At its core, an automatic filling valve is a specialized pressure-reducing valve designed for closed-loop hydronic heating or cooling systems. Its sole function is to maintain a minimum water pressure within the system, automatically adding more water—known as makeup water—whenever the pressure drops below a pre-set level. This ensures the system operates correctly and protects key components from damage.

This small, automated component acts as a safeguard for your entire hydronic system. It eliminates the need for manual "topping off" and ensures the system's pressure never falls to a level that could impair performance or cause damage.

How an Automatic Filling Valve Works

An automatic filling valve, often called a "feed valve" or "makeup water regulator," is a simple yet critical device that connects the domestic water supply to your closed-loop hydronic system.

A Specialized Pressure Regulator

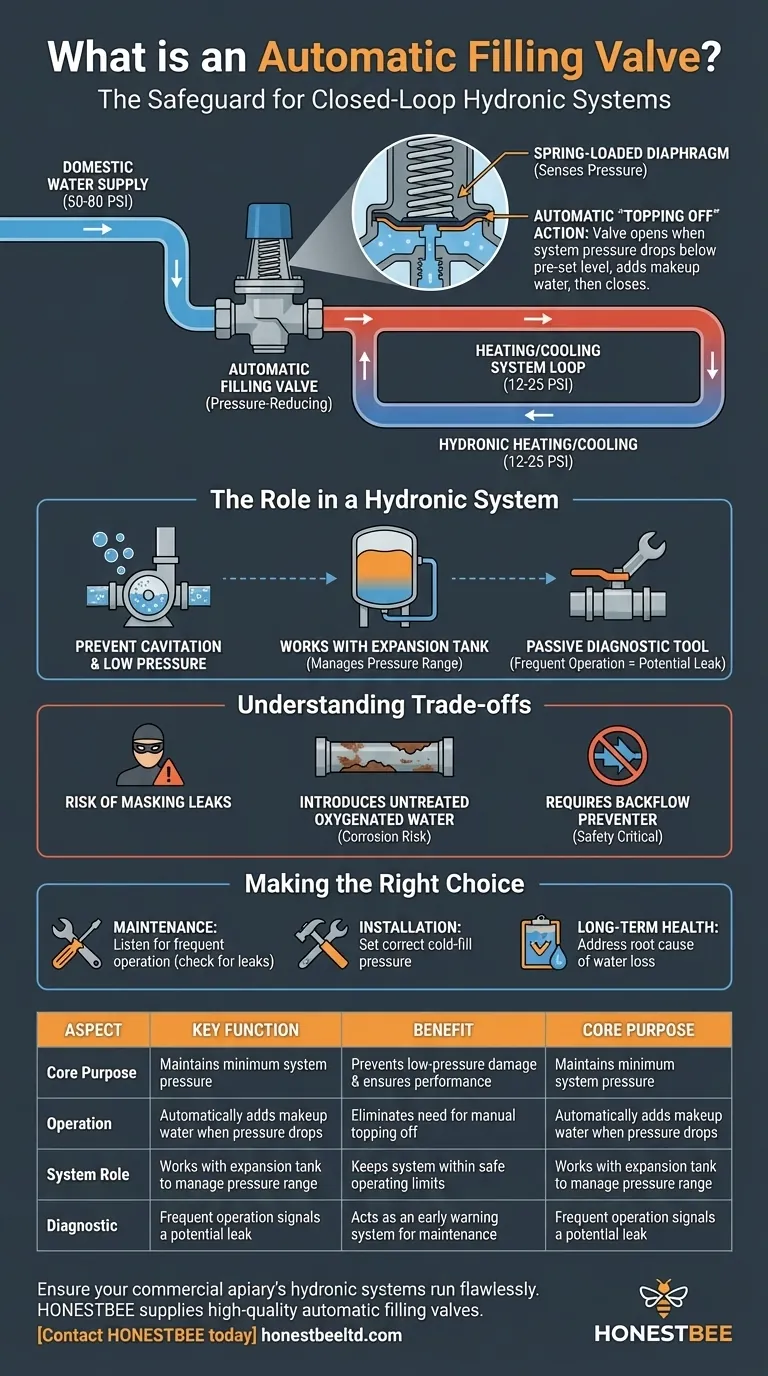

The valve's primary job is to act as a gatekeeper between two different pressure zones. It takes the high-pressure water from your home's main supply (typically 50-80 PSI) and steps it down to the low pressure required by a boiler or chiller system (usually 12-25 PSI).

The Core Mechanism: Pressure Sensing

Inside the valve, a spring-loaded diaphragm constantly senses the pressure on the hydronic system side. This internal mechanism is calibrated to a specific set point, such as 15 PSI.

As long as the system pressure is at or above this set point, the diaphragm keeps the valve sealed shut.

The Automatic "Topping Off" Action

If the system pressure drops below the set point—due to a small leak, air being bled from a radiator, or normal temperature changes—the internal spring expands. This opens the valve, allowing higher-pressure domestic water to flow into the hydronic loop.

Once the system pressure builds back up to the set point, it pushes against the diaphragm, compressing the spring and closing the valve again. This cycle is entirely mechanical and automatic.

The Role in a Hydronic System

The filling valve doesn't work in isolation. It is a key player in a team of components that manage system pressure and function.

Preventing Low-Pressure Conditions

Low pressure is detrimental to a hydronic system. It can lead to air being drawn into the piping, cause the circulator pumps to cavitate (form damaging vapor bubbles), and prevent hot or cold water from reaching the highest points in the building, resulting in poor performance. The auto-fill valve is the first line of defense against this.

Working with the Expansion Tank

The filling valve and the expansion tank work as a pair to manage the system's pressure.

- The automatic filling valve sets the minimum static pressure of the system when the water is cold.

- The expansion tank absorbs the pressure increase that occurs when the system water is heated and expands in volume.

Together, they keep the system pressure within a safe and effective operating range at all times.

A Passive Diagnostic Tool

While its main job is to fill, the valve also serves as an important diagnostic tool. If you can hear the valve operating frequently, it is a clear signal that the system is losing water somewhere. This alerts you to a potential leak that requires investigation.

Understanding the Trade-offs

While essential, the automatic nature of the valve introduces a few considerations that professionals must be aware of.

Risk of Masking Leaks

The valve's primary benefit is also its biggest trade-off. By automatically refilling the system, it can mask a small, slow leak. Without regular inspection, such a leak could go unnoticed for a long time, potentially causing water damage to surrounding structures.

Introducing Untreated Water

Every time the valve adds makeup water, it introduces fresh, oxygen-rich domestic water into the closed loop. This oxygen can accelerate corrosion of iron and steel components like the boiler, pipes, and radiators. For this reason, a filling valve that runs frequently is a significant concern for the long-term health of the system.

The Importance of Backflow Prevention

Because the valve creates a connection between the heating system water and the potable drinking water supply, it is critical to install a backflow preventer. This safety device ensures that contaminated system water can never flow backward and contaminate the clean water supply.

Making the Right Choice for Your Goal

Understanding this component's function is key to maintaining a healthy, efficient hydronic system.

- If your primary focus is system maintenance: Listen for the valve's operation. If you hear it running regularly, it is time to perform a thorough inspection for leaks in your system.

- If your primary focus is proper installation: Ensure the valve is set to the correct cold-fill pressure for your building. A common rule is 0.5 PSI per foot of elevation from the valve to the highest point in the system, plus 3-5 PSI.

- If your primary focus is long-term health: Recognize that frequent refilling is detrimental. Addressing the root cause of water loss is always preferable to relying on the auto-fill valve as a permanent solution.

This simple valve plays a vital role in ensuring your entire heating or cooling system operates reliably and efficiently.

Summary Table:

| Aspect | Key Function | Benefit |

|---|---|---|

| Core Purpose | Maintains minimum system pressure | Prevents low-pressure damage & ensures performance |

| Operation | Automatically adds makeup water when pressure drops | Eliminates need for manual topping off |

| System Role | Works with expansion tank to manage pressure range | Keeps system within safe operating limits |

| Diagnostic | Frequent operation signals a potential leak | Acts as an early warning system for maintenance |

Ensure your commercial apiary's hydronic systems run flawlessly. HONESTBEE supplies the high-quality, reliable automatic filling valves and other essential beekeeping equipment that commercial apiaries and distributors need to protect their investments. Our wholesale-focused operations ensure you get the right components for robust system performance. Contact HONESTBEE today to discuss your equipment needs and keep your operations running smoothly.

Visual Guide

Related Products

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- 50 Hole Standard Design Lip Balm Filling Tray

- Wooden Queen Bee Excluder for Beekeeping

- Professional Drop-Style Hive Handles for Beekeeping

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

People Also Ask

- What are the advantages of using a honey gate? Achieve Clean, Efficient Honey Bottling

- How is the flow of honey controlled using a honey gate valve? Master Precise Bottling and Extraction Techniques

- What are the design advantages of a knife-type honey gate valve? Stop Drips and Improve Extraction Efficiency

- Why is the honey gate important in beekeeping? Ensure Quality & Efficiency in Your Harvest

- What is the proper procedure for cleaning and maintaining a honey gate? Prolong Your Equipment's Life