At its core, a filling machine is a specialized piece of equipment designed to accurately and efficiently deposit a specific amount of product into a container. It is the workhorse of any packaging line, replacing manual scooping and pouring to dramatically increase production speed and guarantee that every bottle, jar, or pouch receives a consistent, repeatable amount of product. This precision is achieved by measuring the product based on a set parameter, such as volume, weight, time, or count.

The fundamental purpose of a filling machine is to ensure product consistency and accelerate production. The critical decision is not about finding the "best" machine overall, but selecting the technology—primarily volumetric or weight-based—that is perfectly suited to your product's characteristics and your operational scale.

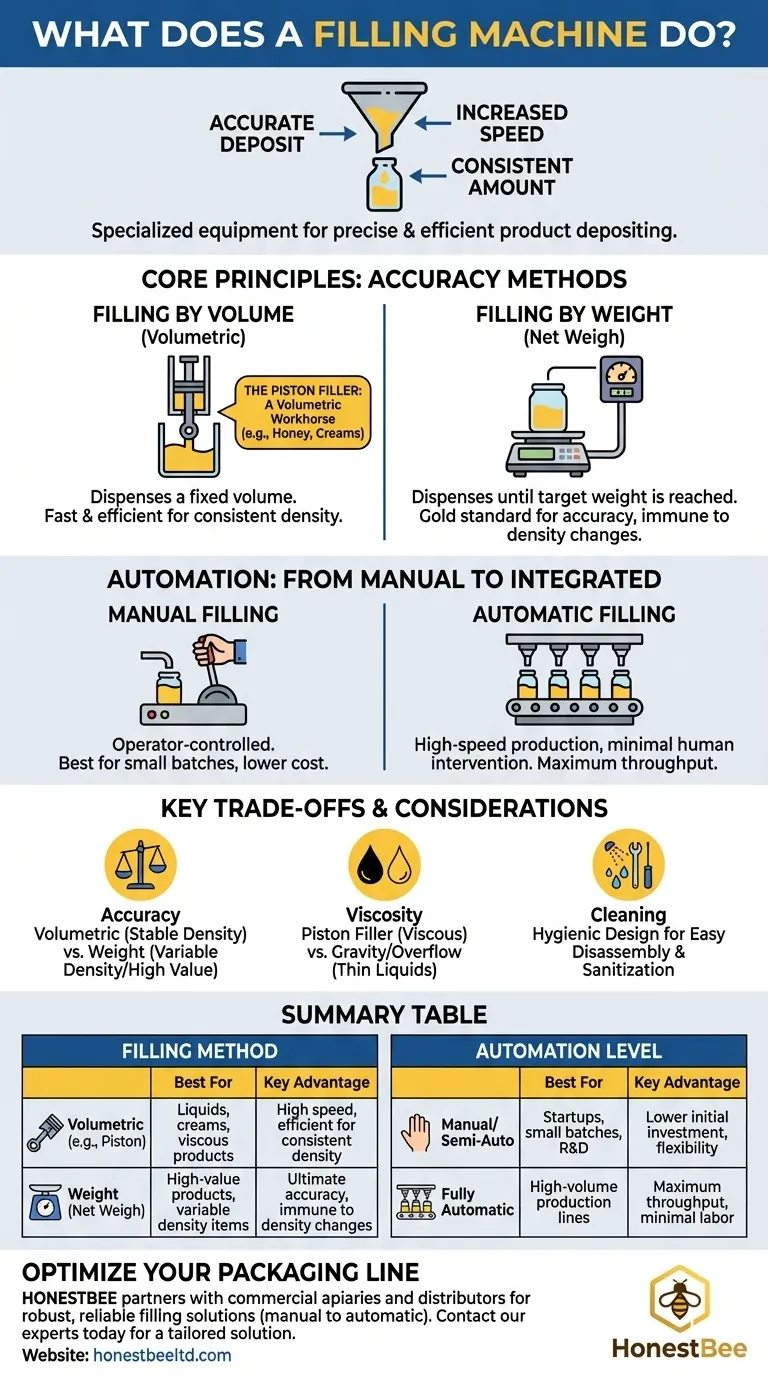

The Core Principle: How Fillers Achieve Accuracy

A filling machine's primary value lies in its repeatable accuracy. This is accomplished through two principal methods of measurement: filling by volume or filling by weight.

Filling by Volume (Volumetric)

A volumetric filler dispenses a precise volume of product into each container. This method is extremely fast and efficient, making it ideal for most liquids and products that have a consistent density.

The machine is calibrated to dispense, for example, exactly 500 milliliters. As long as the product's density doesn't change, each 500ml fill will also have the same weight, ensuring uniformity.

The Piston Filler: A Volumetric Workhorse

One of the most common and versatile types of volumetric fillers is the piston filler. It operates with a simple, robust mechanism perfect for a wide range of product viscosities.

