At its core, a 10-frame hive box is the industry-standard component for a modern beehive, designed to hold exactly ten removable frames. These boxes, which serve as the floors of the hive's "house," come in different vertical depths and are known for being the most common, productive, and heaviest option available to beekeepers.

The 10-frame hive system is the default choice for maximizing honey production due to its large size and universal availability. However, its significant weight when full is a critical trade-off that every beekeeper must carefully consider.

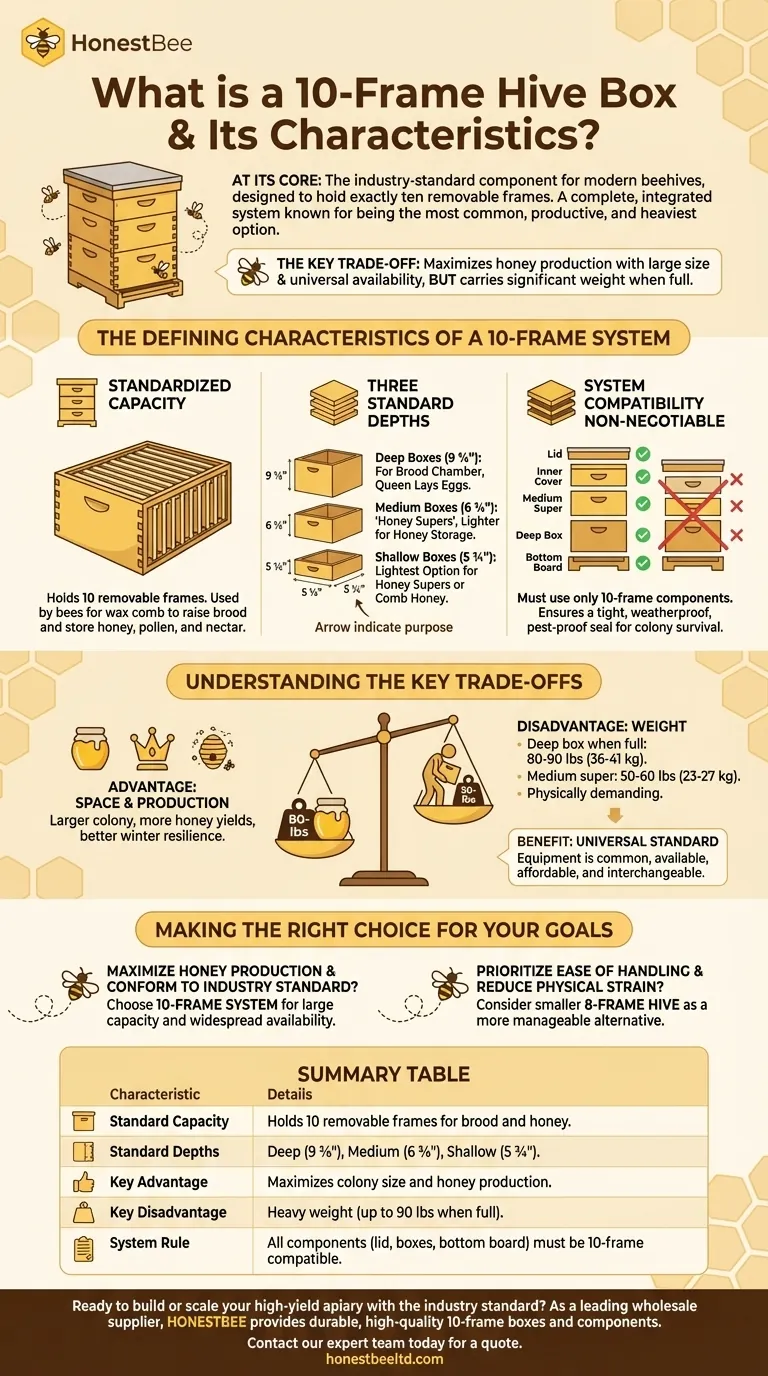

The Defining Characteristics of a 10-Frame System

A 10-frame hive is more than just a box; it's a complete, integrated system. Understanding its components and how they work together is fundamental to beekeeping.

