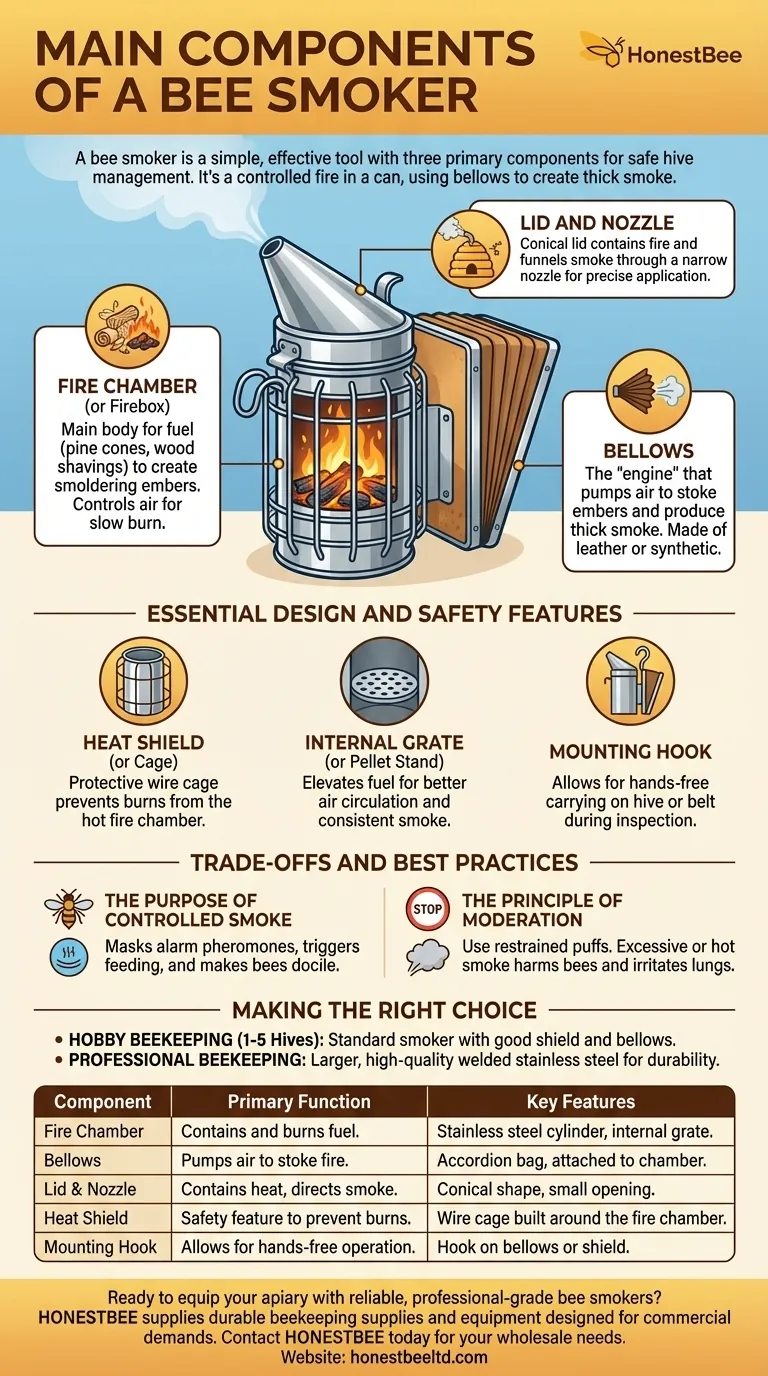

At its core, a bee smoker is a simple, effective tool with three primary components. These are the fire chamber where fuel is burned, a set of bellows to pump air and create smoke, and a lid with a nozzle to direct the smoke into the beehive. Understanding how these parts work together is the first step toward confident and safe hive management.

A bee smoker is essentially a controlled fire in a can. Its design allows a beekeeper to precisely manage airflow with bellows, creating cool, thick smoke on demand to calm the honeybee colony during inspections.

Deconstructing the Bee Smoker: Core Components

To use a smoker effectively, it's crucial to understand the function of each part. Each component plays a distinct role in generating and directing a steady, cool stream of smoke.

The Fire Chamber (or Firebox)

The fire chamber is the main body of the smoker, typically a stainless steel cylinder. This is where you place your fuel, such as pine cones, wood shavings, or crumpled newspaper.

Its design is meant to contain a small, slow-burning fire. It allows just enough air inside to keep the embers smoldering without bursting into a full flame.

