At its core, honey processing is the act of removing honey from the waxy comb and preparing it for consumption. This involves a series of steps designed to separate the pure honey from impurities like beeswax, pollen, and other debris collected from the hive. The primary stages include extraction, filtration, and finally, packaging into containers.

The fundamental goal of honey processing is to produce a clean, stable, and consistent product. The key variables in this process are the degree of filtration and the application of heat, which determine whether the final product retains its raw, natural state or is refined for a clearer appearance and longer shelf life.

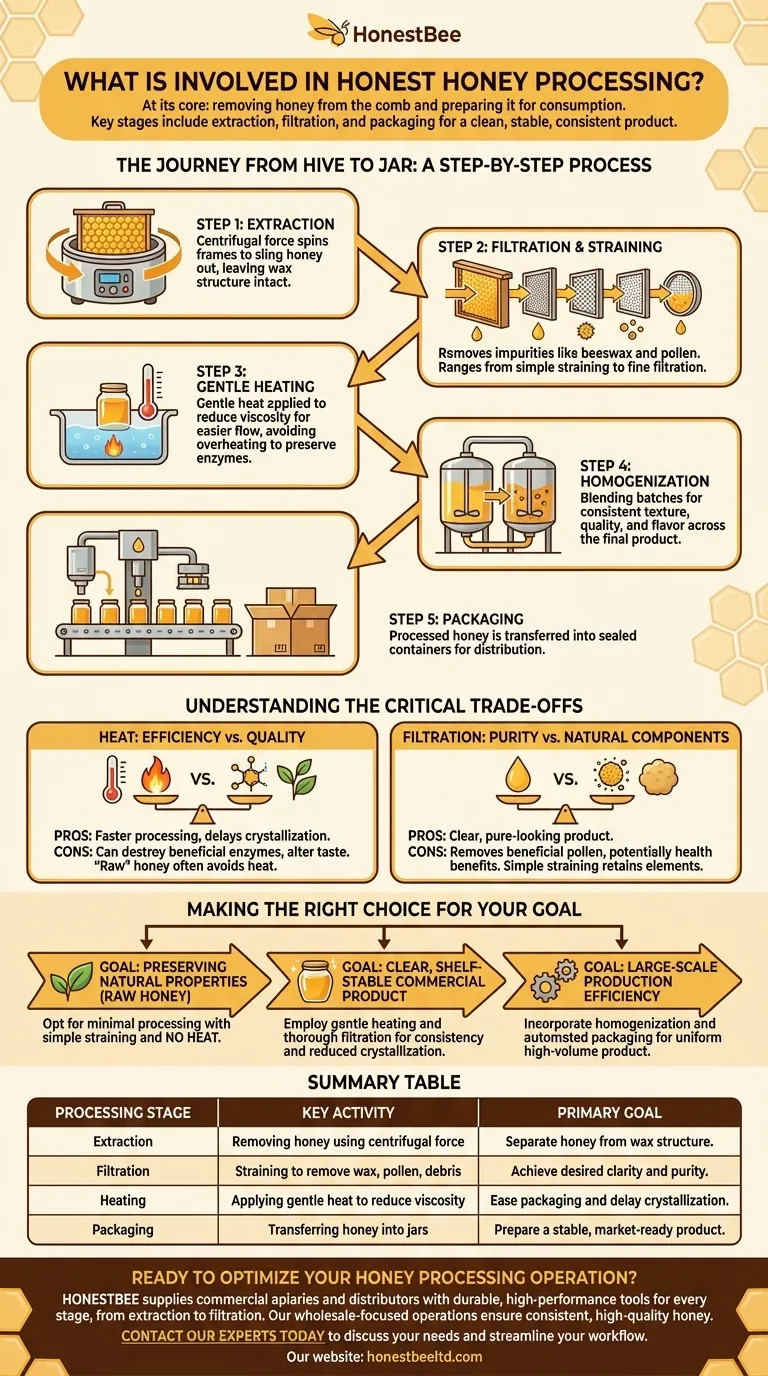

The Journey from Hive to Jar: A Step-by-Step Process

Understanding the journey honey takes reveals the purpose behind each stage. The process ensures the final product is pure, safe, and has a desirable consistency for the consumer.

Step 1: Extraction

The first major step is to get the honey out of the honeycomb. Beekeepers uncap the wax cells and place the frames into a honey extractor.

This machine uses centrifugal force, spinning the frames at high speeds to sling the honey out of the comb while leaving the wax structure intact.

Step 2: Filtration and Straining

Once extracted, the raw honey contains various particles. Filtration is the critical step for removing visible impurities.

This can range from simple straining to remove large pieces of beeswax to finer filtration that removes smaller particles like pollen.

Step 3: Gentle Heating

Honey is naturally thick, or viscous. To make it flow more easily for filtration and packaging, processors often apply gentle heat.

This is typically done in a controlled manner, like a water bath, to avoid overheating the honey, which could degrade its natural enzymes and delicate flavors.

Step 4: Homogenization

In larger commercial operations, honey from different batches may be blended together in a process called homogenization.

This ensures that every jar has a consistent texture, quality, and flavor, providing a uniform product for the market.

Step 5: Packaging

The final step is packaging. The processed honey is transferred into jars or other containers, sealed, and labeled for distribution and sale. Automated systems are often used to maximize efficiency.

Understanding the Critical Trade-offs

The methods used during processing create significant differences in the final product. The two most important decisions revolve around heat and filtration.

The Role of Heat: Efficiency vs. Quality

Applying heat makes honey much easier and faster to process. It also delays crystallization, the natural process where honey solidifies.

However, excessive heat can destroy beneficial enzymes and alter the honey's subtle taste profile. This is why "raw" honey producers often avoid heat entirely.

The Degree of Filtration: Purity vs. Natural Components

Fine filtration creates a brilliantly clear, pure-looking product that many consumers expect. It effectively removes all suspended particles.

The downside is that this process can also remove beneficial components like pollen, which contributes to the honey's unique character and potential health benefits. Simple straining, by contrast, leaves these elements in but may result in a cloudier appearance.

Making the Right Choice for Your Goal

The ideal processing method depends entirely on the desired outcome for the final product.

- If your primary focus is preserving natural properties (Raw Honey): Opt for minimal processing with simple straining and absolutely no heat.

- If your primary focus is a clear, shelf-stable commercial product: Employ gentle heating and a thorough filtration system to ensure consistency and prevent crystallization.

- If your primary focus is large-scale production efficiency: Incorporate homogenization and automated packaging to create a uniform product at scale.

Understanding these steps empowers you to make an informed choice, whether you are producing honey or simply selecting a jar from the shelf.

Summary Table:

| Processing Stage | Key Activity | Primary Goal |

|---|---|---|

| Extraction | Removing honey from comb using centrifugal force. | Separate honey from the wax structure. |

| Filtration | Straining to remove wax, pollen, and debris. | Achieve desired clarity and purity. |

| Heating | Applying gentle heat to reduce viscosity. | Ease packaging and delay crystallization. |

| Packaging | Transferring honey into jars for sale. | Prepare a stable, market-ready product. |

Ready to optimize your honey processing operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-performance tools needed for every stage—from efficient honey extractors to precise filtration systems. Our wholesale-focused operations ensure you get the reliable equipment required to produce consistent, high-quality honey, whether your goal is raw artisanal batches or large-scale commercial production.

Contact our experts today to discuss your specific needs and streamline your workflow from hive to jar.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- What size honey extractor do I need? Match Frame Capacity to Your Hives for Maximum Efficiency

- What is the pressing method for extracting honey? A Simple, Low-Cost Approach for Small-Scale Beekeepers