In beekeeping, nothing goes to waste. After honey is extracted, the beeswax cappings and residual wax on the frames are not discarded but are instead considered a valuable secondary harvest. This wax is systematically collected, cleaned, and repurposed, either for use back in the hive or for creating a variety of valuable beeswax products.

The core principle is resourcefulness. Wax left after a honey harvest can be cleaned and either returned to the hive, saving the bees immense energy, or rendered into pure beeswax blocks for use in candles, cosmetics, and new hive foundations.

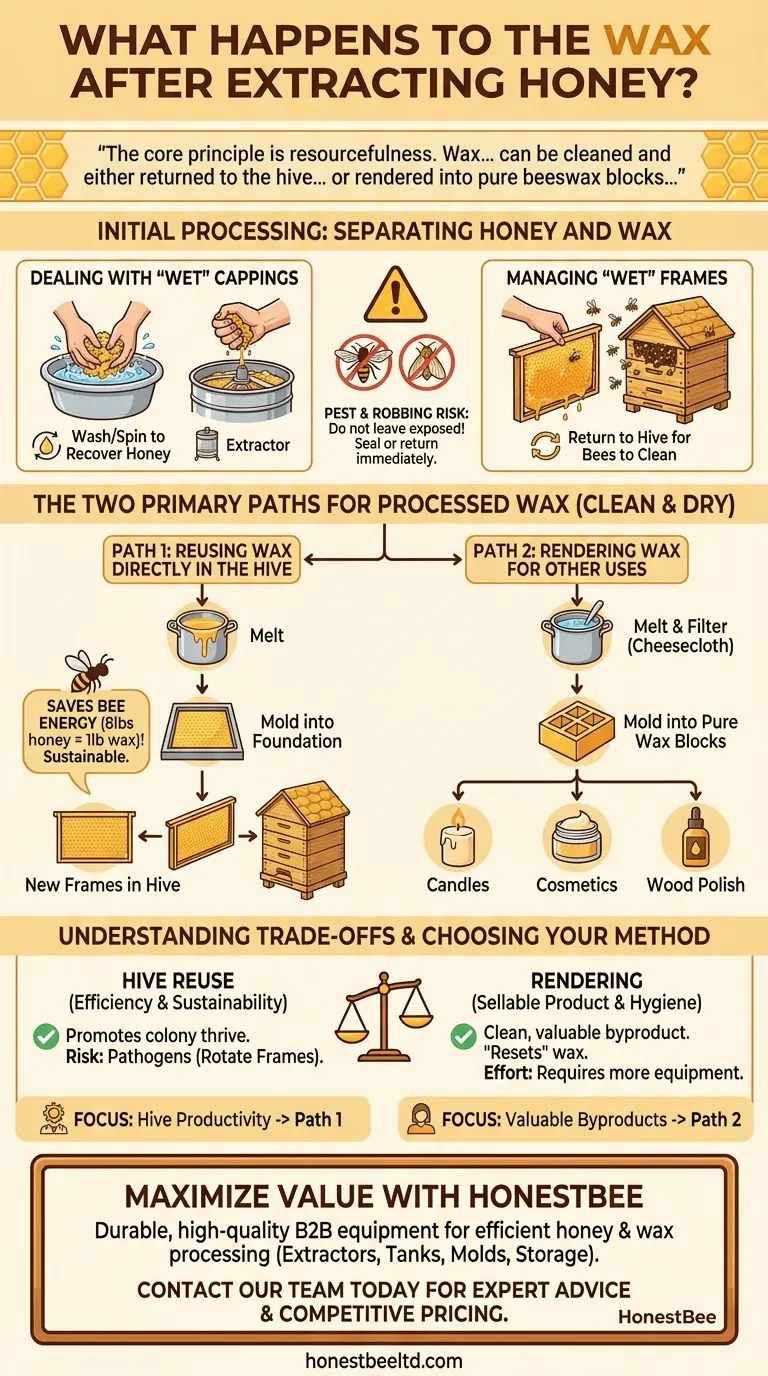

Initial Processing: Separating Honey and Wax

The first step after extraction is to deal with the "wet" cappings and frames, which are still coated in a layer of honey. Proper management at this stage is crucial for maximizing your harvest and preventing problems.

Dealing with "Wet" Cappings

The wax cappings, which are sliced off the honeycomb to release the honey, are saturated with residual honey. This honey must be recovered.

