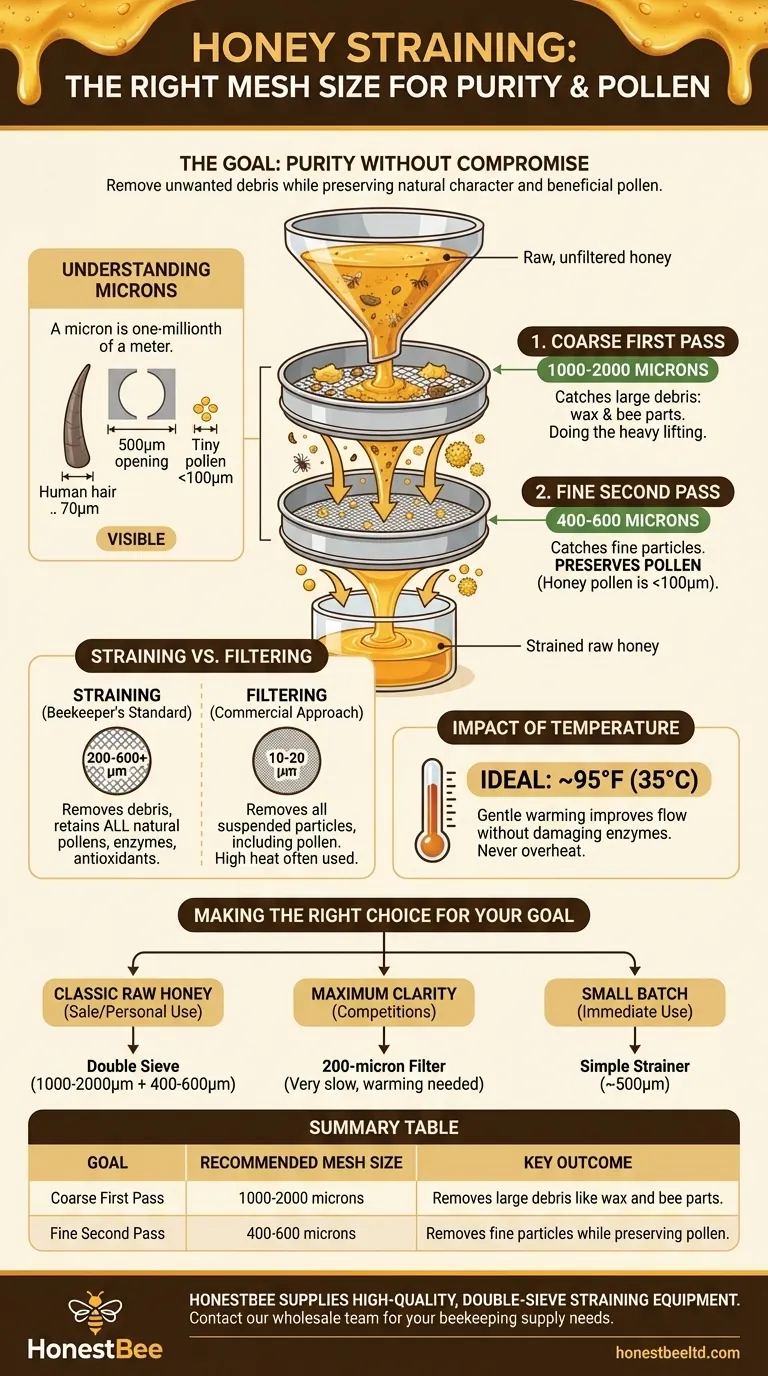

For straining raw honey, the standard practice is to use a double-sieve system. This involves a coarse top mesh of approximately 1000-2000 microns to catch large debris like wax and bee parts, followed by a finer bottom mesh of 400-600 microns. This two-stage process effectively cleans the honey of visible impurities without removing the beneficial pollen, which is much smaller.

The goal of straining is not to sterilize the honey but to remove unwanted debris while preserving its natural character. The mesh size you choose is a critical decision that balances clarity with the preservation of beneficial components like pollen.

The Goal of Straining: Purity Without Compromise

When you harvest honey, it inevitably contains small bits of beeswax, wood from the frames, and sometimes bee parts. Straining is the essential step to remove these particles before bottling.

Removing Debris

The primary purpose of straining is to create a clear, appealing product. Particles of wax and other hive debris are harmless but can be unappealing to the consumer and can accelerate crystallization.

Preserving Pollen

Crucially, standard straining is designed to preserve pollen. Honey pollen grains are microscopic, with even the largest being less than 100 microns in size. A 400- or 600-micron sieve is more than four times larger, allowing all the natural pollen to pass through easily.

Understanding Microns

A micron is a unit of measure equal to one-millionth of a meter. For perspective, a typical human hair is about 70 microns thick. A 500-micron opening is therefore quite visible, designed to stop noticeable particles but not microscopic ones.

The Standard Double-Sieve Method

For efficiency and effectiveness, nearly all beekeepers use a two-stage straining method. This prevents the finer filter from clogging immediately and speeds up the entire process.

The Coarse First Pass (1000-2000 Microns)

The top, or coarse, sieve is your first line of defense. It has large openings, typically between 1000 and 2000 microns (1-2 mm).

This layer catches all the large "gunk" from the uncapping and extraction process, doing the heavy lifting so the finer sieve doesn't have to.

The Fine Second Pass (400-600 Microns)

The bottom, or fine, sieve completes the job. With a mesh size between 400 and 600 microns, it catches smaller specks of wax and other fine particles that passed through the coarse filter.

This is the industry standard for clean, raw honey that still contains all its natural pollen. Honey passed through a 400-micron sieve is considered perfectly strained and ready for bottling.

Understanding the Trade-offs: Straining vs. Filtering

The terms "straining" and "filtering" are often used interchangeably, but they represent two very different processes with different outcomes.

Straining: The Beekeeper's Standard

Straining uses a mesh of 200 microns or larger. As we've discussed, the 400-600 micron range is ideal. It removes visible debris while retaining all the natural pollens, enzymes, and antioxidants that define raw honey.

Filtering: The Commercial Approach

Filtering is a more aggressive process common in large-scale commercial packing. It often involves heating honey to make it less viscous and then pressure-forcing it through a very fine filter, sometimes as small as 10-20 microns.

This process removes all suspended particles, including pollen. While it produces a brilliantly clear product with a long shelf life, it also strips the honey of the very components that give it its unique character and nutritional value.

The Impact of Honey Temperature

The viscosity of honey is highly dependent on temperature. Cold honey is extremely thick and will barely pass through a fine sieve.

Gently warming your honey to around 95°F (35°C) will make it flow much more easily, significantly speeding up the straining process without damaging the honey's beneficial enzymes. Never overheat it.

Making the Right Choice for Your Goal

Your choice of mesh depends entirely on what you want to achieve with your final product.

- If your primary focus is producing classic, raw honey for sale or personal use: Use a standard double sieve with a coarse (1000-2000 micron) and fine (400-600 micron) mesh.

- If your primary focus is maximum clarity for honey competitions: You might use a 200-micron filter as your final step, but know that this will be extremely slow without warming the honey.

- If you are simply cleaning a small batch for immediate use: A simple nylon straining bag or a fine-mesh kitchen sieve (often around 500 microns) will remove the largest particles effectively.

By selecting the right mesh, you ensure your honey is clean and visually appealing while preserving the natural qualities that make it a unique and valuable product.

Summary Table:

| Goal | Recommended Mesh Size | Key Outcome |

|---|---|---|

| Coarse First Pass | 1000-2000 microns | Removes large debris like wax and bee parts. |

| Fine Second Pass | 400-600 microns | Removes fine particles while preserving pollen. |

Ready to strain your honey like a pro?

HONESTBEE supplies the high-quality, double-sieve straining equipment that commercial apiaries and distributors trust. Our products are designed for efficiency and to help you maintain the raw, natural quality of your honey.

Contact our wholesale team today to discuss your beekeeping supply needs and get the right equipment for your operation.

Visual Guide

Related Products

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- Why use fine-pored filtration for bee feed? Ensure Colony Health and Equipment Reliability

- How do I choose a mesh size for a strainer? Balance Protection and Performance

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What micron to strain honey? A Beekeeper's Guide to Clarity and Quality

- Why is a Synthetic Cloth Mesh used in honey filtration? Ensure Purity and Chemical Integrity in Your Honey Samples