At its core, the Langstroth hive's dominance in modern beekeeping stems from one key principle: modularity. This design, built from a series of standardized, stackable boxes, allows beekeepers to easily inspect the colony, manage pests, and expand the hive. Its components are engineered specifically for efficient honey harvesting and colony health management.

The Langstroth hive isn't just a box; it's an engineered system. Its true value lies in its interchangeable components and respect for "bee space," which empowers beekeepers to manage colonies with unparalleled precision and efficiency.

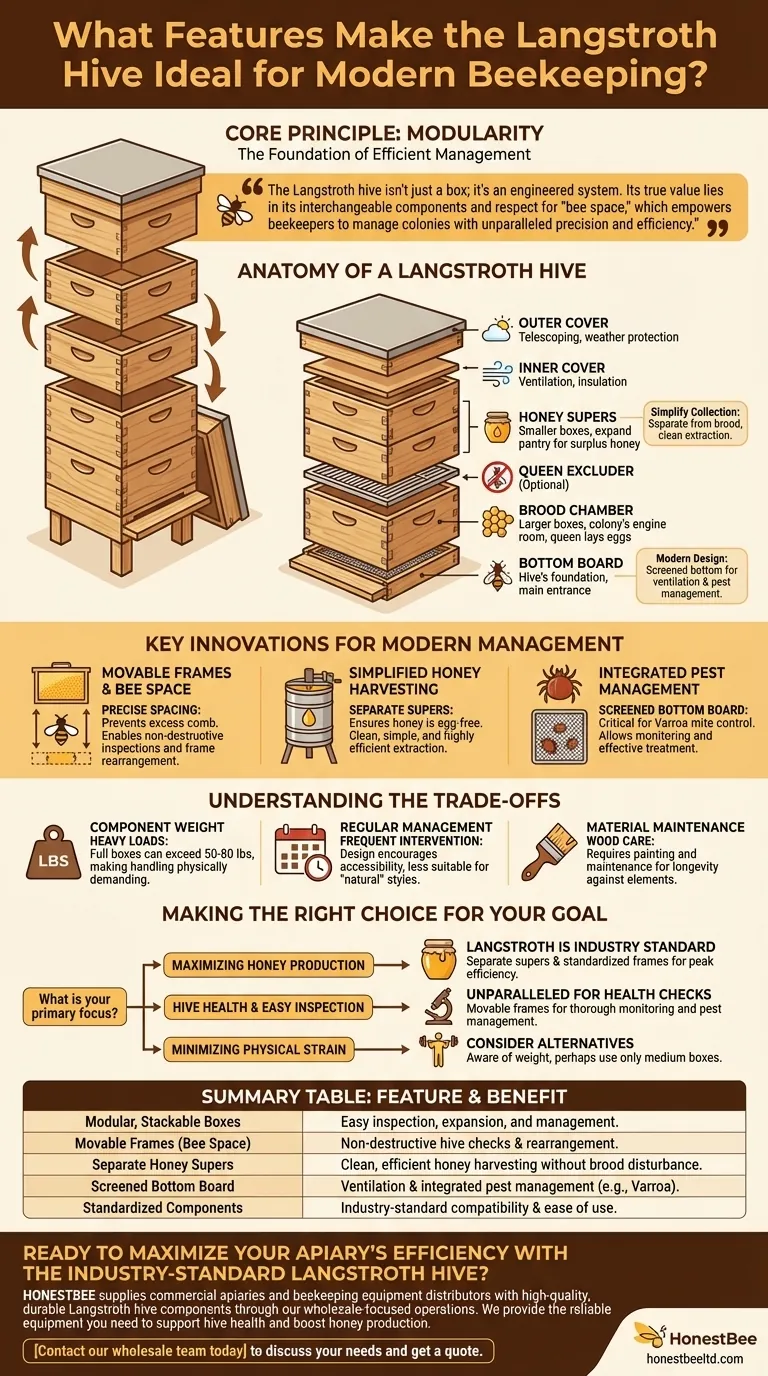

The Anatomy of a Langstroth Hive

The hive is a vertical stack of components, each serving a distinct purpose for the colony and the beekeeper.