Standardized Capacity

The defining feature is its capacity to hold ten frames side-by-side. These frames are what the honey bees use to build their wax comb, which is then used for raising young bees (brood) and storing honey, pollen, and nectar.

Three Standard Depths

While the length and width are fixed, 10-frame boxes come in three standard heights, or depths, each with a specific purpose.

- Deep Boxes (9 ⅝”): These are typically used for the bottom-most sections of the hive, known as the brood chamber, where the queen lays her eggs.

- Medium Boxes (6 ⅝”): Often called "honey supers," these are placed on top of the brood chamber for honey storage. Their shallower depth makes them lighter and easier to lift.

- Shallow Boxes (5 ¾”): The lightest option, also used for honey supers or for creating specialty comb honey.

Why System Compatibility is Non-Negotiable

A critical rule in beekeeping equipment is that all 10-frame components must be used with other 10-frame components. You cannot mix and match an 8-frame box with a 10-frame lid or bottom board.

This strict compatibility ensures a tight, weatherproof, and pest-proof seal for the hive. Any gaps would expose the colony to rain, wind, and invaders like wasps or mice, jeopardizing their survival.

Understanding the Key Trade-offs

The choice to use a 10-frame system is primarily a decision between maximum space and manageable weight. While it's the standard, it isn't the right choice for everyone.

The Advantage of Space and Production

More space means more room for the queen to lay and for workers to store honey. A 10-frame hive can support a larger, more robust colony, which often translates to greater honey yields compared to smaller hive formats. This larger population can also make the colony more resilient over winter.

The Critical Disadvantage of Weight

This extra space comes at a cost: weight. A deep 10-frame box filled with brood, pollen, and honey can easily weigh 80 to 90 pounds (36-41 kg). Even a medium honey super can weigh 50-60 pounds (23-27 kg).

Lifting these boxes for inspections and honey harvesting is the most physically demanding part of beekeeping. This weight can be a significant barrier for individuals with back problems or limited physical strength.

The Benefit of a Universal Standard

Because the 10-frame hive is the most common size in North America, equipment is everywhere. It is typically easier to find, more affordable, and interchangeable between suppliers. It is also easier to purchase established colonies or nucleus hives ("nucs") that are sized for this standard equipment.

Making the Right Choice for Your Goals

Your decision should be based on a realistic assessment of your physical abilities and beekeeping ambitions.

- If your primary focus is maximizing honey production and conforming to the industry standard: The 10-frame system is the established choice for its large capacity and widespread equipment availability.

- If your primary focus is ease of handling and reducing physical strain: The significant weight of a 10-frame box is a major drawback; a smaller 8-frame hive is a popular and more manageable alternative.

Ultimately, choosing the right hive size is about balancing the productive needs of your bees with your own physical capabilities as a beekeeper.

Summary Table:

| Characteristic | Details |

|---|---|

| Standard Capacity | Holds 10 removable frames for brood and honey. |

| Standard Depths | Deep (9 ⅝"), Medium (6 ⅝"), Shallow (5 ¾"). |

| Key Advantage | Maximizes colony size and honey production. |

| Key Disadvantage | Heavy weight (up to 90 lbs when full). |

| System Rule | All components (lid, boxes, bottom board) must be 10-frame compatible. |

Ready to build or scale your high-yield apiary with the industry standard?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-quality 10-frame boxes and components you need to maximize your operation's productivity. Our wholesale-focused operations ensure you get the reliable equipment your business depends on.

Contact our expert team today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Langstroth Honey Bee Box Hive Boxes for Different Depths

- Australian Langstroth Beehive Boxes for Beekeeping Wholesales

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- What is a hive body in a Langstroth hive? Essential Guide to Brood Chambers and Standard Dimensions

- How do frame sizes relate to the different types of Langstroth boxes? Master Hive Compatibility Today

- What is the function of Langstroth hive bodies? Optimize Your Colony Management and Commercial Efficiency

- How is checking honey supers in a Langstroth hive different from inspecting Honey Flow supers? A Guide to Disruptive vs. Non-Invasive Methods

- What are the primary functions of multi-layer beehives and standard 235 x 230 mm frames in professional apiaries?