In large-scale beekeeping, hive assembly is a critical operational bottleneck. Hive assembly machines directly address this challenge by automating and expediting the construction process. They drastically reduce the manual labor hours required to build or repair hives, which allows commercial operations to manage and expand their apiaries far more efficiently than with manual methods alone.

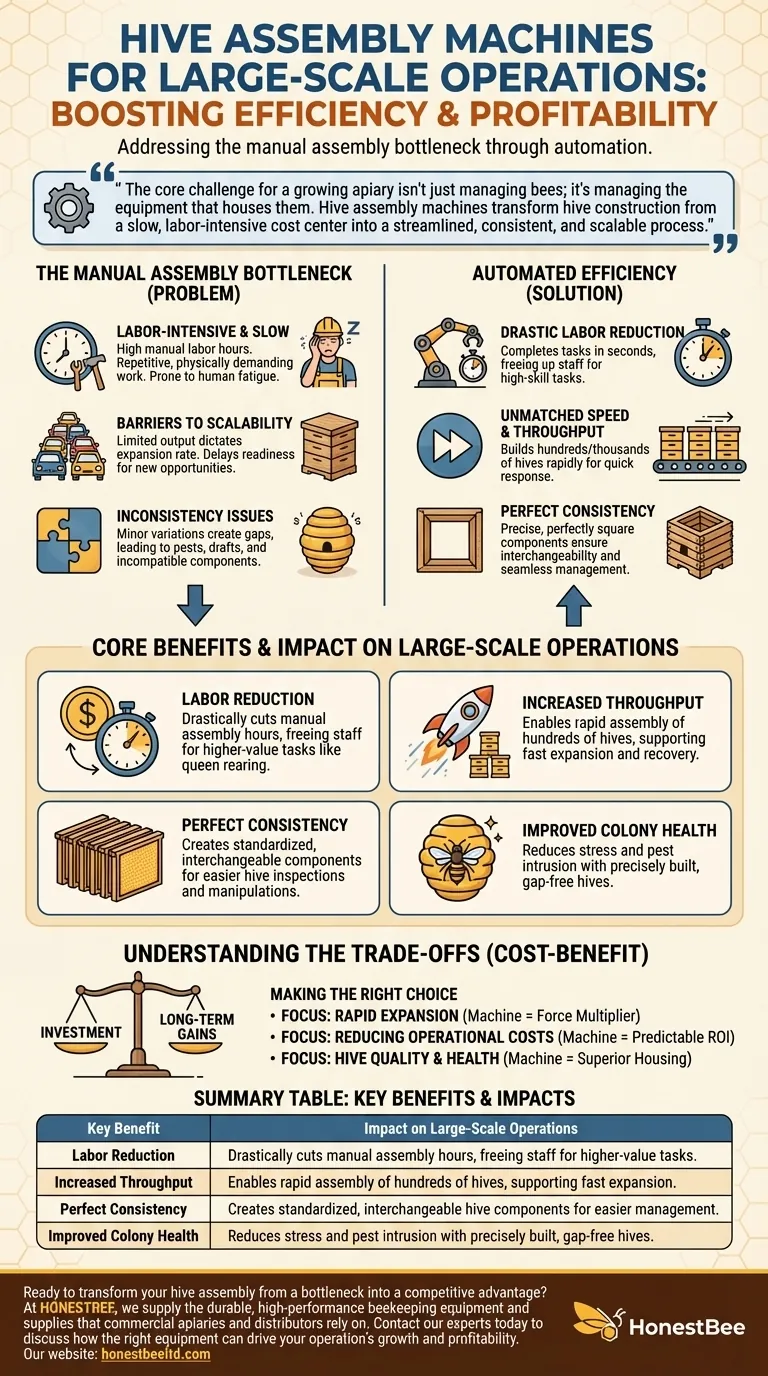

The core challenge for a growing apiary isn't just managing bees; it's managing the equipment that houses them. Hive assembly machines transform hive construction from a slow, labor-intensive cost center into a streamlined, consistent, and scalable process.

The Core Challenge: The Manual Assembly Bottleneck

For any commercial beekeeping operation, time and labor are finite resources. Manual hive assembly consumes vast quantities of both, creating a significant barrier to growth and profitability.

The Hidden Costs of Labor

Manually building hive bodies, supers, and frames is repetitive and physically demanding work. The primary cost is not just wages, but also the associated expenses of training, managing a larger workforce, and the inevitable slowdowns caused by human fatigue.

Barriers to Scalability

The rate of manual assembly directly dictates the speed at which an operation can expand. If you need to deploy 500 new hives for pollination contracts or to replace winter losses, a manual approach can take weeks and require a dedicated team, delaying your readiness and impacting revenue.

The Problem of Inconsistency

Even with skilled workers, manually assembled hives will have minor variations. A slightly misaligned joint or an improperly nailed frame can create gaps. These imperfections can lead to issues with brace comb, drafts, and pest intrusion, affecting colony health and making hive components less interchangeable.

How Hive Assembly Machines Drive Efficiency

Automated systems are not just about speed; they introduce a level of precision and reliability that has a cascading positive effect on the entire operation.

Drastic Reduction in Labor Hours

This is the most immediate and quantifiable benefit. A task that might take a worker several minutes per box is completed by a machine in seconds. This frees up valuable labor to be reallocated to more critical, high-skill apiary tasks like queen rearing or disease management.

Unmatched Speed and Throughput

Hive assembly machines are designed for high-volume output. They enable an operation to build hundreds or even thousands of hive bodies and frames in a fraction of the time. This expedites hive construction and provides the agility to respond quickly to new opportunities or recover from equipment losses.

Achieving Perfect Consistency

Machines operate with tight tolerances, producing perfectly square and securely joined hive components every time. This consistency is critical for large-scale management. Standardized equipment ensures all parts are interchangeable, simplifying hive inspections and manipulations across thousands of colonies.

Enhancing Long-Term Colony Health

A perfectly constructed hive is a healthier home for bees. The absence of small gaps and cracks means the colony spends less energy on sealing drafts with propolis and is better protected from pests like wax moths or small hive beetles. This leads to reduced colony stress and supports more robust, productive hives.

Understanding the Trade-offs

While the benefits are clear, adopting this technology is a significant decision that requires a cost-benefit analysis. Objectivity is crucial.

The Upfront Capital Investment

These machines represent a major capital expenditure. The return on investment must be calculated based on your operation's scale, labor costs, and growth plans. It is not a solution for every small-scale beekeeper.

Maintenance and Space Requirements

Like any piece of industrial equipment, an assembly machine requires a dedicated footprint in a workshop, access to power, and a regular maintenance schedule. These operational factors must be planned for.

The Break-Even Point

An operation must have a sufficient and consistent need for new or replacement equipment to justify the investment. If you only assemble a few dozen hives a year, the costs will almost certainly outweigh the labor savings.

Making the Right Choice for Your Operation

The decision to invest in a hive assembly machine should be tied directly to your strategic goals.

- If your primary focus is rapid expansion: A machine is a force multiplier, enabling you to build out the necessary equipment far faster than is possible with manual labor alone.

- If your primary focus is reducing operational costs: The machine provides a clear and predictable return on investment by significantly lowering the recurring labor expense associated with hive assembly.

- If your primary focus is hive quality and colony health: The precision of automated assembly creates superior, standardized housing that reduces colony stress and supports higher productivity.

Ultimately, adopting hive assembly automation is a strategic move to transform a necessary chore into a tangible competitive advantage.

Summary Table:

| Key Benefit | Impact on Large-Scale Operations |

|---|---|

| Labor Reduction | Drastically cuts manual assembly hours, freeing staff for higher-value tasks. |

| Increased Throughput | Enables rapid assembly of hundreds of hives, supporting fast expansion. |

| Perfect Consistency | Creates standardized, interchangeable hive components for easier management. |

| Improved Colony Health | Reduces stress and pest intrusion with precisely built, gap-free hives. |

Ready to transform your hive assembly from a bottleneck into a competitive advantage?

At HONESTBEE, we supply the durable, high-performance beekeeping equipment and supplies that commercial apiaries and distributors rely on. Our wholesale-focused operations are designed to support your scale and efficiency goals.

Contact our experts today to discuss how the right equipment can drive your operation's growth and profitability.

Visual Guide

Related Products

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

People Also Ask

- How does specialized woodworking machinery support beekeeping expansion? Scale Your Apiary with Industrial Precision

- How does a beehive function as core equipment for maintaining the microenvironment? Master Colony Climate Control

- What are the advantages of standardized industrialized beehives? Boost Your Commercial Apiary Yield and Efficiency

- How do hive-making machines contribute to the industrialization of beekeeping? Scale Your Apiary Operations

- What is the primary role of automated beehive manufacturing equipment? Boost Precision and Commercial Scalability

- How do automated hive-making machines develop forest beekeeping? Unlock Scalable Commercial Honey Production

- Why are wide-angle cameras and mirrors used in smart beehives? Optimize Image Recognition & Mite Detection

- What is the significance of industrial woodworking machinery for beehive manufacturing in modern beekeeping?