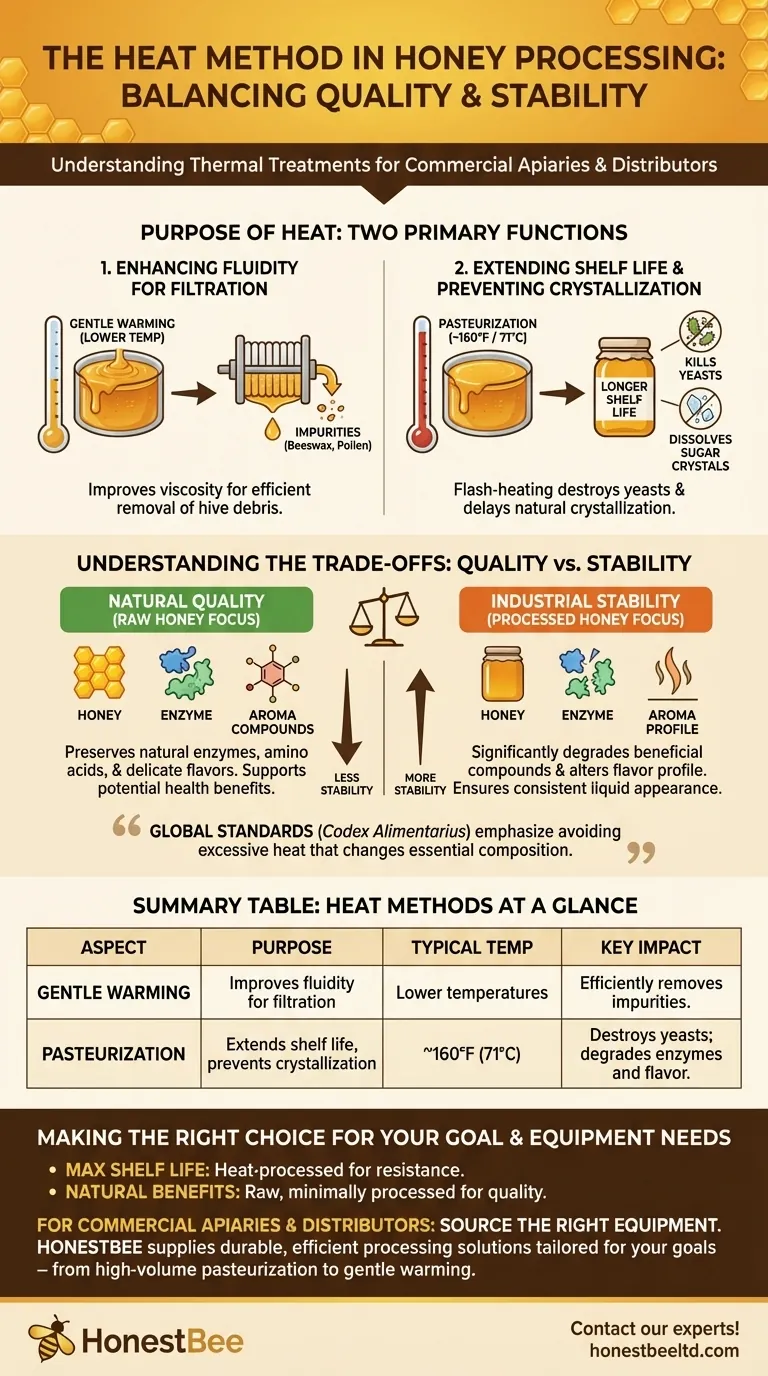

In honey processing, the "heat method" refers to the application of thermal treatment to achieve specific outcomes. This typically involves gently warming the honey to improve its fluidity for filtering or heating it to higher temperatures (pasteurization) to destroy yeasts, dissolve sugar crystals, and extend its shelf life.

The central trade-off of heating honey is clear: it creates a product with a longer shelf life and a consistently clear, liquid appearance, but this often comes at the cost of diminishing the honey's natural enzymes, delicate flavors, and beneficial compounds.

The Purpose of Heat in Honey Processing

Applying heat serves two primary functions in the commercial processing of honey. The intensity of the heat determines the final characteristics of the product.

Enhancing Fluidity for Filtration

Honey is naturally viscous, or thick. Gently warming it lowers this viscosity, making it flow much more easily.

This improved fluidity is critical for the filtration step, where impurities like beeswax, pollen, and other hive debris are removed. Without gentle warming, this process would be extremely slow and inefficient.

Extending Shelf Life and Preventing Crystallization

A more intensive heat treatment, known as pasteurization, is used to dramatically extend shelf life. This is often a "flash-heating" process.

Heating honey to approximately 160°F (about 71°C) kills wild yeasts that can cause the honey to ferment over time. This process also dissolves tiny sugar crystal "nuclei," which significantly delays the natural process of crystallization and keeps the honey liquid on the shelf for much longer.

Understanding the Trade-offs

While heat provides clear benefits for commercial production and stability, these advantages come with significant compromises to the honey's natural quality.

Degradation of Beneficial Compounds

The most significant downside of high-heat processing is the destruction of natural components. Heat can denature enzymes and amino acids that are inherent to raw honey.

These compounds are believed to be responsible for many of honey's health benefits, so pasteurized honey is often considered nutritionally inferior to its raw counterpart.

Alteration of Flavor and Aroma

Overheating can fundamentally change the delicate and unique flavor profile of honey. The complex aromatic compounds that give different honey varietals their distinct tastes can be diminished or destroyed by high temperatures.

This results in a more uniform, but less nuanced, flavor.

International Quality Standards

It's important to note that global standards, such as the Codex Alimentarius, explicitly state that honey should not be heated to a degree that its essential composition is changed or its quality is significantly impaired.

This highlights the global recognition that excessive heat damages the fundamental nature of the product.

Making the Right Choice for Your Goal

Understanding the impact of heat allows you to select honey based on your specific priorities.

- If your primary focus is maximum shelf life and consistent clarity: Heat-processed or pasteurized honey is the most reliable option, as it is designed to resist crystallization and fermentation.

- If your primary focus is preserving natural health benefits and flavor: Seek out "raw" or minimally processed honey that has not been subjected to high-heat pasteurization.

Ultimately, choosing your honey wisely means knowing whether you value industrial stability or the preservation of natural quality.

Summary Table:

| Aspect | Purpose | Typical Temperature | Key Impact |

|---|---|---|---|

| Gentle Warming | Improves fluidity for filtration | Lower temperatures | Efficiently removes impurities like beeswax and pollen. |

| Pasteurization | Extends shelf life, prevents crystallization | ~160°F (71°C) | Destroys yeasts, dissolves sugar crystals; degrades enzymes and flavor. |

For Commercial Apiaries & Distributors: Source the Right Equipment for Your Honey Processing Needs

Whether your focus is on high-volume pasteurization for extended shelf life or gentle warming to preserve the qualities of raw honey, having the right equipment is crucial. HONESTBEE supplies durable, efficient beekeeping supplies and processing equipment tailored for commercial apiaries and beekeeping equipment distributors.

We help you achieve your production goals, whether that's industrial stability or preserving natural quality. Let's discuss your specific needs and how our wholesale-focused operations can support your business.

Contact our experts today to find the perfect solution!

Visual Guide

Related Products

- HONESTBEE Commercial Upright Honey Melter

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- How to fix solidified honey? A Beekeeper's Guide to Gentle Re-liquefaction

- What is heat treatment for honey? A Guide to Liquefying, Pasteurizing, and Preserving Quality

- What are the methods for heating honey? Preserve Quality and Improve Workability

- Why is a honey bucket warmer considered a valuable tool for honey storage? Preserve Quality & Streamline Bottling

- What are the key features to look for in a honey warming source? Preserve Honey Quality with Gentle, Even Heat