a brood box from another, potentially creating gaps that can lead to drafts or entry points for pests. This requires beekeepers to be more hands-on with fitting and repairs.

Direct Benefits of Standardization

This manufacturing consistency translates into three critical operational advantages for the beekeeper.

Seamless Interchangeability

Because every component is identical, parts can be swapped and combined without a second thought. You can stack supers, move frames between boxes, and replace lids or bottom boards with the confidence that everything will fit perfectly every time.

Simplified Scalability

Standardization facilitates mass production, making it easy to expand your apiary. Ordering new equipment is straightforward, as you know the new boxes will be fully compatible with your existing hives. This creates a simple, "plug-and-play" system for growth.

Effortless Maintenance and Repair

When a component is damaged, finding a replacement is simple. You can easily source compatible accessories and parts for repairs or upgrades, knowing they will fit without modification. This reduces the time and effort spent on equipment upkeep.

Associated Advantages of Plastic Construction

While standardization is key, the material itself offers several related benefits that enhance hive management.

Superior Durability and Longevity

Plastic is extremely durable, resisting the splitting, cracking, and warping that can affect wood over time. It holds up exceptionally well during honey extraction and is not susceptible to damage from wax moths.

Integrated Pest Management

The non-porous surface of plastic makes it easy to clean and sterilize, which can help manage disease. Some beekeepers also find that black plastic frames make it much easier to spot the tiny, white queen eggs during hive inspections.

Immediate Usability

Most plastic hives and frames come ready to use right out of the box. There is no need for the time-consuming assembly, painting, or weatherproofing that is required for new woodenware.

Understanding the Trade-offs

While the benefits are significant, it is important to consider the complete picture. Plastic hives behave differently than traditional wooden hives, and these differences require consideration.

Insulation and Ventilation

Wood is a natural insulator, providing a buffer against extreme temperature swings. Plastic has different thermal properties, which may require beekeepers to adjust their strategies for wintering and managing ventilation to control internal moisture.

Bee Adaptation and Propolis

Bees have evolved for millennia in wooden cavities. While most colonies adapt well to plastic, they are unable to propolize and modify the interior surfaces in the same way they do with wood. This can change some internal hive dynamics.

Making the Right Choice for Your Goal

Ultimately, the choice between plastic and wood depends on your beekeeping philosophy and operational goals.

- If your primary focus is efficiency, scalability, and minimal maintenance: The standardized, durable, and ready-to-use nature of plastic hives is an outstanding choice.

- If your primary focus is traditional methods and natural materials: The breathability, insulation, and classic feel of wooden hives will be a better fit for your approach.

Choosing your equipment is about aligning the material's properties with the way you want to manage your bees.

Summary Table:

| Benefit | Key Takeaway |

|---|---|

| Seamless Interchangeability | All components are identical, allowing for easy swapping and stacking without gaps. |

| Simplified Scalability | Enables easy, predictable expansion of your apiary with fully compatible equipment. |

| Effortless Maintenance | Damaged parts are easily and quickly replaced with guaranteed-fit components. |

| Durability & Longevity | Resists splitting, warping, and wax moth damage, ensuring a longer service life. |

| Immediate Usability | Ready to use out of the box, eliminating time-consuming assembly and painting. |

Ready to scale your beekeeping operation with precision-engineered equipment?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-quality, standardized plastic beehives through our wholesale-focused operations. Our products are designed to deliver the uniformity and durability you need to maximize efficiency and simplify hive management.

Contact our wholesale team today to discuss your apiary's needs and discover how our supplies can help you grow.

Visual Guide

Related Products

- Beehive Entrance Discs Plastic Bee Entrance Disc for Bee Hives

- Professional Grade Foldable Beehive Handles

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Yellow Plastic Bucket Pail Perch for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What is the technical significance of monitoring honeybee traffic? Master Colony Efficiency with Data-Driven Beekeeping

- What is required to be a beekeeper? Essential Equipment, Knowledge & Mindset

- What factors influence the ideal winter entrance configuration for a beehive? Optimize Your Hive for Winter Survival

- What is the function of mouse guards in winter beehive management? Secure Your Colony with Proper Entrance Protection

- What does a fully closed setting on a round beehive entrance disc indicate? A Guide to Hive Security