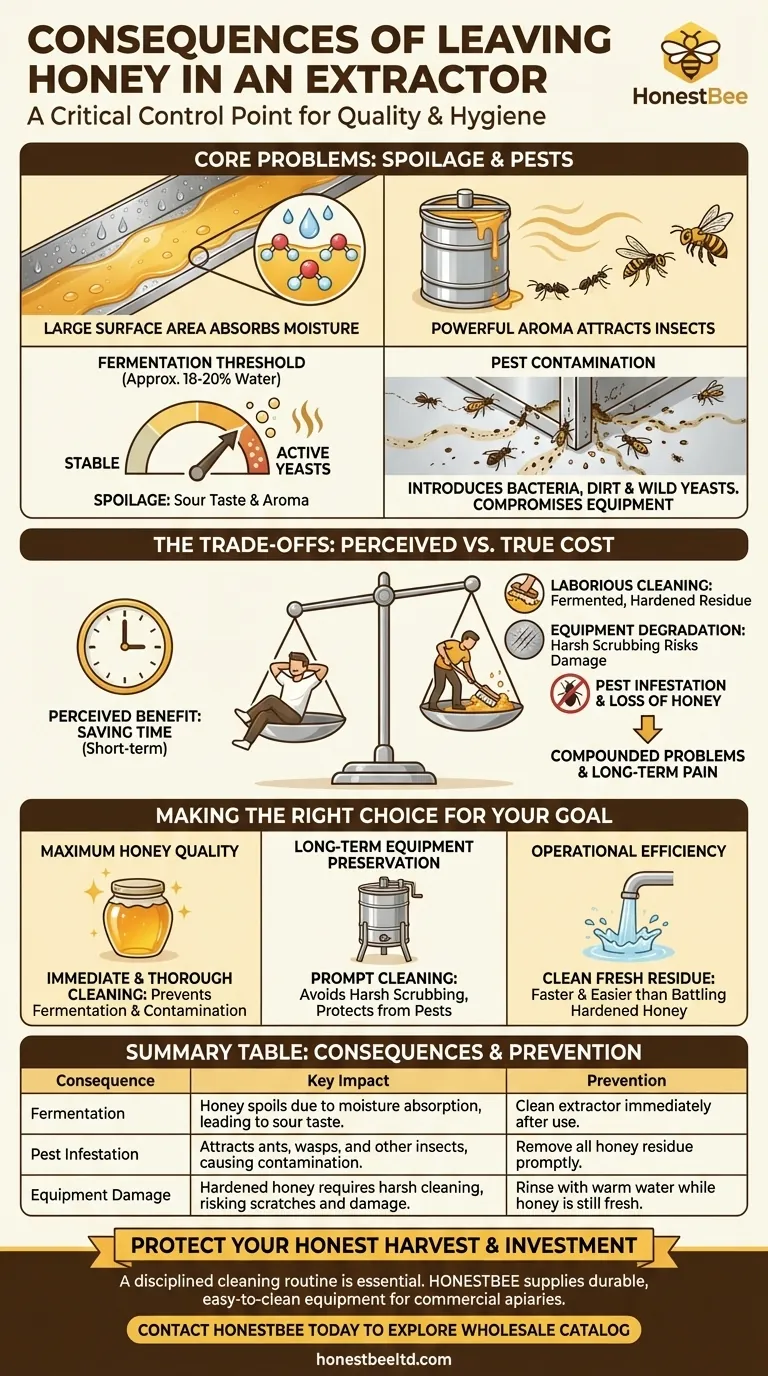

At its core, leaving honey in an extractor invites two significant problems: spoilage and pests. The thin layer of honey left behind has a large surface area, allowing it to rapidly absorb moisture from the air, which can lead to fermentation. At the same time, its powerful aroma acts as an open invitation for ants, wasps, and other insects, compromising the hygiene of your equipment.

The decision to clean your extractor immediately after use is not merely about tidiness. It is a critical control point for preserving the quality of your honey and ensuring the long-term integrity and hygiene of your processing equipment.

The Science of Honey Spoilage

Understanding why leftover honey is a problem requires looking at its unique chemical properties. Honey's longevity is not guaranteed; it depends on maintaining its low water content.

Honey's Hygroscopic Nature

Honey is hygroscopic, meaning it actively draws in and holds water molecules from the surrounding atmosphere. A sealed jar of honey is stable, but a thin film of honey coating the inside of an extractor is in a highly vulnerable state.

This exposed layer will continuously absorb moisture, especially in humid conditions. This process systematically dilutes the honey, changing its chemical balance.

The Fermentation Threshold

Raw honey contains natural, dormant yeasts. These yeasts remain inactive as long as the honey's water content stays below approximately 18-20%.

When the leftover honey absorbs enough atmospheric moisture to cross this threshold, the yeasts activate. They begin to consume the honey's sugars, producing alcohol and carbon dioxide. This is fermentation, which spoils the honey, giving it a sour, undesirable taste and aroma.

The Inevitable Pest Problem

Beyond spoilage, a honey-coated extractor is a powerful beacon for a wide range of pests. This creates immediate contamination risks and long-term infestation problems.

A Powerful Attractant

The scent of honey can be detected by insects from a remarkable distance. Leaving an uncleaned extractor, even for a day or two, is enough to attract ants, wasps, yellow jackets, and honey bees from other colonies.

These insects will not only consume the leftover honey but will establish scent trails leading others back to the source, potentially creating a persistent nuisance around your processing area.

The Risk of Contamination

Pests introduce foreign contaminants into your equipment. This includes bacteria, wild yeasts, dirt, and insect parts.

This contamination is not just on the surface. It can work its way into the seams and moving parts of your extractor, making a future, thorough cleaning far more difficult and compromising the purity of your next honey harvest.

Understanding the Trade-offs

The temptation to delay cleaning is understandable, as it's often the last, tiring step of a long extraction day. However, the perceived benefit is an illusion that carries significant costs.

The Perceived "Benefit": Saving Time

The only reason to leave honey in an extractor is to postpone the task of cleaning it. This seems like an efficient choice in the moment, allowing you to move on to other tasks.

The True Cost: Compounded Problems

This short-term time saving leads to long-term pain. Fermented, hardened honey is significantly more difficult to clean than fresh, liquid honey. What would have been a simple warm-water rinse becomes a laborious scrubbing session.

Furthermore, any honey you hoped to recover is now likely spoiled. A pest infestation can require extensive cleaning and even pest control measures, completely negating any time saved initially.

Equipment Degradation

Aggressive cleaning required to remove hardened, sticky residue can damage your extractor. Harsh scrubbing can scratch stainless steel surfaces, creating micro-crevices where bacteria can hide. For plastic or non-stainless models, the risk of damage is even higher.

Making the Right Choice for Your Goal

Your approach to extractor maintenance directly reflects your goals as a beekeeper. Choose the practice that aligns with your desired outcome.

- If your primary focus is maximum honey quality: Immediate and thorough cleaning after every use is the only acceptable practice to prevent fermentation and contamination.

- If your primary focus is long-term equipment preservation: Prompt cleaning prevents the need for harsh scrubbing and protects your extractor from pests, ensuring it remains a reliable tool for years.

- If your primary focus is operational efficiency: Cleaning fresh honey residue with warm water is far faster and easier than battling hardened, fermented honey and pest infestations later.

Ultimately, treating your equipment with disciplined hygiene is a fundamental aspect of producing high-quality honey.

Summary Table:

| Consequence | Key Impact | Prevention |

|---|---|---|

| Fermentation | Honey spoils due to moisture absorption, leading to sour taste. | Clean extractor immediately after use. |

| Pest Infestation | Attracts ants, wasps, and other insects, causing contamination. | Remove all honey residue promptly. |

| Equipment Damage | Hardened honey requires harsh cleaning, risking scratches and damage. | Rinse with warm water while honey is still fresh. |

Protect your honey harvest and investment in your apiary. A disciplined cleaning routine is essential for producing high-quality honey and preserving your equipment. At HONESTBEE, we supply durable, easy-to-clean beekeeping supplies and extraction equipment designed for the rigorous demands of commercial apiaries and distributors. Let us help you build a more efficient and hygienic operation.

Contact HONESTBEE today to explore our wholesale-focused catalog and find the right equipment for your needs.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- How long does honey take to extract? A Guide to Streamlining Your Harvest Process

- How does a mechanical brake unit contribute to the safety and operation of a honey extractor? Enhance Safety and Speed

- What factors should be considered when choosing an electric honey extractor? A Guide for Beekeepers

- What technical specifications should be considered for honey extraction equipment? Expert Guide to Choosing the Best Tools

- What are the advantages of industrial honey extractors? Boost Yield and Purity for Commercial Success

- What role does specialized honey extraction equipment play in the post-harvest honey processing stage? Boost Yield & Quality

- What is the operating mechanism of a Centrifugal Honey Extractor? Boost Apiary Yield through Physics

- How is the honey extracted from the uncapped frames? A Guide to Efficient & Gentle Harvesting