A piston draws a set volume of product from a hopper into a cylinder. The piston then pushes forward, forcing the product out of the cylinder through a nozzle and into the waiting container. This design is highly effective for thick, viscous products like honey, creams, and gels, as well as products containing particulates like sauces or salsas.

Filling by Weight (Net Weigh)

A weighing filling machine dispenses product until a target weight is reached in the container. The container sits on a scale (a load cell) that sends a signal to the machine to stop dispensing once the correct weight is achieved.

This method is the gold standard for accuracy when the product's density can vary or when the final product weight is a critical quality or regulatory requirement.

Automation: From Manual to Fully Integrated

The level of automation is a separate but equally important consideration that directly impacts production speed and labor costs.

Manual Filling Machines

A manual filler requires an operator for every step of the process. The operator typically places the container, activates the fill with a lever or foot pedal, and then removes the filled container.

These machines are best for small-scale operations, lab testing, or startup businesses where the initial investment must be low.

Automatic Filling Machines

An automatic filling machine is designed for high-speed production with minimal human intervention. It is integrated into a conveyor line that automatically moves containers into position, fills them, and moves them to the next station (e.g., capping or labeling).

These systems are programmed to control the entire filling process, ensuring maximum throughput and consistency for large-scale manufacturing.

Understanding the Trade-offs

Choosing the right filler requires balancing accuracy, speed, product type, and cost.

Volumetric vs. Weight: The Accuracy Question

Volumetric fillers are extremely accurate if your product's density is stable. However, if temperature changes cause your product to expand or contract, the volume will remain the same but the weight will change.

Weight fillers are immune to changes in density, temperature, or aeration. They deliver a precise weight every time, making them superior for products sold by weight or for high-value goods where giveaway must be minimized.

Product Viscosity Is Key

The physical nature of your product is a primary decision driver. A piston filler excels with viscous liquids that are difficult to pour. For thin, free-flowing liquids, other types of volumetric fillers (like gravity or overflow fillers) may be more suitable.

Cleaning and Hygiene

For food, beverage, or pharmaceutical applications, ease of cleaning is critical. Many piston fillers are specifically engineered for easy disassembly without tools. This allows for thorough cleaning and sanitization, preventing cross-contamination and ensuring product safety.

Making the Right Choice for Your Goal

Your choice depends entirely on your product, production volume, and required accuracy.

- If your primary focus is handling viscous liquids or creams (like honey or lotions): A volumetric piston filler is engineered for this task, providing consistent volume and handling thick consistencies effectively.

- If your primary focus is maximum accuracy for a high-value product: A net weigh filling machine is the most reliable choice, as it guarantees a precise weight in every container regardless of density changes.

- If your primary focus is high-speed, large-scale production: An automatic filling machine, whether volumetric or weight-based, is essential to meet throughput demands with minimal labor.

- If your primary focus is small-batch production or starting a new operation: A manual or semi-automatic machine offers a lower initial investment and the flexibility to get started quickly.

Understanding these core principles empowers you to select a machine that serves as a reliable foundation for your entire production line.

Summary Table:

| Filling Method | Best For | Key Advantage |

|---|---|---|

| Volumetric (e.g., Piston) | Liquids, creams, viscous products (honey, sauces) | High speed, efficient for consistent density |

| Weight (Net Weigh) | High-value products, variable density items | Ultimate accuracy, immune to density changes |

| Automation Level | Best For | Key Advantage |

| Manual/Semi-Auto | Startups, small batches, R&D | Lower initial investment, flexibility |

| Fully Automatic | High-volume production lines | Maximum throughput, minimal labor |

Ready to Optimize Your Packaging Line?

Selecting the right filling technology is critical for your product's consistency and your operation's profitability. HONESTBEE partners with commercial apiaries and beekeeping equipment distributors to provide robust, reliable filling solutions.

We understand the unique challenges of handling products like honey, creams, and waxes. Our expertise helps you choose the right equipment—from manual piston fillers for precise small-batch work to high-speed automatic systems for large-scale production—ensuring accuracy, efficiency, and easy cleaning.

Let's discuss how we can support your growth. Contact our experts today for a tailored solution.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- What are the advantages of automatic honey filling machines? Boost Market Competitiveness and Brand Value

- What is the role of automated honey filling and processing equipment in maintaining product quality? Protect Your Harvest

- What are the advantages of using high-precision honey filling machines? Optimize Your Commercial Honey Production

- Why are professional honey-filling and sealing machines essential for stingless bee honey? Maximize Value & Purity

- How does industrial honey-filling equipment meet food safety standards? Secure Global Export Compliance with Precision

- How do automated honey filling machines facilitate brand value addition? Scale Your Apiary into a Premium Retail Brand

- What are the key advantages of volumetric filling machines? Boost Packaging Speed & Flexibility

- What are the advantages of using automated filling machines for apitherapy? Scaling Medical-Grade Production