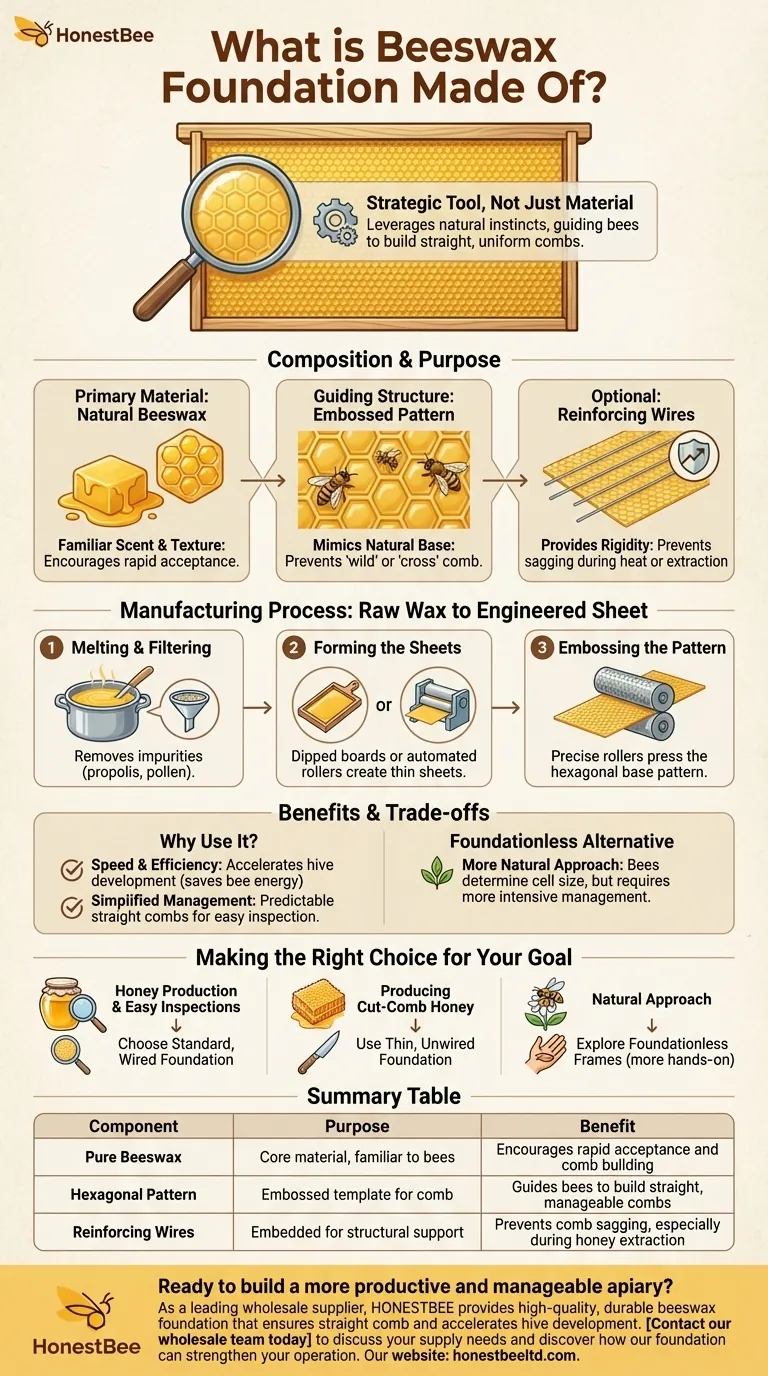

At its core, beeswax foundation is a thin sheet of pure, filtered beeswax that has been imprinted, or embossed, with the hexagonal pattern of a honeycomb. This sheet serves as a guide, providing the bees with a pre-formed base structure upon which they can build out their wax comb for storing honey and raising brood.

The crucial insight is that beeswax foundation is not just a material, but a strategic tool. It leverages the bees' natural instincts by providing a familiar, beeswax-based template, guiding them to build straight, uniform combs that make hive inspections and honey harvesting dramatically more efficient for the beekeeper.

The Composition and Purpose of Foundation

Beeswax foundation is deceptively simple. Its effectiveness comes from combining a natural material with a precise, functional design that encourages predictable behavior from the colony.

The Primary Material: Natural Beeswax

The foundation is made almost entirely from natural beeswax. This is a critical feature, as the wax is a substance bees produce themselves.

Using real beeswax ensures the foundation has a familiar scent and texture that the bees readily accept and begin working on. It's a natural starting point that integrates seamlessly into the hive environment.

The Guiding Structure: The Embossed Pattern

The most important design feature is the embossed hexagonal pattern. This pattern mimics the base of the cells that bees naturally build.

By providing this template, the foundation encourages the bees to build straight combs within the confines of the frame. Without this guide, bees would build "wild" or "cross" comb, connecting multiple frames and making hive inspections nearly impossible without damaging the structure.

Optional Component: Reinforcing Wires

Many sheets of beeswax foundation have crimped wires embedded vertically within the wax. This is not part of the wax itself but a structural addition.

The wire provides rigidity and support, preventing the heavy, wax-laden comb from sagging or breaking, especially in hot weather or during the high-speed spinning of honey extraction.

How Beeswax Foundation is Manufactured

The process transforms raw beeswax into a precisely engineered sheet, whether done by a hobbyist or a large-scale automated machine.

Stage 1: Melting and Filtering

The process begins with raw beeswax, which is melted down. It's essential that the wax is filtered to remove impurities like propolis, pollen, and other hive debris. A clean, pure wax creates a stronger and more appealing foundation.

Stage 2: Forming the Sheets

Once melted and cleaned, the wax is formed into thin, flat sheets. This is typically done in one of two ways.

The traditional method involves dipping wet wooden boards into molten wax repeatedly to build up thin layers. A more modern, automated process uses rollers to press the molten wax into continuous, uniform sheets.

Stage 3: Embossing the Cell Pattern

This is the final, defining step. The flat wax sheet is passed through a set of engraved metal rollers.

These rollers are precisely machined with the hexagonal cell base pattern. As the sheet passes through, the pattern is pressed firmly into both sides of the wax, creating the finished foundation.

Understanding the Trade-offs

While beeswax foundation is a standard beekeeping tool, it's important to understand the strategic choices it represents.

Benefit: Speed and Efficiency

Giving bees a foundation saves them a tremendous amount of energy and resources. They don't have to produce as much wax to create the base of the comb, allowing them to accelerate hive development and focus more on foraging and raising brood.

Benefit: Simplified Hive Management

The primary advantage for the beekeeper is predictability. Straight combs in removable frames allow for easy inspection of the queen, brood, and honey stores. This is fundamental to modern, manageable beekeeping.

The "Foundationless" Alternative

Some beekeepers prefer a more natural approach called foundationless beekeeping. They provide empty frames with only a small starter strip of wood or wax.

This allows bees to build comb with their own naturally-determined cell sizes. However, it requires more intensive management to prevent the bees from building irregular cross comb.

Making the Right Choice for Your Goal

The type of foundation you use, or whether you use it at all, depends entirely on your beekeeping objectives.

- If your primary focus is honey production and easy hive inspections: Choose standard, wired beeswax foundation for its strength and efficiency.

- If your primary focus is producing cut-comb honey: Use thin, unwired foundation, as you don't want wires embedded in the final product.

- If your primary focus is a more natural approach to beekeeping: You might explore foundationless frames, but be prepared for more hands-on hive management.

Ultimately, beeswax foundation is a powerful tool that allows you to work in partnership with your bees, guiding their efforts to build a productive and healthy hive.

Summary Table:

| Component | Purpose | Benefit |

|---|---|---|

| Pure Beeswax | Core material, familiar to bees | Encourages rapid acceptance and comb building |

| Hexagonal Pattern | Embossed template for comb | Guides bees to build straight, manageable combs |

| Reinforcing Wires | Embedded for structural support | Prevents comb sagging, especially during honey extraction |

Ready to build a more productive and manageable apiary?

As a leading wholesale supplier, HONESTBEE provides commercial apiaries and beekeeping equipment distributors with high-quality, durable beeswax foundation that ensures straight comb and simplifies hive management. Our products are designed to save your bees energy and accelerate hive development, directly impacting your bottom line.

Contact our wholesale team today to discuss your supply needs and discover how our foundation can strengthen your operation.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What is the purpose of installing wax foundations in beeswax studies? Ensure Scientific Accuracy and Data Integrity

- What is the recommended practice for arranging different foundation types within a single hive? Achieve Uniform Combs

- What is the significance of using high-purity natural beeswax consumables for hive foundations? Boost Hive Health

- What role does a standard comb foundation play in measuring beeswax productivity? Quantify Your Colony's Wax Output

- Why is the regular replacement of foundation wax necessary? Boost Hive Health and Honey Production

- What are the long-term storage requirements for processed beeswax? Expert Tips for Indefinite Preservation

- What is the significance of honeycomb wax caps in sunflower honey harvesting? Ensure Maturity & Quality Control

- How does the regular provision of high-quality beeswax foundation impact environmental pollution risk management?