The Bellows

The bellows are the "engine" of the bee smoker. This is the leather or synthetic accordion-like bag attached to the side of the fire chamber.

When you squeeze the bellows, they pump a jet of oxygen into the base of the fire chamber. This action stokes the embers, causing the fuel to produce a thick puff of smoke.

The Lid and Nozzle

The conical lid sits on top of the fire chamber, containing the fire and heat. It funnels upward and narrows into a small opening, or nozzle.

This nozzle allows you to direct the smoke with precision, aiming it at the hive entrance or under the cover before an inspection.

Essential Design and Safety Features

Beyond the core components, most smokers include several features designed for safety, convenience, and better performance.

The Heat Shield (or Cage)

Nearly all modern smokers have a protective wire cage built around the fire chamber. This is a critical safety feature that prevents you from accidentally touching the hot metal cylinder and getting burned.

The Internal Grate (or Pellet Stand)

Inside the fire chamber, at the bottom, there is often a perforated metal disc or grate. This stand holds the fuel up off the bottom of the chamber.

This elevation ensures that the air pumped from the bellows can circulate underneath the fuel, leading to more consistent and efficient smoke production.

The Mounting Hook

A simple hook is usually attached to the bellows or heat shield. This allows you to conveniently hang the smoker on the side of a hive box or attach it to your belt, freeing up your hands during an inspection.

Understanding the Trade-offs and Best Practices

Knowing the parts is only half the battle. Using the tool correctly is what separates a calm inspection from a chaotic one.

The Purpose of Controlled Smoke

The smoke doesn't harm the bees. It masks their alarm pheromones, which they release to signal danger. It also triggers a feeding response, causing them to consume honey, which makes them more docile and less likely to sting.

The Principle of Moderation

While effective, a smoker should be used with restraint. Too much smoke or smoke that is too hot can be harmful to the bees and irritate your own lungs. A few gentle puffs at the entrance and under the lid is usually all that is needed.

Making the Right Choice for Your Goal

Selecting a smoker depends largely on the scale of your beekeeping operation.

- If your primary focus is hobby beekeeping (1-5 hives): A standard, reliable smoker with a good heat shield and a solid bellow design is perfectly adequate.

- If your primary focus is professional or large-scale beekeeping: Invest in a larger smoker made from high-quality, welded stainless steel for durability and superior smoke generation over long periods.

Understanding these components empowers you to use your smoker safely, effectively, and with confidence.

Summary Table:

| Component | Primary Function | Key Features |

|---|---|---|

| Fire Chamber | Contains and burns fuel to create embers. | Stainless steel cylinder, internal grate for airflow. |

| Bellows | Pumps air to stoke the fire and produce smoke. | Leather or synthetic accordion bag, attached to chamber. |

| Lid & Nozzle | Contains heat and directs smoke precisely. | Conical shape, small opening for targeted application. |

| Heat Shield | Safety feature to prevent burns from hot metal. | Wire cage built around the fire chamber. |

| Mounting Hook | Allows for hands-free operation during inspections. | Hook on bellows or shield for hanging on hive or belt. |

Ready to equip your apiary with reliable, professional-grade bee smokers?

At HONESTBEE, we supply durable beekeeping supplies and equipment designed for the demands of commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the high-quality tools you need for safe and effective hive management.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can support your beekeeping success.

Visual Guide

Related Products

- Premium Traditional Copper Bee Smoker with Bellows

- Stainless Steel Honey Bee Smoker Hive and Honeycomb Smoker for Beekeeping

- Economy Galvanized Beekeeping Honey Bee Smoker for Wholesale

- European Stainless Steel Bee Smoker for Honey Bee Hive

- Heavy Duty Manual Bee Smoker Blower for Beekeeping

People Also Ask

- When should a beekeeper use a smoker? Essential Guide for Hive Safety and Control

- What role does the wire mesh at the end of the combustion chamber play? Vital Safety for Honey Bee Sedators

- What role does a beekeeping smoker play in the honey collection? Master Hive Control for Efficient Harvesting

- How does a beekeeping smoker facilitate hive management? Master Calm Colony Inspections

- In what way can a beekeeping smoker be used to assist in the removal of bees from honey frames? Efficient Harvest Guide

- What are some recommended fuels for a bee smoker? Achieve Calm, Safe Hive Inspections

- What is the technical function of smoking techniques in beekeeping? Optimize Your Honey Harvest Efficiency

- What is the physical mechanism by which a beekeeping smoker calms a bee colony? Master Your Hive Management Techniques