At its core, a semi-automatic honey stick machine is a hybrid system that bridges the gap between manual labor and full automation. It automates the core packaging tasks of forming, filling, and sealing, but still requires a human operator for key steps like loading raw materials and removing the finished products.

The central characteristic to understand is the balance it strikes: a semi-automatic machine offers a significant increase in production over manual methods while keeping the initial investment and operational complexity lower than a fully automated system.

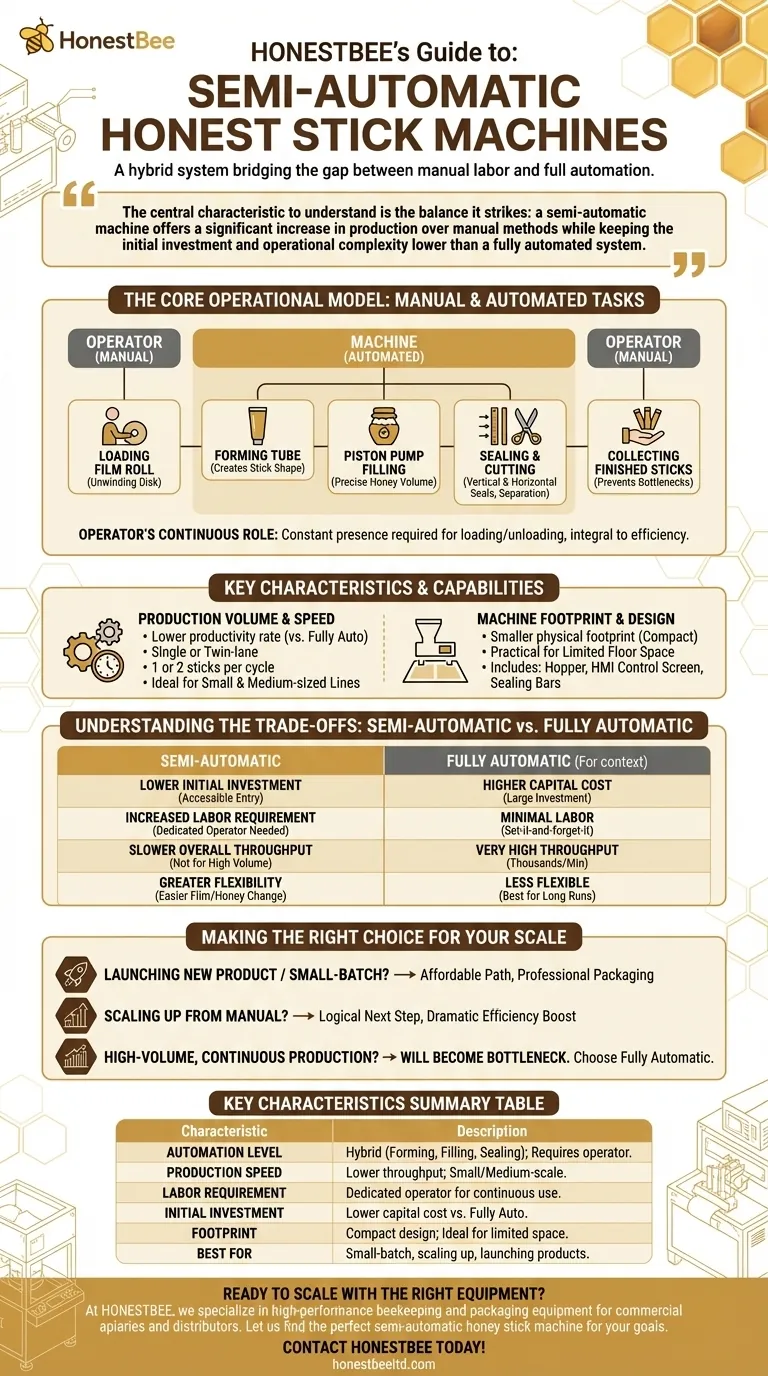

The Core Operational Model: Manual and Automated Tasks

A semi-automatic machine's workflow is defined by the specific tasks handled by the operator versus the machine itself. This division of labor is its most fundamental trait.

Manual Intervention Points

The term "semi-automatic" directly refers to the required manual touchpoints. An operator is responsible for loading the film roll onto the unwinding disk at the start of a run.

Critically, the operator must also manually collect the finished honey sticks as they are produced and exit the machine. This step prevents bottlenecks and keeps the process flowing.

The Automated Core Process

Once the film is loaded, the machine takes over the central packaging sequence. This includes automatically pulling the film, using a forming tube to create the stick shape, and vertically sealing the seam.

A piston pump then precisely fills the tube with a set volume of honey from the hopper. Finally, horizontal sealing bars seal both ends and a cutter separates the finished stick.

The Operator's Continuous Role

Unlike a "set it and forget it" fully automatic system, a semi-automatic machine requires the constant presence of an operator. Their role is integral to the machine’s continuous operation, making labor a key factor in its overall efficiency.

Key Characteristics and Capabilities

Understanding the operational model helps clarify the machine's inherent capabilities and limitations, which are crucial for determining if it fits your production needs.

Production Volume and Speed

These machines have a lower productivity rate compared to their fully automatic counterparts. They are typically single-lane or twin-lane, producing one or two sticks per cycle.

This output is perfectly suited for small and medium-sized packaging lines that are scaling up from manual methods but do not yet have the demand to justify a high-speed, multi-lane system.

Machine Footprint and Design

Generally, semi-automatic machines have a smaller physical footprint than large, multi-lane automatic models. This makes them a practical choice for facilities with limited floor space.

The design still includes essential components like a hopper, HMI touch screen for control, and sealing bars, but in a more compact and accessible configuration.

Understanding the Trade-offs: Semi-Automatic vs. Fully Automatic

Choosing this type of machine involves a clear set of trade-offs between cost, speed, and labor. Being aware of these is essential for making an informed investment.

Lower Initial Investment

The most significant advantage is a lower capital cost. Semi-automatic machines are more affordable to purchase than fully automated systems, making them an accessible entry point for growing businesses.

Increased Labor Requirement

The primary trade-off is the reliance on manual labor. The cost of a dedicated operator for loading and unloading must be factored into the total cost of ownership and operational planning.

Slower Overall Throughput

While much faster than packaging by hand, a semi-automatic machine cannot match the output of a fully automatic, multi-lane machine, which can produce thousands of sticks per minute. This makes it unsuitable for large-scale commercial operations where volume is the top priority.

Greater Flexibility for Small Batches

The manual touchpoints can offer an advantage in flexibility. It is often quicker and easier to change film rolls or switch between different honey types for smaller, more specialized production runs.

Making the Right Choice for Your Scale

Ultimately, the decision rests on a clear assessment of your production volume, labor availability, and business goals.

- If your primary focus is launching a new product or small-batch production: A semi-automatic machine provides an affordable path to professional packaging without a prohibitive upfront cost.

- If your primary focus is scaling up from manual methods: This machine is the logical next step, offering a dramatic boost in efficiency and consistency for a medium-sized business.

- If your primary focus is high-volume, continuous production: A semi-automatic machine will quickly become a bottleneck; you should invest in a fully automatic, multi-lane system.

Choosing the right equipment is about precisely matching the machine's capabilities to your operational reality and strategic ambitions.

Summary Table:

| Characteristic | Description |

|---|---|

| Automation Level | Hybrid system; automates forming, filling, sealing. Requires operator for loading/unloading. |

| Production Speed | Lower throughput than fully automatic machines; suitable for small/medium-scale operations. |

| Labor Requirement | Requires a dedicated operator for continuous operation. |

| Initial Investment | Lower capital cost compared to fully automatic systems. |

| Footprint | Compact design, ideal for facilities with limited space. |

| Best For | Small-batch production, scaling up from manual methods, or launching new products. |

Ready to Scale Your Honey Packaging with the Right Equipment?

Choosing the correct machine is critical for your operation's efficiency and growth. At HONESTBEE, we specialize in supplying durable, high-performance beekeeping and packaging equipment to commercial apiaries and distributors through our wholesale-focused operations.

Let us help you find the perfect semi-automatic honey stick machine to match your production volume and business goals. Our experts can guide you to a solution that balances cost, speed, and labor for optimal results.

Contact HONESTBEE today to discuss your needs and discover how our equipment can enhance your packaging line's productivity and profitability.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Premium Heat-Resistant Glass Honey Dipper

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

People Also Ask

- How can honey filling and metering equipment evaluate legume supplement effectiveness? Quantify Your ROI Precisely

- When is a pump filling machine the ideal choice for filling honey? Boost Efficiency and Scalability for Your Apiary

- How does a piston honey filler work? Master Precision Filling for Viscous Honey and Commercial Jars

- Why are automated filling and sealing machines critical? Scale Your Honey Business for Global Retail and Export Success

- How do automated honey filling machines ensure product quality and safety? Optimize Your Packaging Standards

- What technical challenges do automatic filling machines address? Master Honey Packaging with Precision & Hygiene

- What advantages do industrial semi-automatic filling machines offer? Scale Your Honey Production and Consistency

- What is the function of bottling equipment in honey processing? Ensure Quality and Commercial Precision