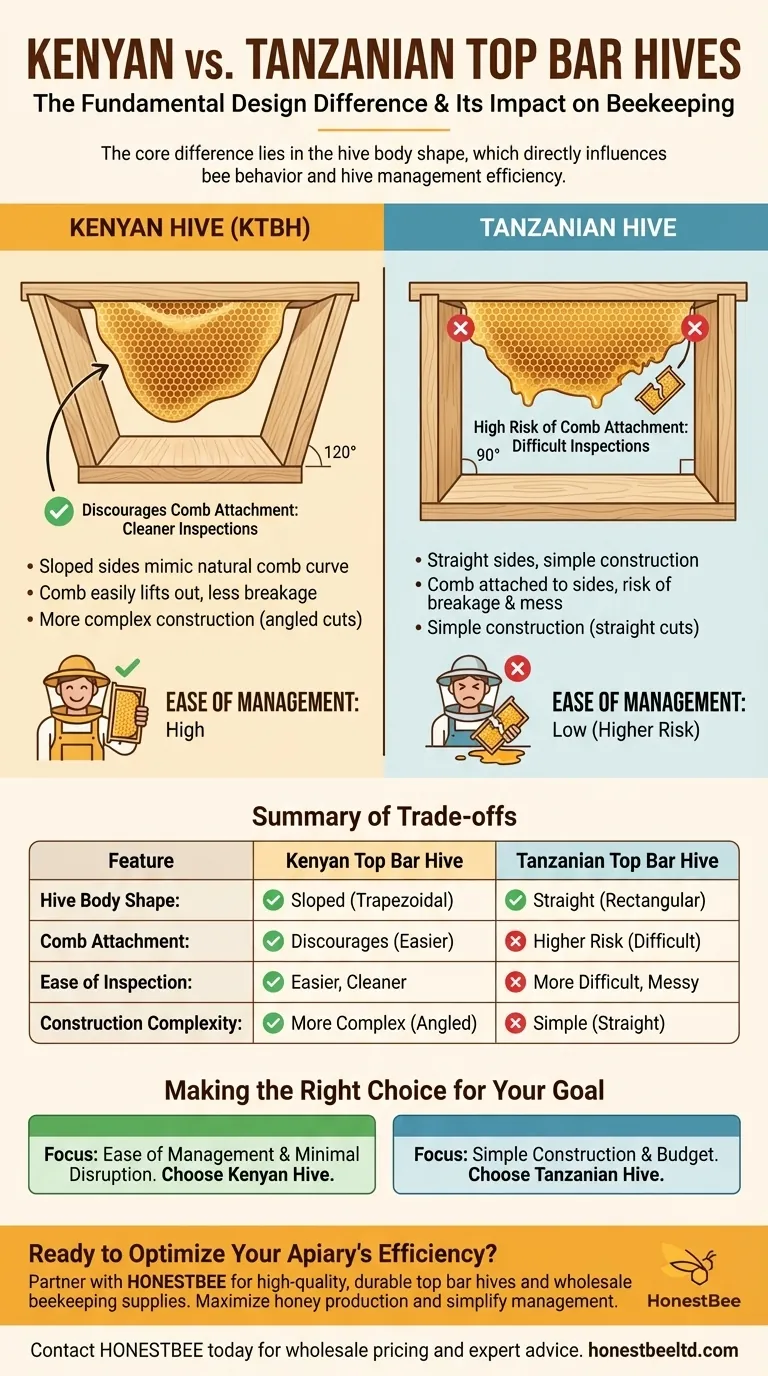

The fundamental difference between Kenyan and Tanzanian top bar hives lies in the shape of the hive body. A Kenyan top bar hive (KTBH) has sides that are sloped inwards from top to bottom, creating a trapezoidal shape. In contrast, the Tanzanian top bar hive features straight, vertical sides, forming a simple rectangular box. This single design variation directly influences how bees build their comb and how the beekeeper manages the hive.

While both are effective horizontal hives, the Kenyan design's sloped walls actively discourage bees from attaching comb to the sides, making inspections significantly easier. The Tanzanian design prioritizes construction simplicity at the cost of potentially more difficult comb management.

The Core Design Distinction

The choice between a Kenyan and Tanzanian hive comes down to a single geometric principle that has a cascading effect on the entire beekeeping experience.

Kenyan Hive: The Sloped-Side Design

The sides of a Kenyan hive are angled, typically forming a 120-degree angle with the bottom board. This specific shape is not arbitrary.

It is designed to mimic the natural catenary curve of a freely hanging honeycomb. This makes the design more "bee-centric" by providing a shape that bees are naturally inclined to build within without attachment.

Tanzanian Hive: The Straight-Side Design

The Tanzanian hive is a straightforward rectangular trough. Its sides are set at a 90-degree angle to the bottom board.

This design is simpler from a woodworking perspective, as it requires only straight cuts. It offers a slightly larger internal volume compared to a KTBH of the same width and height.

How Hive Shape Impacts Bee Behavior

A beekeeper's primary interaction with the hive is inspecting and removing combs. The hive's internal geometry is the most important factor determining how easy or difficult this process will be.

Comb Attachment

This is the most critical implication of the design difference. As bees build their comb downwards from the top bar, the sloped walls of the Kenyan hive naturally recede from the comb's edge.

This separation discourages the bees from "gluing" the comb to the hive walls. Combs can be lifted straight out for inspection without breaking.

In a Tanzanian hive, the vertical walls remain a constant distance from the comb, increasing the likelihood that bees will attach the comb directly to the sides, especially as it gets larger.

The Management Consequence

When a comb is attached to the side walls, it cannot be lifted out cleanly. The beekeeper must use a hive tool to sever the connection before removing the bar.

This action can break the delicate comb, spill honey, and significantly agitate the colony. It makes inspections slower, messier, and more disruptive for the bees.

Understanding the Trade-offs

Neither design is inherently "bad," but they prioritize different goals. Understanding the trade-offs is key to making an informed decision.

Kenyan Hive: Clean Inspections, More Complex Build

The primary advantage is ease of management. The reduced side attachment leads to cleaner, faster, and less stressful inspections for both the bees and the beekeeper.

The main trade-off is that it is slightly more complex to build due to the need for angled cuts.

Tanzanian Hive: Simple Build, Higher Management Risk

The primary advantage is the simplicity of construction. Anyone with basic woodworking skills can build a rectangular box.

The trade-off is a higher risk of difficult inspections. The beekeeper must be prepared to carefully manage combs that are attached to the walls, which requires more skill and patience.

Making the Right Choice for Your Goal

Your beekeeping philosophy and practical constraints should guide your choice.

- If your primary focus is ease of management and minimal hive disruption: The Kenyan hive is the superior choice due to its design that discourages side-attached comb.

- If your primary focus is simplicity of construction and you are on a tight budget: The Tanzanian hive is easier and potentially cheaper to build, but be prepared for more challenging inspections.

Ultimately, selecting the right hive comes down to understanding how its internal geometry influences the natural behavior of your bees.

Summary Table:

| Feature | Kenyan Top Bar Hive | Tanzanian Top Bar Hive |

|---|---|---|

| Hive Body Shape | Sloped sides (trapezoidal) | Straight, vertical sides (rectangular) |

| Comb Attachment | Discourages side attachment | Higher risk of side attachment |

| Ease of Inspection | Easier, cleaner comb removal | More difficult, can be messy |

| Construction Complexity | More complex (angled cuts) | Simple (straight cuts) |

Ready to Optimize Your Apiary's Efficiency?

Choosing the right hive is crucial for successful, sustainable beekeeping. Whether you manage a commercial apiary or are a distributor of beekeeping equipment, HONESTBEE is your trusted partner. We supply high-quality, durable top bar hives and a full range of beekeeping supplies through our wholesale-focused operations.

Let us help you select the perfect equipment to maximize your honey production and simplify hive management. Contact HONESTBEE today for wholesale pricing and expert advice tailored to your operation's needs.

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- Why are hive inspections easier with Top Bar Hives? Achieve a Calmer, Safer Approach to Beekeeping

- How is honey harvested from a top-bar hive? A Guide to Simple, Low-Equipment Processing

- How do bees behave differently in Top Bar vs. Langstroth hives? Understand the Architectural Impact

- What is the quickest method to harvest honey from a top bar hive? A Guide to the Simple 'Cut and Crush' Method

- How is honey harvested from top-bar hives? Master the Crush and Strain Method for Natural Beekeeping