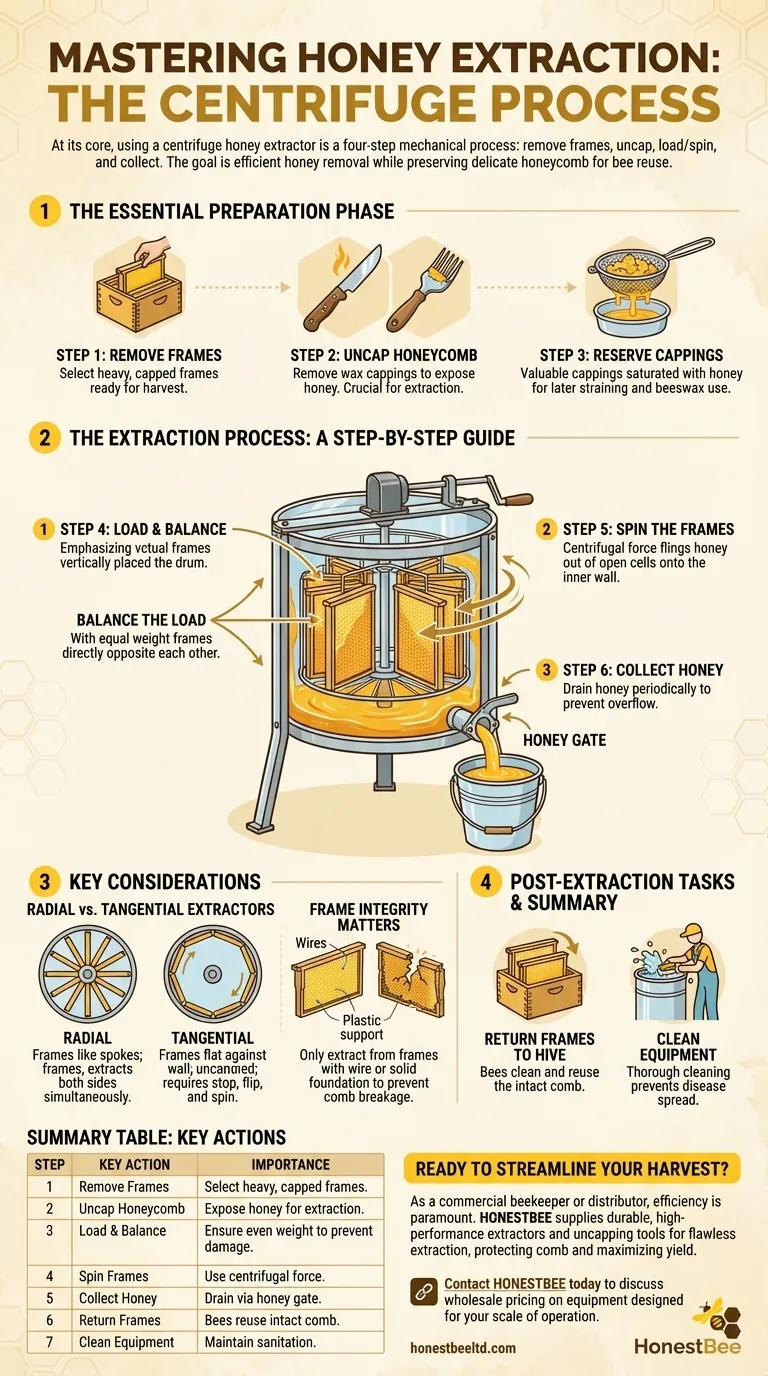

At its core, using a centrifuge honey extractor is a four-step mechanical process. You must first remove frames of capped honey from the hive, use a heated knife or fork to uncap the wax cells, place the frames inside the extractor, and then spin the machine to use centrifugal force to separate the honey from the comb.

The goal of a honey extractor isn't just to get the honey out; it's to do so efficiently while preserving the delicate honeycomb, allowing the bees to reuse it and saving them immense time and energy.

The Essential Preparation Phase

Before you can use the extractor, you must properly prepare the honey-filled frames. This stage is crucial for a clean and efficient harvest.

Step 1: Remove Frames from the Hive

Your first task is to open your beehive and select the frames that are ready for harvest. These frames will be heavy and filled with honey that the bees have sealed with a wax capping.

Step 2: Uncap the Honeycomb

The wax cappings must be removed to expose the honey. This is a critical step, as the extractor cannot pull honey from sealed cells.

Most beekeepers use a heated uncapping knife or a specialized uncapping fork to gently slice or lift off this top layer of wax.

Step 3: Reserve the Wax Cappings

The removed wax cappings are valuable. They are saturated with honey and should be set aside to be strained later. This pure beeswax has many other uses once the honey is removed.

The Extraction Process: A Step-by-Step Guide

With your frames prepared, you can begin the mechanical extraction. The key principle here is centrifugal force.

Step 4: Load the Extractor

Place your uncapped frames vertically into the baskets or slots inside the extractor drum.

It is critical to balance the load. Place frames of similar weight directly across from one another. An unbalanced extractor will vibrate violently and can be damaged.

Step 5: Spin the Frames

Begin spinning the extractor, either manually with a crank or by turning on the motor. The spinning motion creates centrifugal force, which flings the honey out of the open cells and onto the inner wall of the extractor.

The honey runs down the walls and pools at the bottom of the drum.

Step 6: Collect the Honey

Once the spinning is complete, the collected honey is drained from the bottom of the extractor through a tap or spigot, often called a honey gate. It is important to drain the honey periodically so the level does not rise high enough to interfere with the spinning frames.

Understanding the Key Considerations

While the process is straightforward, certain details can significantly impact your results. Paying attention to these factors ensures a smoother operation and higher-quality product.

Radial vs. Tangential Extractors

There are two primary types of extractors. Radial extractors position frames like spokes on a wheel, extracting honey from both sides at once.

Tangential extractors hold the frame flat against the wall, requiring you to stop midway, flip the frame, and spin again to extract honey from the other side.

Why Frame Integrity Matters

Centrifugal force puts significant stress on the honeycomb. You should not extract from frames that lack wire or a solid plastic foundation for support, as the delicate wax comb can break apart during the spinning process.

Step 7: Post-Extraction Tasks

After extracting all your frames, they should be returned to the hives. The bees will clean up the residual honey and immediately begin refilling the intact comb.

Finally, the extractor must be thoroughly cleaned with water to maintain sanitation and prevent the potential spread of disease between colonies.

Applying This to Your Harvest

Your approach to extraction will depend on your specific priorities as a beekeeper.

- If your primary focus is speed and efficiency: A motorized, radial extractor is the superior choice, as it processes both sides of multiple frames simultaneously.

- If your primary focus is preserving delicate comb: Start the extractor slowly and gradually increase the speed to minimize the initial force on the wax.

- If your primary focus is honey quality: Ensure all equipment, especially the extractor and collection containers, is impeccably clean before you begin.

By following these steps, you can ensure a successful harvest that yields pure honey while protecting the vital comb your bees worked so hard to build.

Summary Table:

| Step | Key Action | Why It's Important |

|---|---|---|

| 1 | Remove Frames from Hive | Select heavy, capped frames ready for harvest. |

| 2 | Uncap the Honeycomb | Expose honey for extraction; use a heated knife or fork. |

| 3 | Load & Balance Extractor | Ensure even weight distribution to prevent machine damage. |

| 4 | Spin the Frames | Use centrifugal force to fling honey from the comb. |

| 5 | Collect the Honey | Drain honey via the honey gate to avoid overflow. |

| 6 | Return Frames to Hive | Bees clean and reuse the intact comb, saving energy. |

| 7 | Clean Equipment | Maintain sanitation and prevent disease spread. |

Ready to streamline your honey harvest?

As a commercial beekeeper or distributor, your efficiency is paramount. HONESTBEE supplies the durable, high-performance extractors and uncapping tools you need for a flawless extraction process that protects your comb and maximizes yield.

Contact HONESTBEE today to discuss wholesale pricing on equipment designed for your scale of operation.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- Why do beekeepers have to lift a lot of weight at the end of a growing season? The Reward of a Heavy Harvest

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed