The right staple for wood depends entirely on your specific task. For delicate work like attaching trim or lattice, an 18-gauge narrow crown staple is ideal because its thin wire fastens the wood securely without causing it to split. For heavier tasks like sheathing or framing, a thicker, lower-gauge staple is required for its superior holding power.

The core principle of choosing a wood staple is balancing holding power against the risk of damaging the material. The thinner the staple (higher gauge), the less likely it is to split the wood, making it perfect for fine work. The thicker the staple (lower gauge), the stronger its hold, making it necessary for structural applications.

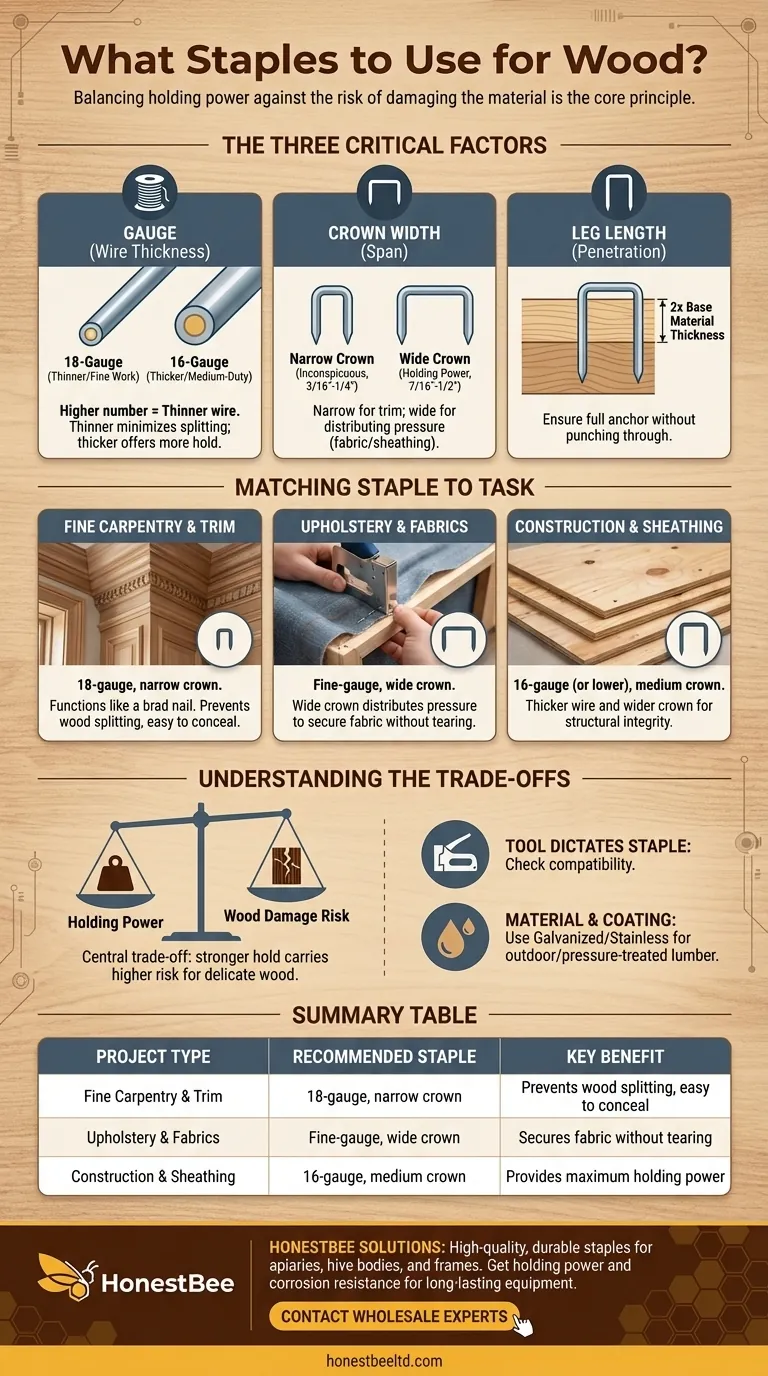

The Three Critical Factors in Choosing a Wood Staple

To select the correct staple, you must understand three key measurements: gauge, crown, and length. Each one plays a distinct role in the staple's performance.

Staple Gauge: The Thickness of the Wire

The gauge refers to the thickness of the staple's wire. Confusingly, a higher gauge number means a thinner wire.

An 18-gauge staple has a very thin wire, making it perfect for fine carpentry, trim, and delicate wood projects. As noted for lattice, its primary benefit is minimizing the risk of splitting the wood.

A 16-gauge staple is a medium-duty fastener, offering a good balance of holding power and a relatively small entry hole. It's often used for subflooring, sheathing, and fencing.

Crown Width: The Span of the Staple

The crown is the horizontal top of the staple. The width of the crown dictates how much surface area the staple covers.

A narrow crown (e.g., 3/16" or 1/4") is designed to be inconspicuous. It drives deeper and is easier to hide with wood filler, making it the standard for trim and cabinetry.

A medium or wide crown (e.g., 7/16" or 1/2") is used when holding power is more important than appearance. This wider span is excellent for securing sheathing, house wrap, or upholstery fabric without tearing through the material.

Leg Length: Ensuring Proper Penetration

The staple's leg length determines how deep it penetrates the wood. The goal is to fully anchor the top piece of material into the base piece without punching all the way through.

A common rule is that the staple should penetrate the base material by at least twice the thickness of the material being fastened. For example, when attaching 1/4" plywood, you want at least 1/2" of the staple to go into the underlying wood.

Matching the Staple to Your Woodworking Task

Different applications demand fundamentally different types of staples. Using the wrong one can lead to a weak bond or damaged work.

For Fine Carpentry and Trim

This is where high-gauge, narrow crown staples excel. An 18-gauge staple with a narrow crown is the professional's choice for attaching trim, molding, or lattice.

It functions like a tiny, double-pronged brad nail, providing a secure hold while leaving a minimal hole that is easily concealed.

For Upholstery and Fabrics

When attaching fabric to a wood frame, the priority is to hold the material without ripping it. This calls for a wide crown, fine-gauge staple (like the common T50 type).

The wide crown distributes pressure across the fabric's surface, preventing the thin wire from tearing through under tension.

For General Construction and Sheathing

Tasks like fastening plywood sheathing, subflooring, or assembling crates require significant holding power. Here, a 16-gauge (or lower) medium crown staple is the appropriate tool.

The thicker wire and wider crown provide the structural integrity needed to hold heavy materials together securely.

Understanding the Trade-offs

Choosing a staple is never about finding the "strongest" one; it's about finding the right one for the job, which always involves compromises.

Holding Power vs. Wood Damage

This is the central trade-off. A heavy-duty, low-gauge staple offers immense holding power but carries a high risk of splitting thinner or more delicate wood. An 18-gauge staple is gentle on the wood but won't hold a subfloor in place.

The Tool Dictates the Staple

You cannot use any staple in any staple gun. Every tool is specifically designed for a certain range of gauges and crown widths. Always check your tool's specifications before purchasing staples to ensure they are compatible.

Material and Coating

For outdoor projects or use in pressure-treated lumber, you must use staples with a protective coating. Galvanized or stainless steel staples resist corrosion and rust, preventing stains and ensuring the fastener's longevity.

Making the Right Choice for Your Project

Evaluate your goal and select the fastener designed to achieve it.

- If your primary focus is delicate trim or lattice: Use a high-gauge (18-gauge or higher) narrow crown staple to prevent splitting the wood.

- If your primary focus is attaching fabric or upholstery: Choose a wide crown staple to secure the material without tearing it.

- If your primary focus is construction or sheathing: Select a medium crown, lower-gauge (e.g., 16-gauge) staple for maximum holding power.

By matching the staple's gauge, crown, and length to your specific material and task, you ensure a secure and flawless result.

Summary Table:

| Project Type | Recommended Staple | Key Benefit |

|---|---|---|

| Fine Carpentry & Trim | 18-gauge, narrow crown | Prevents wood splitting, easy to conceal |

| Upholstery & Fabrics | Fine-gauge, wide crown | Secures fabric without tearing |

| Construction & Sheathing | 16-gauge, medium crown | Provides maximum holding power for heavy materials |

Achieve professional results on every project with the right staples. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable staples perfect for building hive bodies, frames, and other wooden components. Get the holding power and corrosion resistance you need for long-lasting equipment. Contact our wholesale experts today to discuss your specific requirements and bulk pricing.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Queen Grafting Tool for Beekeeping and Bee Queen Grafting

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

People Also Ask

- How do adjustable plugs and foam inserts function within cylindrical beekeeping hives? Optimize Hive Volume

- What is the functional role of a Bee Hive in honey production? Boost Efficiency with Optimized Infrastructure

- How do high-precision temperature sensors assist in beehive health? Master Real-Time Colony Monitoring

- What are the benefits of using hive assembly machines in beekeeping? Scale Your Apiary with Industrial Precision

- What is the purpose of hive assembly machines in beekeeping? Boost Efficiency for Your Apiary

- How does high-performance woodworking machinery support the beekeeping industry? Boost Production & Standardization

- What is the technical value of specialized hive-making machinery? Scale Your Apiary with Industrial Precision

- Why do commercial beekeeping operations require automated hive-making and frame-processing machinery? Scaling for Success