In essence, a honey gate is a specialized valve designed for beekeeping equipment. It is installed at the bottom of containers like honey extractors or bottling buckets to give the beekeeper precise control over the flow of thick, viscous honey.

A honey gate is more than just a tap; it is the critical control point that transforms honey harvesting from a sticky, chaotic process into a clean, efficient, and manageable task. Its design is purpose-built to handle the unique properties of honey.

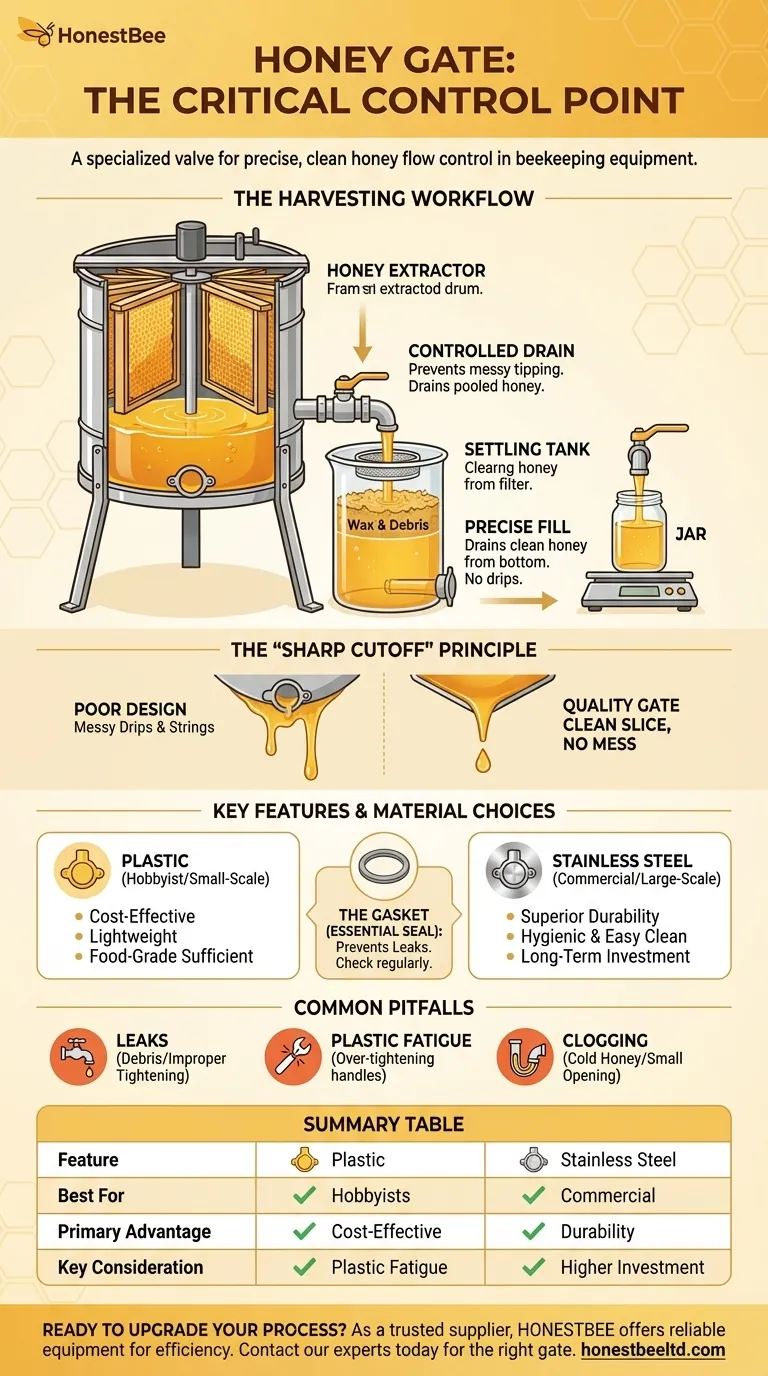

The Role of the Honey Gate in the Harvesting Workflow

While it seems like a simple component, the honey gate serves distinct and vital functions at different stages of processing honey. Understanding where it fits in reveals its importance.

In Honey Extractors

After frames are spun in an extractor, a large volume of honey pools at the bottom of the drum. The honey gate allows the beekeeper to drain this collected honey into a filter and settling tank in a controlled manner.

Without a gate, this transfer would be incredibly difficult and messy, involving tipping a heavy, honey-coated machine.

In Settling Tanks and Bottling Buckets

This is the most common and critical use case. After extraction, honey is often left in a food-grade bucket or tank to "settle," allowing air bubbles and fine wax particles to rise to the top.

The honey gate, positioned at the very bottom, lets you drain the clean, clarified honey from below the layer of debris. It provides the precise on/off control needed to fill individual jars without drips or spills.

The "Sharp Cutoff" Principle

A key feature of a well-designed honey gate is its ability to provide a "sharp cutoff." Because honey is so thick, a poorly designed valve will leave a long, dripping string of honey when closed.

Quality gates are engineered to slice cleanly through the stream, minimizing mess and ensuring accurate fills into jars.

Key Features and Material Choices

Not all honey gates are created equal. The material and design directly impact durability, hygiene, and ease of use.

Plastic Honey Gates

These are the most common type for hobbyist and small-scale beekeepers. They are inexpensive and lightweight. A high-quality plastic gate made from food-grade material is perfectly sufficient for many operations.

Stainless Steel Honey Gates

Favored by semi-commercial and serious beekeepers, stainless steel gates are exceptionally durable, easier to clean and sanitize, and will not become brittle over time. Though more expensive, they are a long-term investment.

The Importance of the Gasket

Regardless of material, the gate's effectiveness depends on its seal. A quality rubber O-ring or gasket is essential to create a leak-proof connection with the bucket or tank. This is the most common point of failure.

Understanding the Trade-offs and Common Pitfalls

While indispensable, honey gates can also be a source of frustration if not chosen or maintained properly.

Leaks and Drips

The most frequent complaint is a slow leak or drip. This is almost always caused by either an improperly tightened gate or a small piece of wax or debris preventing the valve from closing completely.

Plastic Fatigue

The handles on plastic gates can be a weak point. Over-tightening the thumbscrew that secures the valve can stress the plastic, leading to cracks or breakage over time.

Flow Rate and Clogging

Honey that is cold or has started to crystallize can flow very slowly. A gate with a larger diameter opening is better suited for bottling cooler or thicker honey and is less likely to clog with small wax particles.

Making the Right Choice for Your Operation

Selecting a honey gate depends entirely on the scale of your beekeeping and your primary goal.

- If your primary focus is hobby-level bottling: A well-made, food-grade plastic honey gate installed on a 5-gallon bucket is the most practical and cost-effective solution.

- If your primary focus is durability and hygiene for a larger operation: Investing in a stainless steel gate for your main bottling tank is a wise choice that will last for decades.

- If your primary focus is bottling speed and efficiency: Prioritize a gate with a large opening and a proven "sharp cutoff" design to minimize cleanup and maximize your workflow.

Ultimately, the right honey gate transforms a potentially sticky mess into a controlled and satisfying final step in your beekeeping journey.

Summary Table:

| Feature | Plastic Honey Gate | Stainless Steel Honey Gate |

|---|---|---|

| Best For | Hobbyists & Small-Scale Operations | Semi-Commercial & Large-Scale Operations |

| Primary Advantage | Cost-Effective & Lightweight | Superior Durability & Hygiene |

| Key Consideration | Potential for Plastic Fatigue | Higher Initial Investment |

Ready to Upgrade Your Honey Harvesting Process?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the critical role reliable equipment plays in your operation's efficiency and profitability. A quality honey gate is an investment in a cleaner, faster, and more controlled bottling process.

Let us help you select the right honey gate—whether durable plastic or commercial-grade stainless steel—for your specific needs. Contact our experts today to discuss your requirements and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- Stainless Steel Honey Gate Valve Tap Tool for Honey Extractor

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- Premium Diamond-Faceted Glass Honey Dispenser

- Honeycomb Style Drip Free Honey Dispenser

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

People Also Ask

- Can a honey gate be reused, and how should it be stored? Ensure Longevity for Your Honey Harvests

- Under what conditions should the honey gate be closed? Prevent Messy Spills and Ensure Extraction Efficiency

- How do you adjust the flow of honey using a honey gate valve? Master Precision Control for Your Bottling Line

- How is the flow of honey controlled using a honey gate valve? Master Precise Bottling and Extraction Techniques

- What is a honey gate and how is it used in beekeeping equipment? Essential Tools for Precise Honey Bottling