The fundamental reason metal eyelets are used in frame wiring is to protect the wood. They create a durable, smooth barrier that prevents the high-tension wire from cutting into and damaging the wooden frame over time.

The core problem is that beekeeping frame wire must be extremely tight to support the wax foundation. This tension is high enough to slice into the soft wood of the frame, causing the wire to loosen and the frame to fail prematurely. Eyelets act as a simple, effective reinforcement.

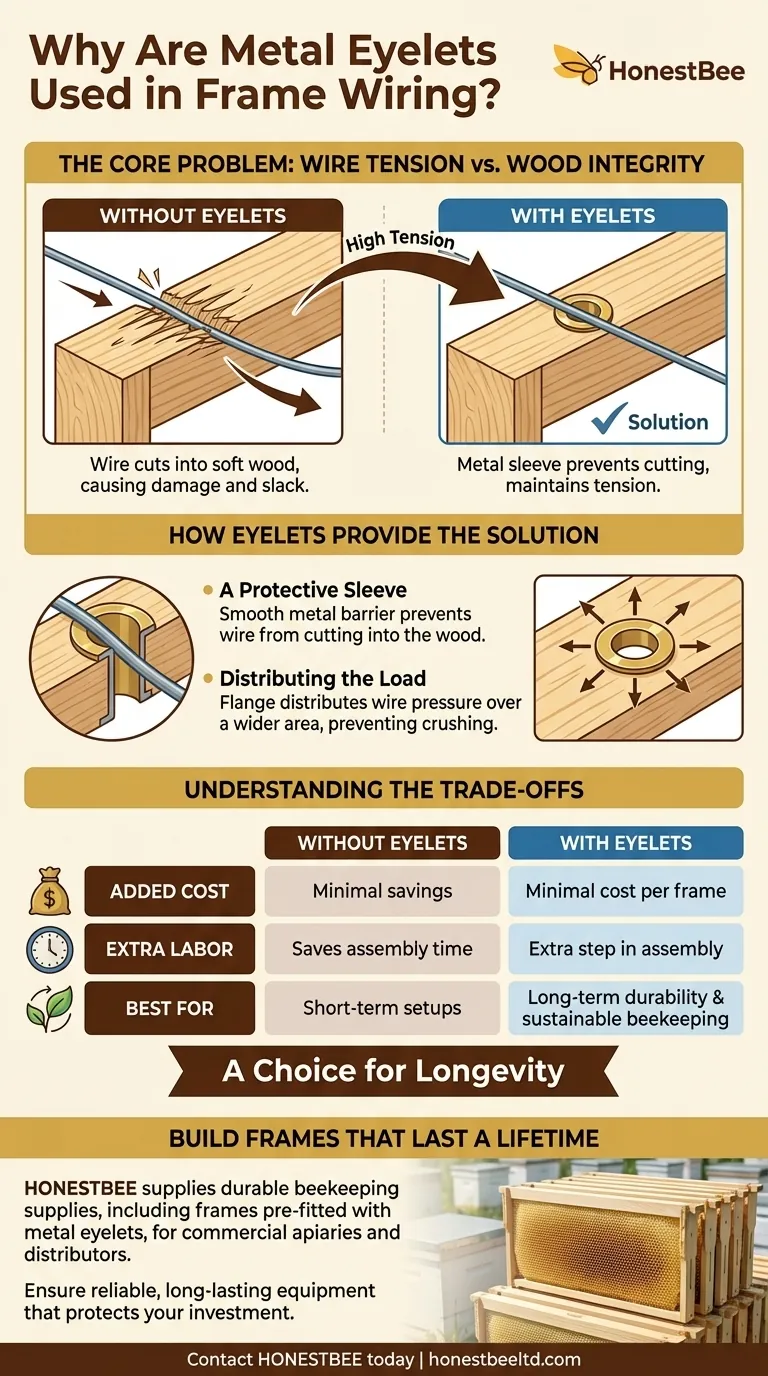

The Problem: Wire Tension vs. Wood Integrity

To understand the role of eyelets, we must first appreciate the forces at play within a wired beehive frame. The entire system is a balance between the need for rigid support and the limitations of the materials used.

The Purpose of Frame Wire

The primary job of the wire is to support and stabilize the sheet of wax or plastic foundation placed within the frame. This foundation is what the bees build their honeycomb on.

Without proper support, the foundation can sag, bulge, or warp, especially under the weight of honey and the heat of the hive. This leads to misshapen comb that can be difficult for beekeepers to inspect and manage.

The Necessity of High Tension

To prevent sagging, the wire must be pulled incredibly tight—often to the point where it hums like a guitar string when plucked.

This high tension is critical for creating a rigid support structure that holds the foundation perfectly flat, encouraging the bees to build straight, even comb.

The Vulnerability of Wood

Most beehive frames are made from softwoods like pine. While cost-effective and lightweight, this wood is susceptible to damage.

When a thin, high-tension wire is pulled against the edge of a drilled hole in soft pine, it acts like a miniature saw. Over time, the wire will cut deeper into the wood, causing the tension to slacken and compromising the frame's integrity.

How Eyelets Provide the Solution

Metal eyelets are a simple and elegant piece of engineering that completely neutralizes the core problem of wire cutting into wood.

A Protective Sleeve

An eyelet is essentially a small metal grommet or sleeve that is inserted into the pre-drilled holes in the frame's side bars.

The wire is then threaded through these eyelets instead of making direct contact with the wood. The smooth, hard metal surface prevents any cutting action, no matter how tight the wire is pulled.

Distributing the Load

The flange, or rim, of the eyelet also plays a crucial role. It sits flush against the frame and distributes the wire's pressure over a much wider surface area.

This prevents the wood fibers immediately around the hole from crushing or splintering under the concentrated force of the wire.

Understanding the Trade-offs

While highly effective, using eyelets is a choice with practical implications for the beekeeper.

The Added Cost

Eyelets are an additional component that must be purchased. While the cost per frame is minimal, it can add up when assembling hundreds of frames for a large apiary.

The Extra Labor

Installing eyelets is an extra step in the already time-consuming process of building frames. It requires a specialized tool (an eyelet punch) or careful work with a nail set to seat them properly without splitting the wood.

When Are They Unnecessary?

If you are using all-plastic frames or frames with plastic foundation that includes integrated vertical supports, you may not need to wire them at all. In these cases, eyelets are irrelevant. However, for any beekeeper using wooden frames with wax foundation, they are considered a best practice for long-term durability.

The Right Choice for Your Apiary

Ultimately, the decision to use eyelets depends on your goals for your equipment.

- If your primary focus is longevity and reliability: Use metal eyelets to ensure your frames withstand years of use without the wire loosening or damaging the wood.

- If your primary focus is minimizing initial cost and assembly time: You can skip eyelets, but accept that your frames will have a shorter functional lifespan.

Building your equipment to last is a cornerstone of sustainable beekeeping.

Summary Table:

| Aspect | Without Eyelets | With Eyelets |

|---|---|---|

| Wood Protection | Wire cuts into wood, causing damage | Metal sleeve prevents cutting action |

| Wire Tension | Tension slackens over time | Maintains consistent high tension |

| Frame Lifespan | Shorter lifespan due to wear | Significantly extended longevity |

| Best For | Short-term, low-cost setups | Commercial apiaries & sustainable beekeeping |

Build Frames That Last a Lifetime

Tired of replacing frames damaged by high-tension wire? HONESTBEE supplies durable beekeeping supplies and equipment, including frames pre-fitted with metal eyelets, to commercial apiaries and distributors. Our wholesale-focused operations ensure you get reliable, long-lasting equipment that protects your investment.

Contact HONESTBEE today to discuss your frame and equipment needs and ensure the longevity of your apiary!

Visual Guide

Related Products

- Heavy-Duty Stainless Steel Clip-On Frame Perch

- JZBZ Langstroth Queen Rearing Frame for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Heavy-Duty T-Style Frame Perch

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

People Also Ask

- How does the beehive frame perch improve hive inspections? Boost Efficiency & Protect Your Hive

- How many frames can a frame perch hold? Optimize Your Hive Inspections with the Right Tool

- What options are available for the frame perch? Choose Between 1-Piece or 2-Piece Designs

- What is the function of a frame perch? Enhance Your Hive Inspections and Ensure Colony Safety

- How does the frame perch ensure stability during use? Secure Your Hive Inspections with Physics-Driven Design