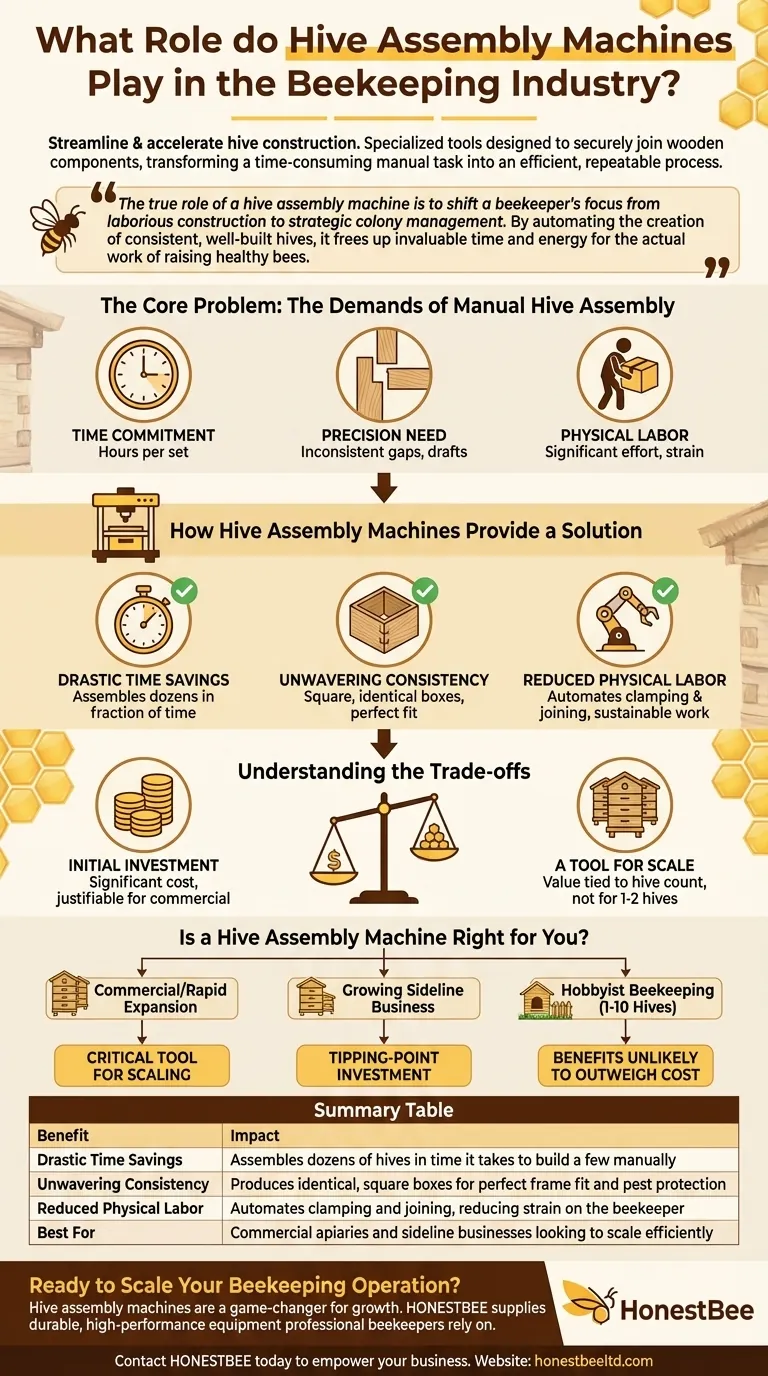

In short, hive assembly machines streamline and accelerate the construction of beehives. They are specialized tools designed to securely join the wooden components of a hive box, transforming a time-consuming manual task into an efficient, repeatable process. This technology makes beekeeping more productive and accessible for both commercial and serious hobbyist operations.

The true role of a hive assembly machine is to shift a beekeeper's focus from laborious construction to strategic colony management. By automating the creation of consistent, well-built hives, it frees up invaluable time and energy for the actual work of raising healthy bees.

The Core Problem: The Demands of Manual Hive Assembly

Before understanding the machine, it's essential to understand the problem it solves. Building beehives by hand has been the standard for centuries, but it comes with inherent challenges.

The Time Commitment

Even for an experienced woodworker, manually assembling hive bodies is a meticulous process. It requires careful alignment, clamping, and fastening, often taking hours to produce a single set of boxes.

The Need for Precision

A beehive is more than just a box; it's a precisely engineered environment. Inconsistent gaps or misaligned joints can create drafts, allow pests to enter, and make hive inspections more difficult for the beekeeper.

How Hive Assembly Machines Provide a Solution

These machines address the core challenges of manual assembly by introducing efficiency and uniformity into the process. They function as a jig and press, ensuring every hive component is joined perfectly.

Drastic Time Savings

The most significant benefit is speed. A task that takes hours by hand can be reduced to a fraction of the time, allowing beekeepers to assemble dozens of hives in the time it would take to build a few manually.

Unwavering Consistency

Machines eliminate human error. Every box produced is square and identical, ensuring frames fit perfectly and hive bodies stack securely. This consistency can contribute to improved colony health by creating a more stable and protected environment.

Reduced Physical Labor

Assembling many hives requires significant physical effort. A machine automates the clamping and joining process, reducing the strain on the beekeeper and making the work more sustainable.

Understanding the Trade-offs

While beneficial, these machines are not a universal solution for every beekeeper. Objectivity requires acknowledging their specific place in the industry.

Initial Investment

Hive assembly machines represent a significant financial investment. Their cost is often justifiable for commercial operations or large-scale sideliners but can be prohibitive for a hobbyist with only a few hives.

A Tool for Scale

The value of this equipment is directly tied to the number of hives being managed. A beekeeper with one or two backyard hives will not experience the same return on investment as an apiarist managing hundreds of colonies.

Is a Hive Assembly Machine Right for You?

The decision to invest in this technology depends entirely on your operational goals and scale.

- If your primary focus is commercial production or rapid expansion: A hive assembly machine is a critical tool for scaling your operation efficiently and maintaining high standards of quality.

- If your primary focus is a growing sideline business: This machine can be a tipping-point investment, freeing up time to manage more colonies and increase profitability.

- If your primary focus is hobbyist beekeeping (1-10 hives): The benefits are unlikely to outweigh the cost, and traditional manual assembly remains the most practical and economical approach.

Ultimately, this technology empowers beekeepers to scale their passion or business by handling the woodwork, so they can focus on the bees.

Summary Table:

| Benefit | Impact |

|---|---|

| Drastic Time Savings | Assembles dozens of hives in the time it takes to build a few manually. |

| Unwavering Consistency | Produces identical, square boxes for perfect frame fit and pest protection. |

| Reduced Physical Labor | Automates clamping and joining, reducing strain on the beekeeper. |

| Best For | Commercial apiaries and sideline businesses looking to scale efficiently. |

Ready to Scale Your Beekeeping Operation?

Hive assembly machines are a game-changer for commercial apiaries and beekeeping equipment distributors focused on growth. By automating hive construction, you can redirect valuable time and labor toward strategic colony management and business expansion.

HONESTBEE supplies the durable, high-performance equipment that professional beekeepers rely on. Let us help you integrate this efficient technology into your workflow.

Contact HONESTBEE today to discuss how our wholesale-focused solutions can empower your business to build more hives and raise healthier bees.

Visual Guide

Related Products

- HONESTBEE Top Bar & Bottom Bar Forming Machine | Bee Frame Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Automatic Finger Joints Joint Making Machine for Bee Box and Hive Making

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- Why is automated beehive manufacturing and repair machinery essential? Scale Your Apiary with Industrial Precision

- What are the advantages of industrial beehive making machines? Scale Your Beekeeping with Precision and Standardization

- What are the benefits of implementing specialized hive-making machinery? Transform Your Beekeeping Supply Chain Efficiency

- What are the benefits of industrial-grade hive-making machinery? Scale Your Apiary with High-Precision Automation

- What data does a universal material testing machine provide for beehive composites? Ensure Long-Term Hive Durability

- What are the core benefits of industrial beehive making machinery? Scale Your Apiary with Precision & Efficiency

- How does the use of precision hive-making machinery benefit large-scale commercial beekeeping? Scale Your Apiary Faster

- What are the main disadvantages of using horizontal hives? Challenges in Logistics, Extraction, and Scalability