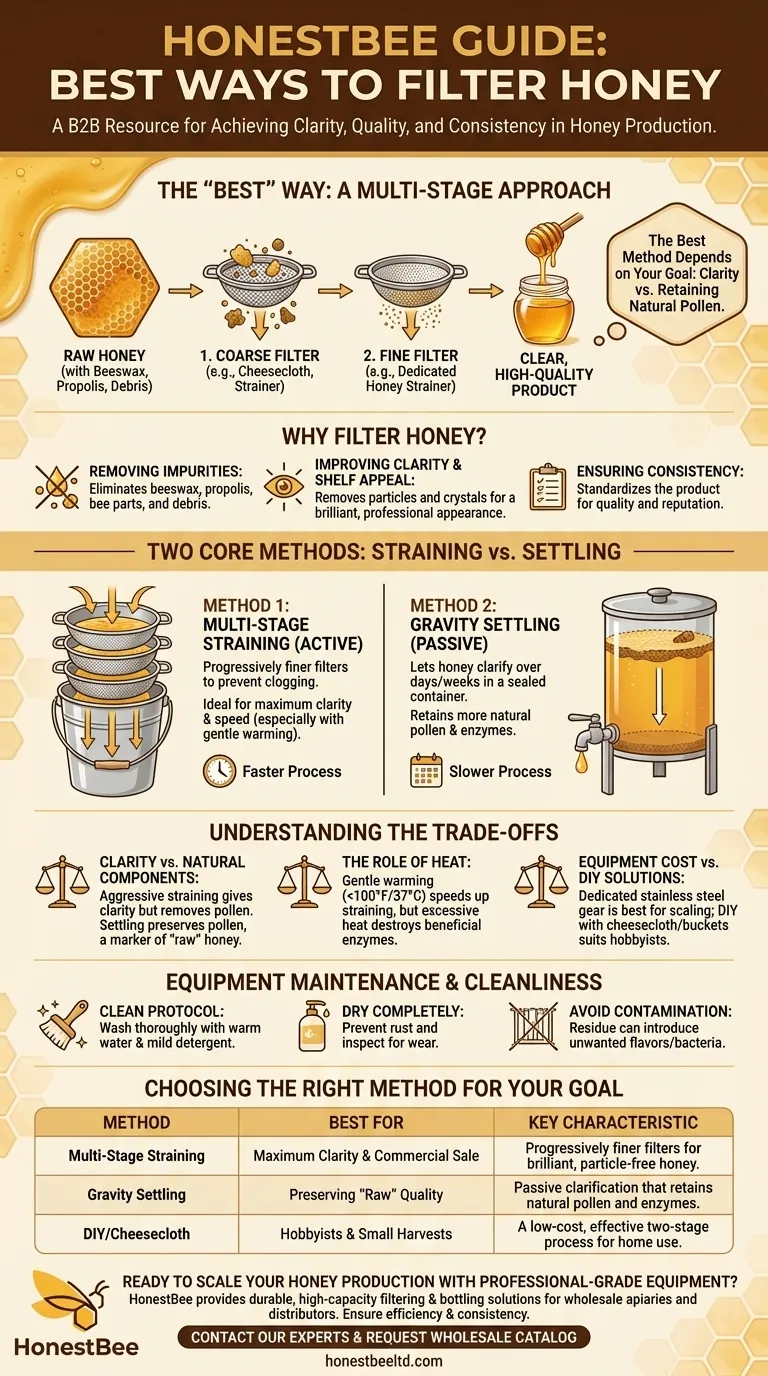

The most effective way to filter honey is through a multi-stage process that removes impurities sequentially. You should always start with a coarse filter, like cheesecloth held over a strainer, to catch large debris such as beeswax and wood splinters. Afterward, pass the honey through a finer filter, such as a dedicated honey strainer or even clean pantyhose, to achieve a clear, high-quality final product.

The "best" filtering method is not one-size-fits-all; it depends entirely on your end goal. The central trade-off is between achieving crystal-clear honey for commercial appeal and preserving the maximum amount of natural pollen and enzymes for "raw" honey.

Why Filter Honey?

Filtering is a critical step in honey processing that moves it from a raw harvest to a finished product. The primary goals are purification and presentation.

Removing Physical Impurities

Raw honey straight from the hive contains various particles you don't want in the final jar. Filtering effectively removes bits of beeswax, propolis, bee parts, and other debris that fall in during extraction.

Improving Clarity and Shelf Appeal

For beekeepers who sell their honey, appearance is crucial. Filtering removes tiny particles and sugar crystals that can make honey appear cloudy. A clear, brilliant honey has significantly more appeal to customers.