Beekeepers often wash the cappings in warm water to dissolve the remaining honey, creating a sweet solution that can be used for feeding bees. Alternatively, the cappings can be squeezed or spun in an extractor to reclaim as much liquid honey as possible before the wax is processed further.

Managing "Wet" Frames

Frames that have been through an extractor still have a thin film of honey. Leaving these frames out in the open is a mistake, as they will quickly attract pests and robber bees from other colonies.

The most common and beneficial practice is to place these wet frames back into the hive they came from. The bees will diligently clean every last drop of honey, transferring it to their winter stores. This provides them with valuable resources and leaves you with perfectly clean, dry comb.

The Two Primary Paths for Processed Wax

Once the wax is clean and dry—whether it's from cappings or old comb—you have two main options. The path you choose depends on your goals as a beekeeper.

Path 1: Reusing Wax Directly in the Hive

The most sustainable use for old beeswax is to put it right back into the production cycle of your own apiary.

Clean, rendered beeswax can be melted down and used in a mold to create new foundation sheets. These sheets are placed into empty frames, giving bees a head start on building new comb. This saves the bees a tremendous amount of energy, as they must consume about eight pounds of honey to produce just one pound of wax.

Path 2: Rendering Wax for Other Uses

If you have a surplus of wax or wish to create other products, you can render it into pure, clean blocks.

This process involves melting the wax in water, which allows debris to sink and the clean wax to float. The molten wax is then carefully strained, often through multiple layers of cheesecloth, to remove any remaining impurities. Finally, the liquid wax is poured into molds to cool and harden into solid beeswax bricks.

Common Products from Rendered Beeswax

These clean beeswax blocks are highly versatile and can be used to make a wide range of popular products, including:

- Candles: Prized for their bright flame and pleasant, natural scent.

- Cosmetics: A key ingredient in lip balms, lotions, and soaps.

- Wood Polish: Creates a natural, protective finish for furniture.

Understanding the Trade-offs

Choosing how to process your wax involves balancing efficiency, hive health, and your own time and resources.

Returning Wax vs. Rendering It

Returning cleaned comb and foundation to the hive is incredibly efficient and helps the colony thrive. However, old comb can potentially harbor pathogens. Many beekeepers rotate out old frames every few years and render the wax to maintain hive hygiene.

Rendering wax requires more equipment and effort but results in a clean, sellable product and removes old material from the hive. It effectively "resets" the wax, ensuring it's free of contaminants.

The Pest and Robbing Risk

The most significant immediate risk is improper storage of "wet" cappings and frames. The scent of honey is a powerful attractant for pests like wax moths and hornets, as well as bees from neighboring hives.

Never leave honey-coated equipment exposed. Either return it to the bees to clean immediately or store it in sealed, pest-proof containers until you can process it.

Choosing the Right Method for Your Apiary

Your decision on how to handle your wax should align with your primary beekeeping goals.

- If your primary focus is hive productivity and sustainability: Return the cleaned frames to the hive and use rendered wax to create new foundation sheets for the colony.

- If your primary focus is creating valuable byproducts: Dedicate your time to rendering, filtering, and molding the wax into clean blocks for sale or for making candles, balms, and other crafts.

Ultimately, the wax from your harvest is a valuable resource that completes the cycle of beekeeping.

Summary Table:

| Wax Processing Step | Key Action | Primary Outcome |

|---|---|---|

| Initial Processing | Separate honey from wax cappings/frames; return frames to hive for bees to clean. | Recover honey, prevent pests, obtain clean wax. |

| Path 1: Hive Reuse | Melt and mold clean wax into new foundation sheets. | Saves bees energy, promotes hive sustainability. |

| Path 2: Rendering | Melt wax, filter through cheesecloth, pour into molds to create blocks. | Produces pure beeswax for candles, cosmetics, polish. |

Maximize the value of your apiary's resources with HONESTBEE.

Just as the wax from a honey harvest is a valuable byproduct, having the right equipment is key to efficient and profitable beekeeping. Whether you manage a commercial apiary or distribute beekeeping supplies, HONESTBEE provides the durable, high-quality tools you need—from extractors and uncapping tanks to foundation molds and storage containers—to streamline your honey and wax processing.

Let's discuss how our wholesale-focused solutions can support your operation's productivity and sustainability.

Contact our team today for expert advice and competitive pricing on commercial-grade beekeeping equipment.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production

- What is the flashpoint of beeswax? Essential Safety and Quality Tips for Beekeepers

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs