When using a double boiler for candle making, your most critical precautions are to constantly supervise the melting wax, use heat-resistant gloves, maintain a gap between the water and the upper pot, and clean your equipment thoroughly after use. These steps are fundamental for preventing both personal injury and fire hazards while ensuring the quality of your final candle.

The core principle is control. A double boiler is designed to provide gentle, indirect heat, and your precautions are all aimed at maintaining that control to prevent the wax from reaching its flash point and to ensure a smooth, high-quality melt.

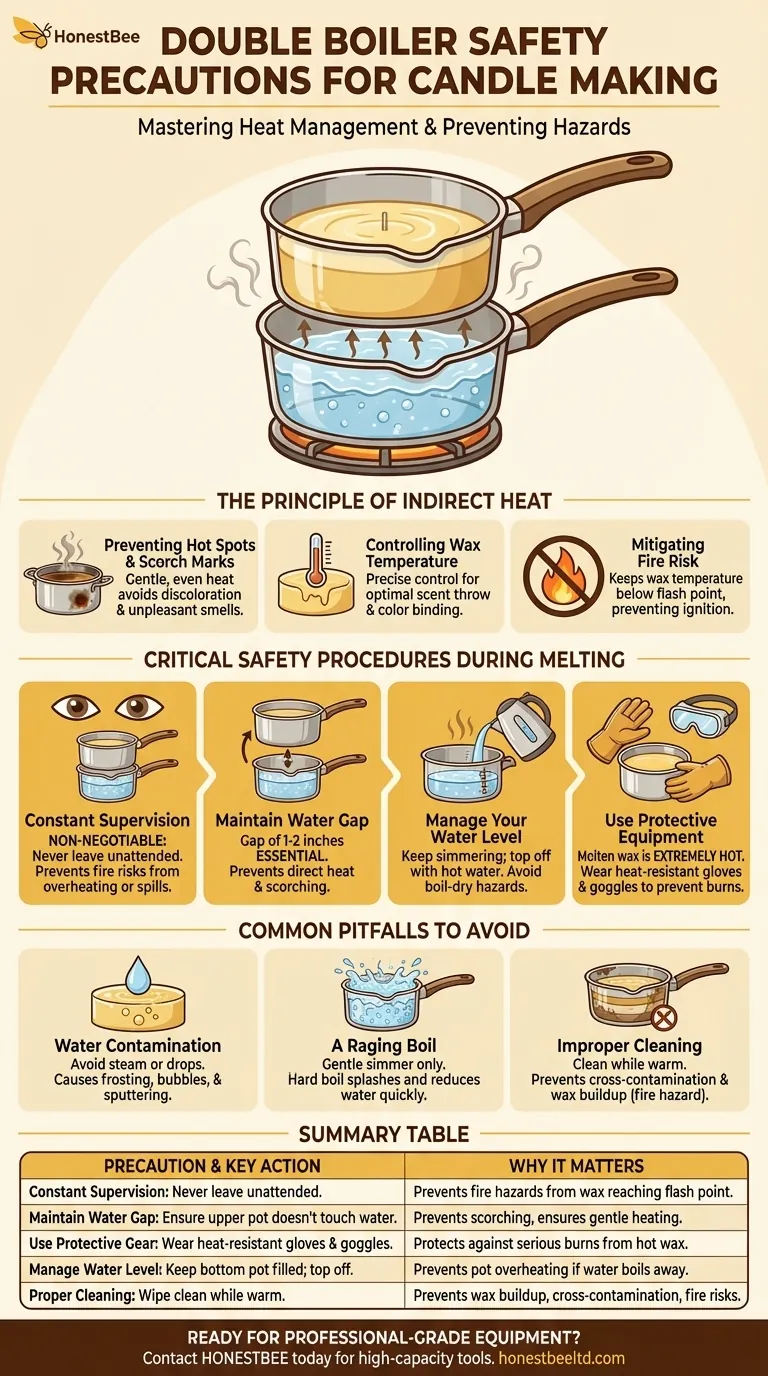

The Principle of Indirect Heat

The entire purpose of a double boiler is to heat a substance gently and evenly, without the harsh, direct heat of a flame or electric burner. Understanding this principle is the key to understanding the safety precautions.

Preventing Hot Spots and Scorch Marks

Direct heat is too aggressive for candle wax. It can easily create "hot spots" that scorch the wax, which can discolor it and create an unpleasant burnt smell that will carry through to your finished candle.

A double boiler uses steam from the simmering water below to gently heat the walls of the upper pot, melting the wax evenly and consistently.

Controlling Wax Temperature

Properly melting wax isn't just about turning a solid into a liquid. The temperature of the wax is critical for correctly binding with fragrance oils and color dyes.

Indirect heat gives you the precise temperature control needed to hit the optimal temperature ranges for adding these elements, leading to a much better scent throw and even color distribution.

Mitigating Fire Risk

Every type of wax has a flash point—the temperature at which its vapors can ignite if exposed to a source of ignition. For many paraffin waxes, this can be as low as 390°F (200°C).

A double boiler makes it physically difficult to overheat the wax to its flash point, as the wax temperature will not significantly exceed the boiling point of water (212°F / 100°C). This is your single most important built-in safety feature.

Critical Safety Procedures During Melting

With the principles understood, the specific actions you must take become clear and logical. These are not just rules; they are practical applications of heat management.

Constant Supervision is Non-Negotiable

Never, under any circumstance, walk away from melting wax. An unattended pot is a significant fire risk. A water boil-off, a tipped pot, or a sudden temperature spike can happen quickly.

Maintain the Water Gap

The bottom of the upper pot (or pouring pot) must not touch the water in the lower pot. There should be a gap of at least one to two inches.

If the pot touches the water, the heat is no longer indirect. It becomes direct conduction, defeating the purpose and safety of the double boiler and creating a risk of scorching the wax.

Manage Your Water Level

The system relies on a steady supply of steam. Keep an eye on the water level in the bottom pot, especially during long melting sessions.

If the water boils away completely, the bottom of the pot can overheat rapidly, creating a severe fire hazard and likely ruining your pot. Keep a kettle of hot water nearby to top it off as needed.

Use Appropriate Protective Equipment

Molten wax is extremely hot and can cause serious burns. Always wear heat-resistant gloves when handling the pouring pot. Safety goggles are also highly recommended to protect your eyes from accidental splashes.

Common Pitfalls to Avoid

Even with a safe setup, common mistakes can compromise your safety and the quality of your candles.

The Risk of Water Contamination

Be careful to prevent steam or water droplets from getting into your melting wax. Water contamination will cause "frosting" or bubbles in the finished candle and can make the candle sputter or crackle when burned.

Ensure your upper pot rests securely and doesn't allow excessive steam to curl up and into it.

The Mistake of a Raging Boil

You do not need a vigorous, rolling boil in the bottom pot. A gentle simmer is all that is required to produce enough steam to melt the wax effectively.

A hard boil increases the risk of water splashing into your wax and makes the water level drop much faster. It offers no benefit.

Improper Cleaning and Wax Buildup

Clean your pouring pot while it is still warm (but not hot). A simple wipe with a paper towel is often enough to remove the vast majority of residual wax.

Allowing wax to build up over time can cause cross-contamination of scents and colors between batches. More importantly, a thick layer of old wax can itself become a fire hazard if it is ever overheated.

Making the Right Choice for Your Goal

Your approach should be guided by your priorities for each candle-making session.

- If your primary focus is safety: Never leave your melting wax unattended and always ensure the water level in the bottom pot is sufficient.

- If your primary focus is candle quality: Maintain a gap between the simmering water and the pouring pot to ensure gentle, even heating and prevent scorching.

- If your primary focus is efficiency: Dedicate a specific pouring pot and tools to candle making and clean them thoroughly with a paper towel while the equipment is still warm.

By mastering these fundamental precautions, you ensure every candle-making session is both safe and successful.

Summary Table:

| Precaution | Key Action | Why It Matters |

|---|---|---|

| Constant Supervision | Never leave melting wax unattended. | Prevents fire hazards from wax reaching its flash point. |

| Maintain Water Gap | Ensure upper pot does not touch the water. | Prevents scorching and ensures gentle, indirect heating. |

| Use Protective Gear | Wear heat-resistant gloves and safety goggles. | Protects against serious burns from hot wax splashes. |

| Manage Water Level | Keep bottom pot filled; top off with hot water. | Prevents the pot from overheating if water boils away. |

| Proper Cleaning | Wipe equipment clean while still warm. | Prevents wax buildup, cross-contamination, and fire risks. |

Ready to scale up your candle-making operation with professional-grade equipment?

As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-capacity tools you need for safe and efficient production. Our products are designed to meet the demands of professionals who prioritize both safety and quality.

Contact our expert team today to discuss how our wholesale-focused solutions can enhance your workflow and help your business grow.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Classic Glass Honey Jar with Metal Lug Cap for Beehive Storage

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

People Also Ask

- What is the primary function of a honey screw press? Maximize Yield with Advanced Cold Press Separation Technology

- How does a honey screw press operate to separate honey from wax? Boost Your Apiary Efficiency

- What happens to the wax after extraction by the Wax Screw Press? Efficient Post-Extraction Processing Guide

- How can the use of specialized beekeeping hardware like propolis grids and wax presses improve production? Scale Now

- What are the benefits of a Honey-Wax Separating Screw Press? Boost Honey Yield & Efficiency