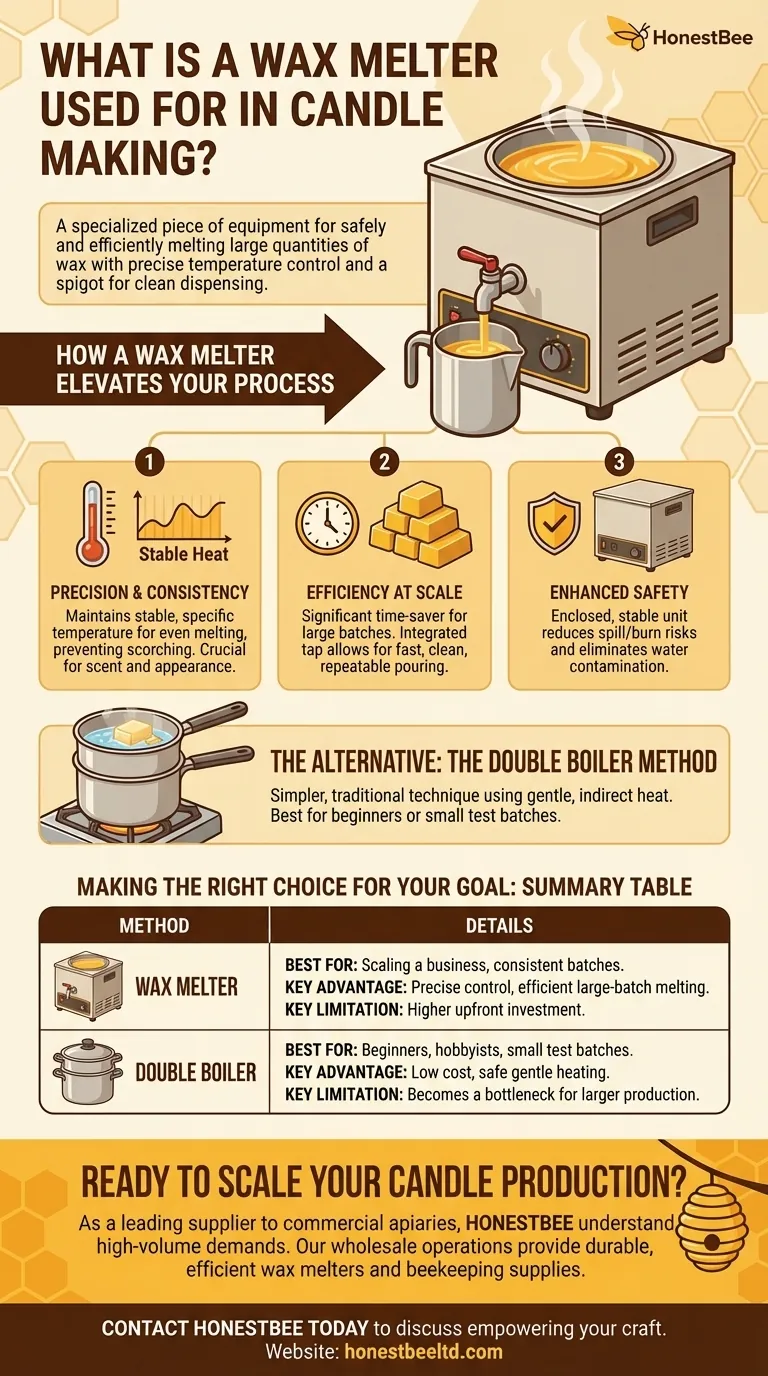

A professional wax melter is a specialized piece of equipment designed to safely and efficiently melt large quantities of wax for candle making. Unlike makeshift methods, it provides precise temperature control and features a spigot or tap at the bottom, allowing you to dispense melted wax directly and with minimal mess.

The core purpose of a wax melter is to move beyond the limitations of hobbyist methods. It addresses the fundamental needs for safety, consistency, and scalability as you transition from making a few candles to producing them in larger, more predictable batches.

How a Wax Melter Elevates Your Process

Using a dedicated melter is about gaining control over the most critical variable in candle making: heat. This control has a direct impact on the quality and efficiency of your work.

Precision and Consistency

A quality wax melter maintains a stable, specific temperature. This is crucial because different waxes have different ideal melting and pouring temperatures.

Consistent heat ensures your wax melts evenly without scorching, which can affect scent throw and the final appearance of your candle.

Efficiency at Scale

For anyone producing more than a few candles at a time, a melter is a significant time-saver. It can melt large blocks or batches of wax far more quickly and with less supervision than a double boiler.

The integrated tap allows for clean, fast, and repeatable pouring, dramatically increasing your production speed.

Enhanced Safety

A dedicated melter is an enclosed, stable unit, which significantly reduces the risk of spills and burns associated with open pots on a stovetop.

It also eliminates the possibility of water accidentally splashing into your wax—a common issue with the double boiler method that can ruin a batch and cause dangerous sputtering.

The Alternative: The Double Boiler Method

Before investing in a melter, most candle makers start with a simpler, traditional technique.

How It Works

The double boiler method involves placing a pouring pot or heat-safe bowl containing your wax inside a larger pot of simmering water.

This approach provides gentle, indirect heat, which is a safe way to melt wax without burning it. It is considered the safest starting option, especially for waxes like beeswax that melt at a relatively low temperature (around 147°F or 64°C).

When It Makes Sense

This method is perfectly suitable for beginners, crafting a handful of candles, or running small test batches with new fragrance oils or waxes.

Understanding the Trade-offs

Choosing your melting method is a decision between initial cost and long-term operational efficiency.

Investment vs. Throughput

A wax melter is a significant upfront investment compared to a pot and a bowl. However, for a business, its cost is quickly offset by increased productivity, reduced wax waste, and lower energy consumption per candle.

The double boiler method has a very low barrier to entry but becomes a bottleneck as soon as you need to scale up production.

Control vs. Simplicity

A dedicated melter gives you precise, thermostat-controlled heat. The double boiler's temperature is less exact and requires more hands-on monitoring.

A Note on Wax Quality

Regardless of your melting method, the quality of your final candle depends entirely on using clean wax. Debris or impurities will clog the wick and lead to uneven burning, tunneling, or excessive smoke.

Making the Right Choice for Your Goal

Your ideal tool depends entirely on your specific candle-making objectives.

- If your primary focus is learning or hobbyist creation: The double boiler method is a safe, effective, and low-cost way to master the fundamentals.

- If your primary focus is scaling a business or producing consistent batches: A dedicated wax melter is a non-negotiable investment for safety, efficiency, and professional-quality results.

Ultimately, selecting the right equipment is about empowering your craft and removing obstacles to growth.

Summary Table:

| Method | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Wax Melter | Scaling a business, consistent batches | Precise temperature control, efficient large-batch melting | Higher upfront investment |

| Double Boiler | Beginners, hobbyists, small test batches | Low cost, safe and gentle heating | Becomes a bottleneck for larger production |

Ready to scale your candle production with professional-grade equipment?

As a leading supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the demands of high-volume production. Our wholesale-focused operations provide the durable, efficient wax melters and beekeeping supplies you need to ensure safety, consistency, and growth.

Contact HONESTBEE today to discuss how our equipment can empower your craft and streamline your operations.

Visual Guide

Related Products

- Fully Automatic Beeswax Embossing Machine Foundation Mill

- Beeswax Machine Press Embosser Wax Foundation Mold Printer Bee Hive Equipment Making Sheet

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

People Also Ask

- What is the application of a silicone beeswax foundation embossing machine? Boost Productivity with Precision Molding

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What is the role of a comb foundation embossing machine? Boost Apiary Productivity with Precision Equipment

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease