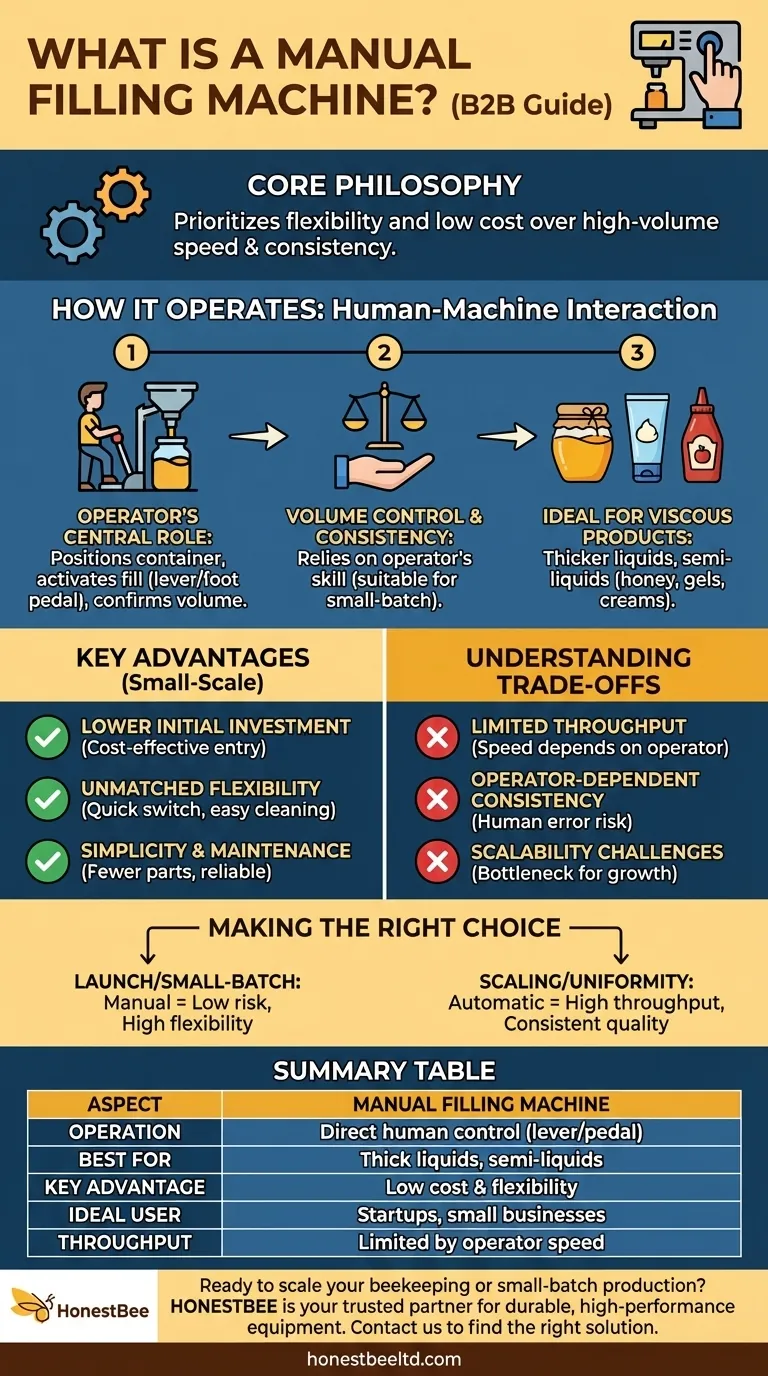

At its core, a manual filling machine is a device that requires direct human involvement to dispense a product into containers. An operator physically places each bottle or jar, initiates the fill, and controls the amount of product dispensed, making it a completely hands-on process.

The critical distinction is not just about human involvement, but about operational philosophy. Manual filling machines prioritize flexibility and low cost over the speed and high-volume consistency offered by automated systems.

How a Manual Filling Machine Operates

A manual filler is fundamentally a simple tool designed to provide control and assistance to an operator, rather than replacing them. Its design is centered around this human-machine interaction.

The Central Role of the Operator

The entire process hinges on the operator. They are responsible for positioning the container, activating the fill (often via a lever or foot pedal), and visually confirming the correct volume before moving to the next container.

Volume Control and Consistency

While some manual fillers have mechanisms to help measure a dose, final consistency often relies on the operator's skill. This level of precision is perfectly acceptable for many small-batch products.

Ideal for Viscous Products

These machines excel with thicker liquids and semi-liquids where flow can be managed easily by the operator. Products like honey, gels, creams, and sauces are common applications.

Key Advantages for Small-Scale Operations

The appeal of a manual machine is not its speed, but its practicality for businesses that are starting out or have specialized needs.

Lower Initial Investment

Manual fillers are significantly more cost-effective than their automatic counterparts. This low barrier to entry makes them an ideal starting point for startups, small businesses, and even hobbyists.

Unmatched Flexibility

Operators can switch between different container sizes and shapes with minimal setup time. Cleaning the machine between different product batches is also a much simpler and faster process.

Simplicity and Maintenance

With fewer moving parts and no complex electronics or programming, manual machines are generally easier to maintain and troubleshoot. This reliability is a major benefit for operations without a dedicated maintenance team.

Understanding the Trade-offs

Choosing a manual filler means accepting certain limitations in exchange for its benefits. Objectively weighing these trade-offs is crucial.

Limited Throughput and Speed

The production rate is entirely dependent on the speed and stamina of the human operator. This makes it unsuitable for high-volume production demands where speed is a critical factor.

Operator-Dependent Consistency

While an experienced operator can be very consistent, the potential for human error in fill levels is always present. Automated systems provide a level of precision and repeatability that a manual process cannot match.

Scalability Challenges

A manual filling machine can quickly become a production bottleneck as a business grows. When demand outpaces the operator's capacity, the only solution is to invest in a semi-automatic or fully automatic system.

Making the Right Choice for Your Goal

The decision between manual and automatic filling is a strategic one, tied directly to your production volume and business objectives.

- If your primary focus is launching a new product or managing a small-batch operation: A manual filling machine provides the lowest financial risk and the greatest operational flexibility.

- If your primary focus is scaling production and guaranteeing product uniformity: An automatic filling machine is the necessary investment to achieve high throughput and consistent quality.

Choosing the right equipment is about aligning your tools with your current scale and future ambition.

Summary Table:

| Aspect | Manual Filling Machine |

|---|---|

| Operation | Direct human control (lever/foot pedal) |

| Best For | Thick liquids, semi-liquids (honey, gels, creams) |

| Key Advantage | Low initial cost & high flexibility |

| Ideal User | Startups, small businesses, hobbyists |

| Throughput | Limited by operator speed |

Ready to scale your beekeeping or small-batch production?

A manual filling machine is the perfect, cost-effective starting point for managing your honey, creams, or other viscous products. As your business grows, HONESTBEE is your trusted partner for the next step. We supply durable, high-performance beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations.

Let's discuss your production goals. Contact our experts today to find the right equipment for your operation's scale and ambition.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- How do filling machines work? A Guide to Precision, Speed, and Choosing the Right Technology

- Why is specialized honey-filling and packaging machinery vital for commercial apiaries? Boost Your Profitability Today

- What are the technical and functional advantages of honey sachet packaging? Optimize Your Honey Portability

- How are commercial honey harvesting, filtering, and filling machines utilized to study the loss of bee productivity?

- What are the advantages of using automated honey filling machines? Boost Precision & Hygiene in Your Apiary

- How does industrial honey packaging equipment support pollination sustainability? Empower Your Commercial Honey Business

- Why must honey harvesting and filling equipment be adapted for specific bee species? Biology Meets Engineering

- How do honey-filling machines support conservation? Drive Profit and Protect Ecosystems with Professional Equipment