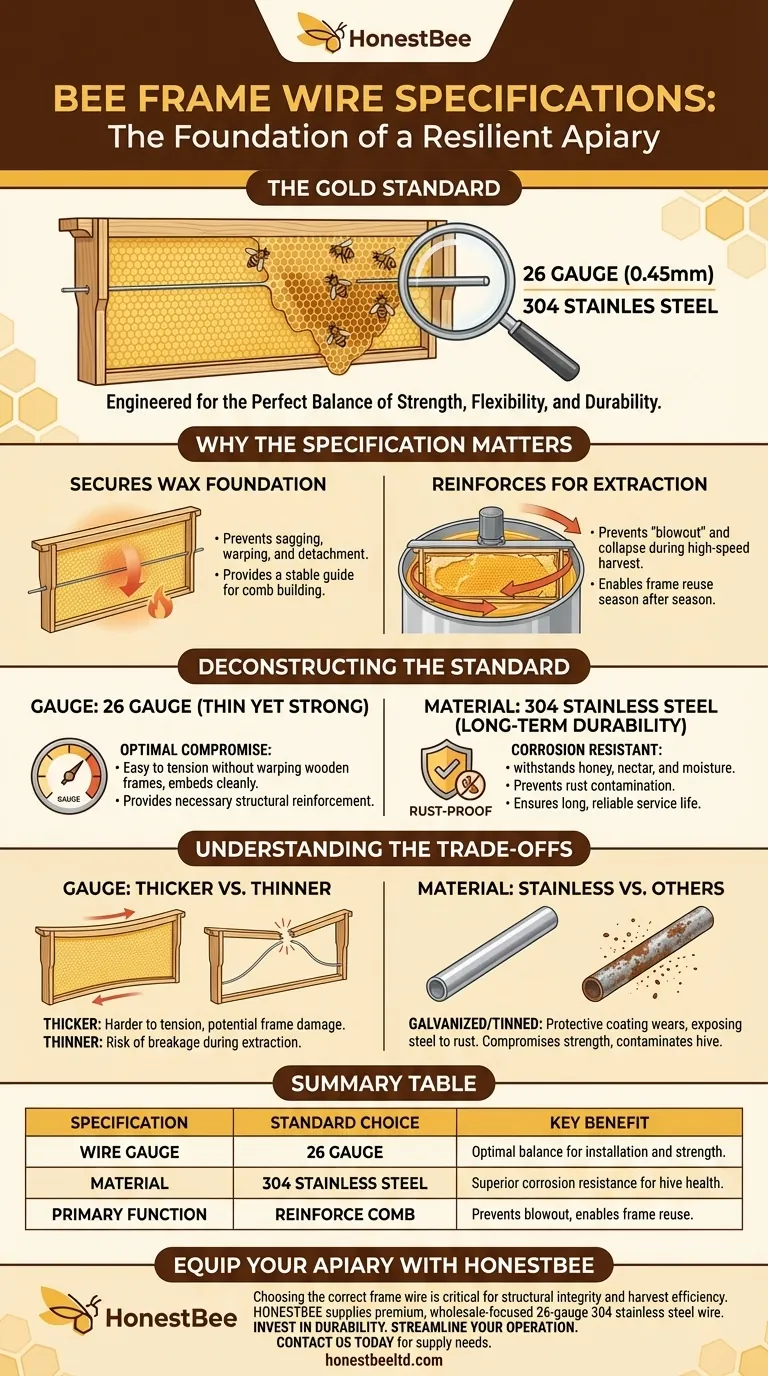

The standard specification for bee frame wire is 26 gauge, typically made from 304 stainless steel. This specific combination is not arbitrary; it is engineered to provide the ideal balance of strength for structural support and flexibility for proper installation, ensuring the long-term integrity of the honeycomb.

The choice of frame wire goes beyond simply holding a sheet of wax. It is a critical decision for creating a durable, reusable frame skeleton that can withstand the immense forces of honey extraction and support the health of the hive for years.

Why the Wire Specification Matters

Understanding the function of frame wire reveals why its specifications are so precise. The wire serves two primary purposes, both of which are critical to efficient and sustainable beekeeping.

Securing the Wax Foundation

The wire acts as an internal scaffold. A sheet of wax foundation is placed against the wires, and a low-voltage electric current is often used to gently heat the wire, causing it to melt slightly and embed into the wax.

This creates a secure bond, giving the bees a stable guide to begin building out their comb. Without this support, the thin wax foundation can sag, warp, or detach.

Reinforcing the Comb for Extraction

This is the most critical function. A frame full of honey is heavy and its wax structure is relatively fragile. During honey harvesting, frames are spun at high speed in a centrifugal extractor.

The wire reinforcement prevents the honeycomb from "blowing out" or collapsing under the intense force. A well-wired frame can be harvested and returned to the hive for reuse season after season.

Deconstructing the Standard: Gauge and Material

The two key technical details of bee frame wire are its gauge (thickness) and its material composition.

The Significance of 26 Gauge

Wire gauge follows an inverse relationship: a higher gauge number means a thinner wire. The 26-gauge standard is the optimal compromise.

It is thin enough to be easily tensioned without warping the wooden frame and to embed cleanly into the wax foundation. At the same time, it is strong enough to provide the necessary structural reinforcement.

The Role of 304 Stainless Steel

While other materials exist, 304 stainless steel is the preferred choice for its durability and safety. It offers excellent resistance to corrosion from honey, nectar, and atmospheric moisture.

This prevents rust from weakening the wire or contaminating the honey and wax, ensuring a long and reliable service life for the frame.

Understanding the Trade-offs

While 26-gauge stainless steel is the standard, understanding why other options are less suitable reinforces the value of this choice.

Thicker vs. Thinner Wire

Using a thicker wire (e.g., 24 gauge) would make it significantly harder to pull taut and could potentially bow or damage the wooden frame under tension. It would also require more heat to embed into the wax.

Conversely, a thinner wire (e.g., 28 gauge) would be easier to handle but might not possess the tensile strength to support a full comb during extraction, risking breakage and loss of the harvest.

Stainless Steel vs. Other Materials

Galvanized or tinned steel wire can be a cheaper alternative, but it presents a significant long-term risk. The protective coating can wear away over time, exposing the steel underneath to rust.

This not only compromises the wire's strength but also introduces rust into the hive environment, which is undesirable for both the bees and the quality of the honey.

Making the Right Choice for Your Frames

Your choice of wire directly impacts the durability of your equipment and the efficiency of your workflow.

- If your primary focus is reliability and best practices: Use the industry standard of 26-gauge 304 stainless steel wire without exception.

- If your primary focus is a long-term, low-maintenance apiary: Prioritize stainless steel over cheaper alternatives to avoid the future labor and cost of rewiring rusty frames.

Choosing the correct frame wire is a foundational investment in building a resilient and productive apiary.

Summary Table:

| Specification | Standard Choice | Key Benefit |

|---|---|---|

| Wire Gauge | 26 Gauge | Optimal balance of strength and flexibility for easy installation. |

| Material | 304 Stainless Steel | Superior corrosion resistance for long-term hive health. |

| Primary Function | Reinforce Comb | Prevents comb blowout during honey extraction, enabling frame reuse. |

Equip your apiary with the right foundation for success.

Choosing the correct frame wire is critical for the structural integrity of your honeycomb and the efficiency of your harvest. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with premium, wholesale-focused beekeeping supplies, including reliable 26-gauge 304 stainless steel frame wire.

Invest in durability and streamline your operation. Contact HONESTBEE today to discuss your supply needs and ensure your frames are built to last.

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Professional Pneumatic Wire Embedder for Beehive Frames

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- HONESTBEE Wooden Bar Copper Prong Wire Embedder for Battery Operation

People Also Ask

- What should be done to the sidebars if wiring the frames? A Guide to Drilling Holes for Maximum Frame Strength

- What feature of the frame wiring jig helps maintain wire tightness? The Essential Tensioner Explained

- What precautions should be taken when wiring beehive frames? Essential Steps for Comb Durability

- What is the purpose of the frame wiring jig? Speed Up Bee Frame Wiring in Under 90 Seconds

- What tools are needed to wire a beehive frame? Essential Equipment for Durable Frame Construction