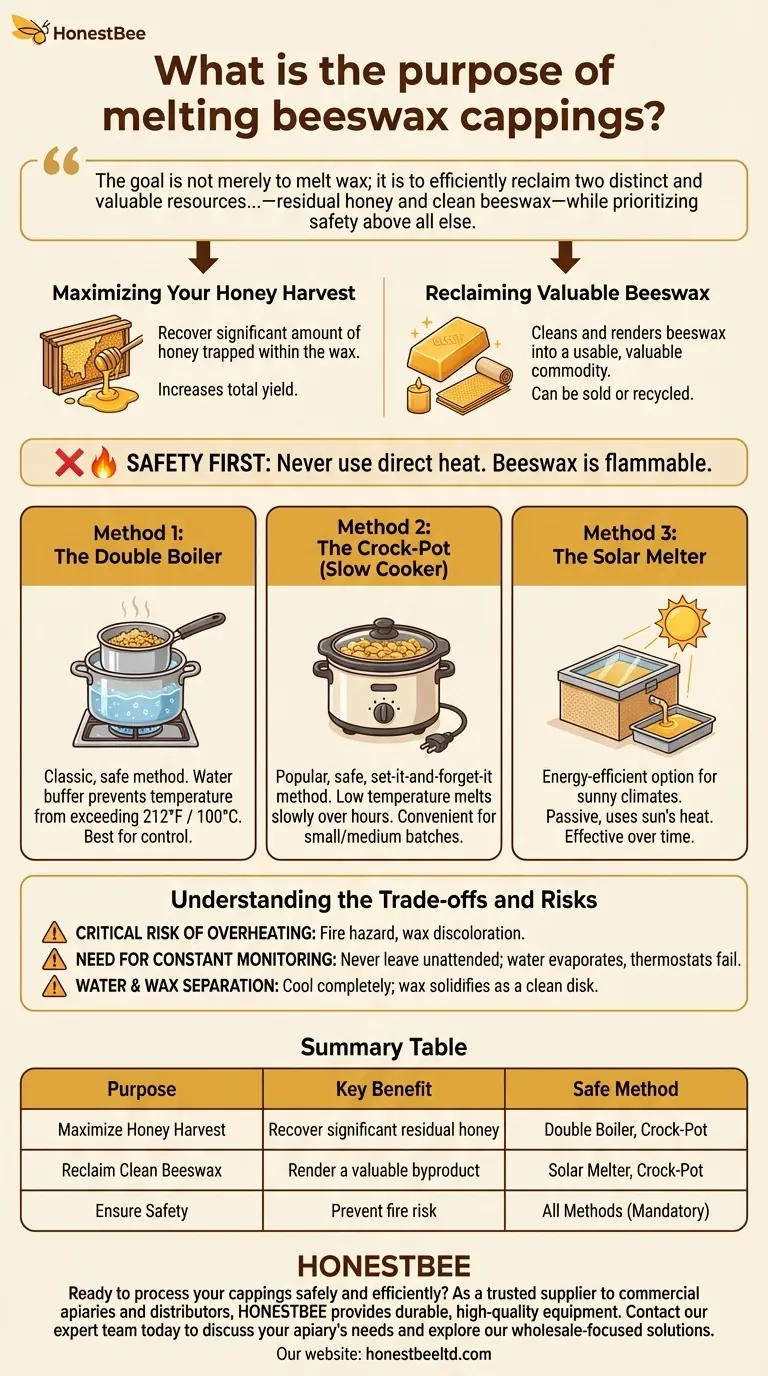

At its core, melting beeswax cappings serves two primary functions for a beekeeper. First, it allows you to separate and recover the significant amount of honey still trapped within the wax, maximizing your harvest. Second, it cleans and renders the beeswax into a usable block, a valuable byproduct that can be sold or recycled.

The goal is not merely to melt wax; it is to efficiently reclaim two distinct and valuable resources from the honey harvest—residual honey and clean beeswax—while prioritizing safety above all else.

The Dual Goals of Rendering Cappings

When you uncap frames of honey, the resulting mixture of wax and honey is a valuable asset. Processing it correctly ensures nothing goes to waste.

Maximizing Your Honey Harvest

Cappings removed from honeycomb are saturated with honey. Simply letting them drain is inefficient and leaves a large percentage of honey behind.

By gently melting the cappings, the less dense wax separates and floats to the top, allowing the heavier honey to settle below for easy collection. This step can noticeably increase your total honey yield.

Reclaiming Valuable Beeswax

The separated wax is a valuable commodity. Once it has been rendered and cleaned of honey and other impurities, it can be used for many purposes.

Beekeepers often recycle this wax to create new foundation sheets for their hive frames. It is also highly sought after for making candles, cosmetics, and wood polishes.

How to Safely Melt Beeswax

The single most important rule when melting beeswax is to never use direct heat. Beeswax is flammable and has a low flashpoint, meaning it can ignite if overheated. Always use an indirect heating method.

The Principle of Indirect Heat

Indirect heat uses a medium, typically water or air, to gently and evenly warm the wax. This prevents hot spots, scorching, and dangerous temperature spikes that could lead to a fire.

Method 1: The Double Boiler

A double boiler is the classic method for safely melting wax. You place a smaller pot containing the wax inside a larger pot of simmering water.

The water acts as a buffer, ensuring the wax temperature cannot exceed the boiling point of water (212°F / 100°C), which is well below its danger point.

Method 2: The Crock-Pot (Slow Cooker)

Using a crock-pot or slow cooker is another popular and safe method. The cappings are placed directly into the pot, often with some water.

Set to a low temperature, the crock-pot melts the wax and honey slowly over several hours, allowing for a clean separation as it cools.

Method 3: The Solar Melter

For beekeepers in sunny climates, a solar melter is an energy-efficient option. This is typically an insulated box with a glass lid that uses the sun's heat to melt the cappings.

The melted wax and honey run down a collection pan, separating naturally. This is a passive and effective method for processing wax over time.

Understanding the Trade-offs and Risks

While the process is straightforward, awareness of the risks is critical for a safe and successful outcome.

The Critical Risk of Overheating

Again, never place a pot of wax directly on a stove burner or open flame. This can quickly overheat the wax, discoloring it and creating a serious fire hazard. Always monitor the process.

The Need for Constant Monitoring

Never leave melting wax unattended. Even with indirect heat, situations can change. In a double boiler, the water can evaporate, and in a crock-pot, a faulty thermostat could cause overheating.

Water and Wax Separation

When melting cappings with water, the final step is simple. Once melted, turn off the heat and let the mixture cool completely. The wax will solidify into a clean disk on top of the honey-water mixture, which can be lifted off easily.

Making the Right Choice for Your Goal

Your chosen method will depend on your equipment, batch size, and patience. Safety, however, is non-negotiable.

- If your primary focus is ultimate safety and control: Use the double boiler method, as it provides the most reliable temperature regulation.

- If your primary focus is convenience for small-to-medium batches: The crock-pot method is an excellent and widely used "set it and forget it" choice (while still monitoring).

- If your primary focus is energy efficiency and you have ample sun: A solar melter is a fantastic, passive solution for processing cappings throughout the season.

By properly rendering your cappings, you transform a messy byproduct into two valuable streams for your apiary.

Summary Table:

| Purpose | Key Benefit | Safe Method |

|---|---|---|

| Maximize Honey Harvest | Recover significant residual honey from uncapped frames. | Double Boiler, Crock-Pot |

| Reclaim Clean Beeswax | Render a valuable byproduct for foundation, candles, or sale. | Solar Melter, Crock-Pot |

| Ensure Safety | Prevent fire risk by using indirect heat, never direct flame. | All Methods (Mandatory) |

Ready to process your cappings safely and efficiently?

As a trusted supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-quality equipment you need—from wax melters to full harvesting systems. Let us help you maximize the value of every harvest.

Contact our expert team today to discuss your apiary's needs and explore our wholesale-focused solutions.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the primary function of solar or steam wax melters in the initial processing of raw beeswax? Maximize Wax Purity

- What is done with the beeswax cappings after they are removed? Turn Your Hive Byproducts into Gold

- What is the role of industrial steam heating equipment in the recovery and processing of beeswax? Efficiency Explained

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures