At its core, a Langstroth hive is more complicated than a top bar hive because it is a modular system designed for active management and scalability. This design involves multiple interchangeable components, requires specialized equipment for honey harvesting, and demands a more hands-on approach to hive inspections and seasonal adjustments.

The choice between a Langstroth and a top bar hive is not just about complexity; it's a decision between two distinct beekeeping philosophies. Langstroth prioritizes high honey yields and scalability through intensive management, while top bar prioritizes simplicity and a more natural, low-intervention approach.

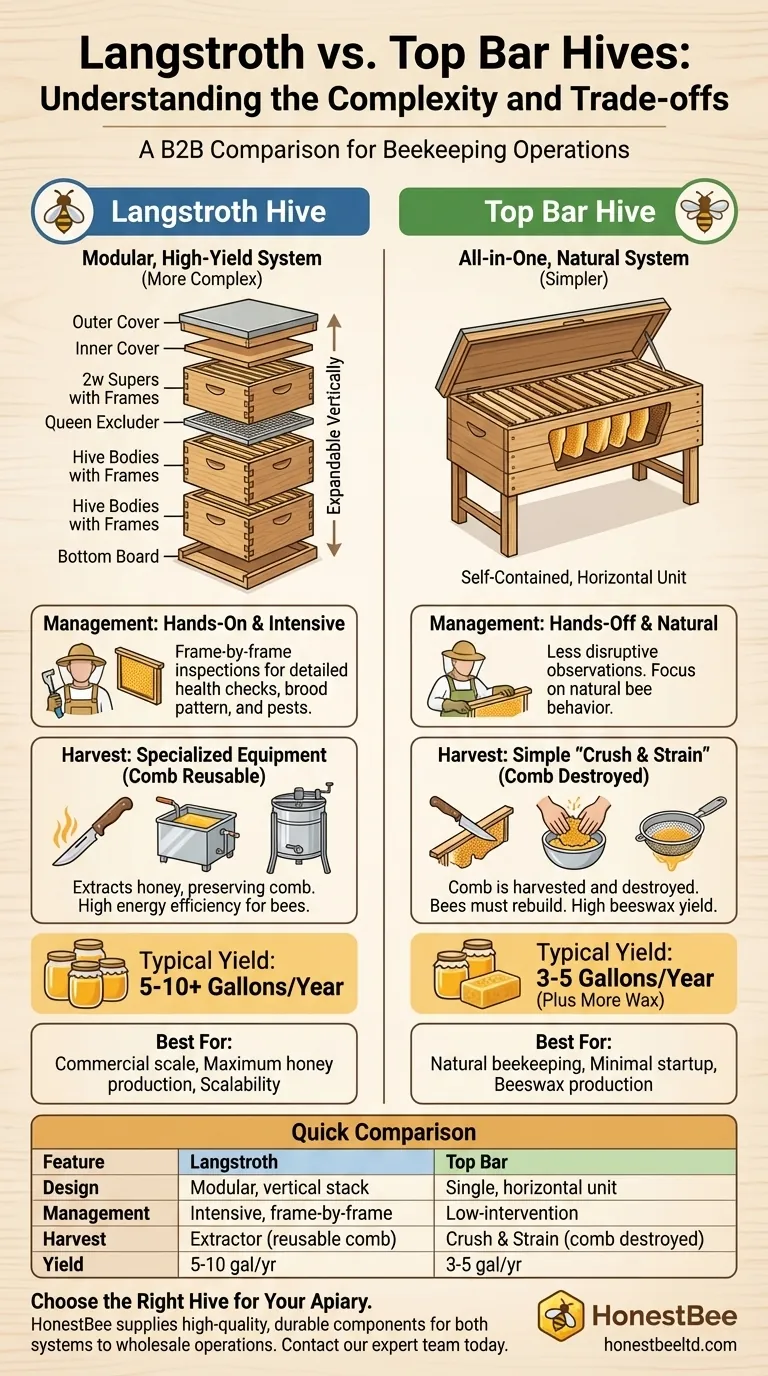

The Core Difference: Modular vs. All-in-One Design

The fundamental source of complexity in a Langstroth hive comes from its construction. It is a system of parts, not a single object.

The Langstroth Hive: A System of Interchangeable Parts

A standard Langstroth hive is a vertical stack of components: a bottom board, multiple hive bodies (deeps and supers), precisely manufactured frames with foundation, an inner cover, and an outer cover.

This modularity allows the beekeeper to expand or contract the hive's size by adding or removing boxes in response to the colony's growth and nectar flow. A queen excluder is often added to control where the queen lays eggs.

The Top Bar Hive: A Self-Contained Unit

In contrast, a top bar hive is a single, horizontal box. It has no frames, foundations, or separate boxes to manage.

The only internal components are simple wooden top bars, often with a starter strip of wood or wax to guide the bees. The hive is a self-contained unit that does not expand vertically.

A Closer Look at Management Demands

The design of each hive directly dictates the level and type of work required from the beekeeper.

Langstroth: Hands-On Frame-by-Frame Inspections

Managing a Langstroth hive is an active process. Inspections involve removing the roof and inner cover, then lifting out individual frames one by one.

Beekeepers must check each frame for the queen's health, the brood pattern, honey and pollen stores, and signs of pests like varroa mites. This detailed access is powerful but also more disruptive to the colony and time-consuming for the beekeeper.

Top Bar: A More Hands-Off Philosophy

Top bar hive management is purposefully less intensive. Inspections involve gently lifting one bar at a time to observe the naturally drawn comb.

The goal is to interfere as little as possible. While checks for pests and colony health are still performed, the overall approach is geared toward letting the bees manage their own space.

Space Management and Expansion

With a Langstroth hive, a key task is space management. Beekeepers must add supers at the right time to give bees room for honey and prevent swarming, then remove them for harvest.

Top bar hives do not expand. The bees simply build comb along the series of bars, and the beekeeper manages the colony's size within the fixed horizontal space.

Understanding the Trade-offs: Harvest and Yield

The greatest difference in complexity appears during honey harvest, which in turn impacts the hive's productivity.

The Langstroth Harvest: Specialized Equipment for Reusable Comb

Harvesting from a Langstroth hive is a multi-step process requiring specialized tools. It involves using a hot knife to uncap the honeycomb, a capping tank to collect the wax, and a centrifugal extractor to spin honey out of the frames.

The major advantage of this complexity is that the comb remains intact. Preserving the comb saves the bees immense energy, allowing them to focus on making more honey.

The Top Bar Harvest: Simple "Crush and Strain"

Harvesting from a top bar hive is far simpler. The beekeeper cuts the entire comb off the top bar, crushes it by hand, and strains the honey through a sieve or cheesecloth. This requires only basic kitchen utensils.

The trade-off is that this method destroys the comb. The bees must expend significant energy and resources to rebuild it from scratch, which reduces the overall honey yield for the season.

The Impact on Production

The Langstroth system's efficiency leads to higher honey yields, typically 5-10 gallons per year. Its standardized, movable design makes it the choice for commercial operations.

The top bar hive's simplicity and the need to rebuild comb result in lower yields, around 3-5 gallons annually. However, the crush-and-strain method produces a much larger quantity of valuable beeswax.

Making the Right Choice for Your Goal

Understanding these complexities allows you to choose the system that aligns with your specific beekeeping objectives.

- If your primary focus is maximizing honey production or commercial viability: The Langstroth hive is the industry standard for its efficiency, scalability, and high-yield potential.

- If your primary focus is natural, low-intervention beekeeping with minimal startup cost: The top bar hive offers a simpler, more bee-centric approach with less equipment and management.

- If your primary focus is generating beeswax alongside honey: The top bar hive's "crush and strain" harvest method will provide a significantly larger wax harvest than a Langstroth hive.

Ultimately, the right hive is the one that best matches your philosophy, your available time, and what you hope to achieve with your bees.

Summary Table:

| Feature | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Design | Modular, vertical stack of boxes | Single, horizontal unit |

| Management | Hands-on, frame-by-frame inspections | Less intensive, low-intervention |

| Harvest Method | Extractor (reusable comb) | Crush and strain (comb destroyed) |

| Typical Honey Yield | 5-10 gallons per year | 3-5 gallons per year |

| Best For | High honey production, scalability | Natural beekeeping, simplicity, beeswax production |

Ready to choose the right hive for your apiary?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable components needed for both Langstroth and top bar hive systems. Whether you're scaling up a commercial operation or seeking reliable equipment for natural beekeeping, our wholesale-focused operations ensure you get the right tools for your philosophy and goals.

Contact our expert team today to discuss your specific needs and discover how HONESTBEE can support your beekeeping success.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- What is the significance of standardized beehives? Achieve Research Precision with Consistent Hive Frame Dimensions

- Why is a single-story 8-frame standard beehive used for indoor overwintering? Maximize Efficiency and Control

- What is the function of a 10-frame wooden beehive with a hygienic bottom board? Optimize Health and Scale Your Apiary

- What are the advantages of standardized backyard beehives for bee temperament? Transition to Gentle Colony Management

- What are the signs that indicate it's time to add a super to a beehive? Prevent Swarming & Maximize Honey Production

- What is the industrial significance of standard Langstroth hives? Bridging Research and Commercial Apiary Success

- What technical advantages do modern movable-frame beehives offer? Unlock Industrial Efficiency & High Honey Yields

- How does the deployment of standardized pollination hardware mitigate the impact of declining wild pollinators?