Ultimately, the primary customization available with fully automatic wax foundation machines is the precise control over the final dimensions of the wax sheets. This capability allows operators to adjust the length and width of the foundation to perfectly match the specific requirements of different beehive frame sizes.

While these machines are highly automated, their value lies not in offering endless features, but in mastering the most critical variable for beekeepers: producing dimensionally accurate foundation sheets for any type of hive, consistently and at scale.

How the Machine's Design Enables Customization

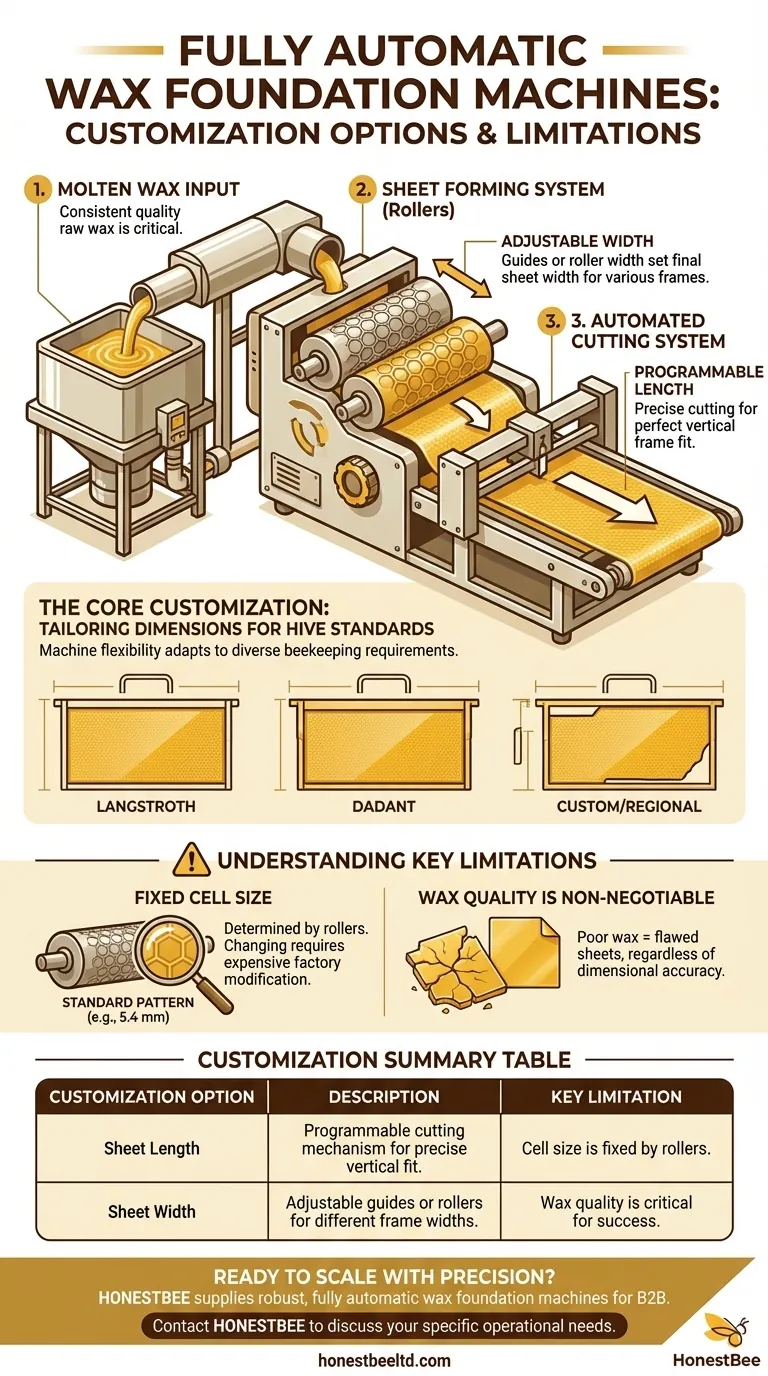

A fully automatic wax foundation machine is a system of integrated components working in sequence. Understanding this process reveals where adjustments can be made.

The Sheet Forming System

This is where the molten wax is transformed into a continuous, embossed sheet. The process is similar to a pasta maker, where wax passes through two engraved rollers. These rollers press the hexagonal cell pattern onto the wax.

The width of the final foundation sheet is determined at this stage, either by the width of the rollers themselves or by adjustable guides that control the flow of wax.

The Automated Cutting System

After the wax sheet is formed and cooled, it moves to the cutting system. This is the most significant point of user customization.

The machine uses a precise cutting mechanism, typically an automated blade, that can be programmed or adjusted to cut the continuous wax ribbon to a specific length.

The Core Customization: Adjusting Sheet Dimensions

The real-world benefit of this machinery is its flexibility to adapt to the diverse standards and practices within beekeeping.

Tailoring Sheet Width

Operators can configure the machine to produce sheets that fit seamlessly within different frame widths. This is crucial when catering to various hive standards, such as Langstroth, Dadant, or other regional or custom designs.

Setting the Exact Length

The ability to set the cutting length allows for perfect vertical fitting within a frame. This eliminates gaps that can lead to bees building undesirable burr comb, ensuring the foundation is used as intended.

Understanding the Limitations

True expertise requires acknowledging what a tool cannot do. While dimensionally flexible, these machines have important built-in constraints.

Cell Size is Fixed

The single most important limitation to understand is that the hexagonal cell size is determined by the pattern engraved on the rollers. This is not an adjustable setting.

Changing the cell size (e.g., from a standard 5.4 mm worker cell to a larger drone cell) would require physically swapping out the expensive, heavy rollers—a factory-level modification, not a simple operational adjustment.

Wax Quality is Non-Negotiable

The machine's precision is dependent on the quality of the raw beeswax fed into it. Poorly filtered or inconsistent wax will result in brittle, flawed foundation sheets, regardless of how perfectly the dimensions are set.

Making the Right Choice for Your Operation

Use this understanding to determine if a fully automatic machine aligns with your production goals.

- If your primary focus is standardizing one hive type: Your main benefit is the machine's ability to be calibrated once for perfect, repeatable dimensions, drastically increasing efficiency and quality control.

- If your primary focus is serving a market with multiple hive types: The machine's flexibility in adjusting both length and width is the critical feature that makes it a worthwhile investment.

- If your primary focus is reducing labor costs at scale: The "fully automatic" nature, requiring minimal intervention for continuous operation, is the key value proposition you should be evaluating.

By focusing on the critical customization of sheet dimensions, you can leverage this technology to meet the precise needs of your beekeeping operation.

Summary Table:

| Customization Option | Description | Key Limitation |

|---|---|---|

| Sheet Length | Programmable cutting mechanism for precise vertical fit in frames. | Cell size is fixed and determined by the machine's engraved rollers. |

| Sheet Width | Adjustable guides or rollers to match different hive frame widths. | Wax quality is critical; poor wax results in flawed sheets. |

Ready to scale your foundation production with precision?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, fully automatic wax foundation machines. Our wholesale-focused operations ensure you get the reliable equipment needed to produce dimensionally perfect foundation sheets for any hive type, consistently and at scale.

Contact HONESTBEE today to discuss how our machines can be tailored to your specific operational needs.

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What physical benefits do high-precision hydraulic presses provide? Improve Beeswax Foundation Stability and Density

- What role does a foundation sheet making machine play in the value-added processing of beeswax? Maximize Hive Yields

- Why is the wax foundation machine essential for a production cycle? Build a Self-Sufficient Beekeeping Business

- Why is torsion and bending stress analysis necessary for beeswax processing machinery? Ensure Shaft Reliability

- How does beekeeping wax processing equipment improve profitability? Unlock High-Margin Value-Added Revenue

- What role does standardized comb foundation equipment play in the production of high-quality bee bread?

- What is the role of professional beeswax processing equipment? Achieve Diversified Outputs for Beekeeping Enterprises

- Why are a specialized water circulation pump and a cooling storage tank necessary? Master Beeswax Foundation Cooling