Ensuring a Consistent Product

A standardized filtering process ensures that every jar of honey you produce meets the same quality standard. This consistency is key to building a reputation for a high-quality product.

The Two Core Methods: Straining vs. Settling

While there are many variations, processing honey generally comes down to two main philosophies: actively straining it or passively letting it clarify on its own.

Method 1: Multi-Stage Straining (The Active Approach)

This is the most common method. The core principle is to use progressively finer filters. Forcing honey through a very fine filter from the start will cause it to clog instantly.

A typical hobbyist setup involves layering cheesecloth inside a larger kitchen strainer. For a more professional result, dedicated stainless steel honey strainers are available, often in sets that nest inside a 5-gallon bucket.

Method 2: Gravity Settling (The Passive Approach)

If your goal is to preserve the honey in its most natural state, you can filter it without any strainers at all. This involves letting the honey sit in a sealed bottling container for several days or weeks.

Over time, the lighter wax and debris will float to the top, while heavier particles sink. You can then use a spigot at the bottom of the container to bottle the clear honey from the middle, leaving the impurities behind.

Understanding the Trade-offs

Choosing a filtering method involves balancing clarity, preservation of natural compounds, and effort.

Clarity vs. Natural Components

Aggressive straining with very fine filters produces exceptionally clear honey but can remove some of the naturally occurring pollen. While not a nutrient powerhouse, pollen is a key marker of "raw" and unfiltered honey, which many consumers seek. Settling, by contrast, preserves the most pollen.

The Role of Heat

Honey is viscous and filters slowly. Gently warming the honey (not to exceed 100°F or 37°C) will lower its viscosity and speed up the straining process significantly. However, excessive heat will destroy the beneficial enzymes that define raw honey and can alter its flavor. Never use a microwave or direct, high heat.

Equipment Cost vs. DIY Solutions

Dedicated equipment, such as stainless steel filters, pumps, and bottling tanks, streamlines the process and is essential for larger operations. However, for a small-scale beekeeper, simple and inexpensive DIY solutions using cheesecloth and food-grade buckets are perfectly adequate.

How to Maintain Your Equipment

Proper maintenance prevents contamination and extends the life of your tools. Contaminated equipment can ruin an entire batch of honey.

The Importance of Cleanliness

Residue from old honey or wax can introduce unwanted flavors and bacteria into your new harvest. Every component that touches the honey must be thoroughly cleaned before and after use.

A Simple Cleaning Protocol

Wash all filters, buckets, and tools with warm water and a mild, unscented detergent. Rinse thoroughly to remove any soap residue.

Dry Thoroughly and Inspect

After washing, all parts must be dried completely to prevent rust or corrosion on metal components. Before your next use, inspect filters for any wear and tear and check fittings on bottling tanks for leaks.

Choosing the Right Method for Your Goal

Your ideal filtering strategy should be directly aligned with the type of product you want to create.

- If your primary focus is maximum clarity for sale: Use a multi-stage stainless steel strainer system, and consider gently warming the honey to speed the process.

- If your primary focus is preserving the "raw" character of the honey: Use the passive gravity settling method in a bottling tank to clarify the honey without aggressive filtering.

- If you are a hobbyist with a small harvest: A simple and low-cost two-stage system using cheesecloth followed by a finer strainer is a highly effective starting point.

By matching your technique to your goal, you can consistently produce a high-quality honey that you can be proud of.

Summary Table:

| Method | Best For | Key Characteristic |

|---|---|---|

| Multi-Stage Straining | Maximum Clarity & Commercial Sale | Progressively finer filters for brilliant, particle-free honey. |

| Gravity Settling | Preserving "Raw" Quality | Passive clarification that retains natural pollen and enzymes. |

| DIY/Cheesecloth | Hobbyists & Small Harvests | A low-cost, effective two-stage process for home use. |

Ready to scale your honey production with professional-grade equipment?

As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-capacity filtering and bottling equipment you need to ensure efficiency and product consistency. Let us help you choose the right system for your operation's goals.

Contact our experts today to discuss your specific needs and request a wholesale catalog.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Premium Diamond-Faceted Glass Honey Dispenser

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

People Also Ask

- What methods are used for straining honey? Choose the Right Method for Your Scale

- How does a double sieve honey strainer work? Achieve Crystal Clear Honey with Professional Two-Stage Filtration

- How does honey filtering and storage equipment affect market value? Maximize Profits with Single-Origin Quality

- What is the function of honey sieves, strainers, and filters in processing? Master the 3 Stages of Honey Purity

- Should honey be filtered or unfiltered? Maximize Health Benefits with Raw Honey