The Brood Box: The Colony's Engine Room

The bottom, larger boxes are the brood chambers. This is the heart of the colony, where the queen lays her eggs and the bees raise the next generation.

Honey Supers: The Expandable Pantry

Smaller boxes, known as honey supers, are placed on top of the brood chamber. These are specifically for the bees to store surplus honey, making collection straightforward for the beekeeper without disturbing the brood nest.

The Inner and Outer Covers: Climate Control

An inner cover provides ventilation and insulation, while the outer cover (often telescoping) protects the hive from rain, sun, and harsh weather. This two-part system helps regulate the hive's internal environment.

The Bottom Board: The Hive's Foundation

This component serves as the floor of the hive and includes the main entrance for the bees. Modern designs often feature a screened bottom board for ventilation and pest management.

Key Innovations for Modern Management

The Langstroth design introduced features that directly address the primary goals of today's beekeepers: hive health and productivity.

The Power of Movable Frames

The single most important innovation is the hive's precise spacing around each frame. This "bee space" prevents bees from sealing the frames together with excess comb, allowing the beekeeper to remove, inspect, and rearrange individual frames without destroying the hive structure.

Simplified Honey Harvesting

By separating the brood chamber from the honey supers (often with an optional queen excluder), the design ensures honey frames are free of eggs and larvae. This makes the extraction process clean, simple, and highly efficient.

Integrated Pest Management

The modern screened bottom board is a critical tool for controlling Varroa mites, a major threat to honeybees. It allows mites to fall through the screen onto a mite grid or inspection tray, letting the beekeeper monitor infestation levels and manage treatments effectively.

Understanding the Trade-offs

While highly effective, the Langstroth system is not without its challenges.

Component Weight

A deep brood box or a honey super filled with honey can be extremely heavy, often exceeding 50-80 pounds. This can make inspections and harvesting physically demanding.

Regular Management is Assumed

The design's strength is its accessibility for management. This can be a drawback for those seeking a more hands-off, "natural" beekeeping style, as the system implicitly encourages frequent intervention.

Material Maintenance

Most Langstroth hives are made of wood, which offers excellent insulation and breathability for the colony. However, wood requires regular painting and maintenance to protect it from the elements and ensure a long service life.

Making the Right Choice for Your Goal

Understanding these features helps you align the hive type with your beekeeping objectives.

- If your primary focus is maximizing honey production: The Langstroth's separate honey supers and standardized, easily extractable frames make it the industry standard for efficiency.

- If your primary focus is hive health and easy inspection: The movable frames are unparalleled for conducting thorough health checks and implementing integrated pest management strategies.

- If your primary focus is minimizing physical strain: Be aware that the boxes can become very heavy, and you may want to consider using only medium-sized boxes for all functions.

Ultimately, the Langstroth hive's enduring success lies in its ability to perfectly balance the needs of the honeybee colony with the goals of the beekeeper.

Summary Table:

| Feature | Benefit for Modern Beekeeping |

|---|---|

| Modular, Stackable Boxes | Easy inspection, expansion, and management. |

| Movable Frames (Bee Space) | Non-destructive hive checks and frame rearrangement. |

| Separate Honey Supers | Clean, efficient honey harvesting without disturbing the brood. |

| Screened Bottom Board | Ventilation and integrated pest management (e.g., Varroa mites). |

| Standardized Components | Industry-standard equipment compatibility and ease of use. |

Ready to maximize your apiary's efficiency with the industry-standard Langstroth hive?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable Langstroth hive components through our wholesale-focused operations. We provide the reliable equipment you need to support hive health and boost honey production.

Contact our wholesale team today to discuss your needs and get a quote.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- Should a beginner try a different type of hive? Start with a Langstroth for a solid foundation.

- How does the orientation of the hive sides benefit comb construction? Ensure Straight, Movable Combs for Easier Hive Management

- What are the advantages of standard Langstroth movable-frame beehives? Boost Honey Yields by 1.8x

- Why were wooden hives traditionally preferred? For Natural Beekeeping Aligned with Bee Biology

- Why might a beginner be advised to start with a Langstroth hive? Unlock a Supportive Beekeeping Ecosystem