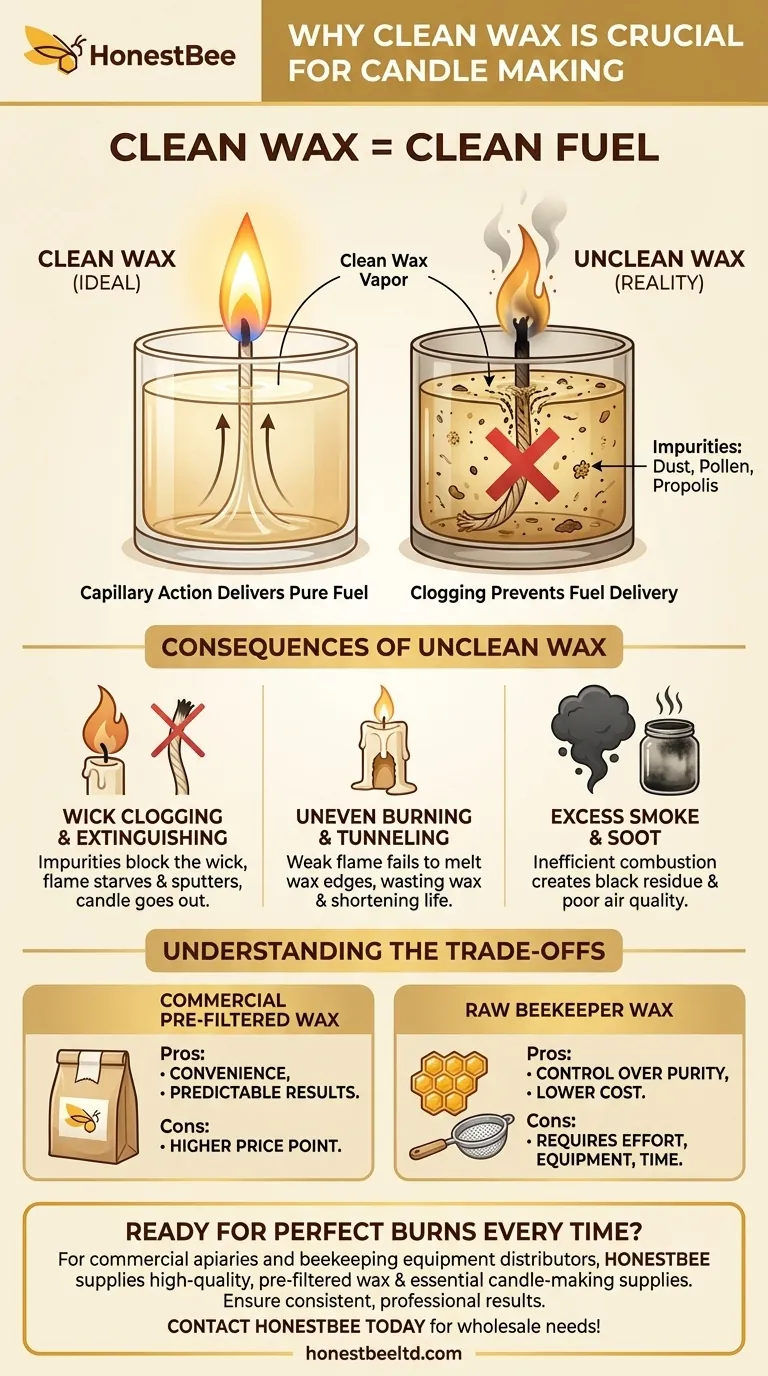

In short, you must use clean wax because any impurities will clog the candle's wick. This blockage prevents the wick from drawing fuel (molten wax) to the flame, resulting in a candle that burns unevenly, produces excess smoke, or extinguishes itself entirely. The purity of your wax is the single most important factor for a successful, clean-burning candle.

The performance of a candle hinges on one simple mechanical process: the wick's ability to draw clean, liquid fuel to the flame. Using unclean wax is like putting sludge in a car's fuel line—it inevitably leads to failure.

The Physics of a Candle Flame

The Wick as a Fuel Delivery System

A candle wick works through a process called capillary action. It acts like a straw, continuously drawing the pool of molten wax up to the flame against gravity.

This delivery system is the engine of your candle. Its efficiency determines the stability, size, and cleanliness of the flame.

Wax is the Fuel, Not the Wick

A common misconception is that the flame is burning the string wick itself. In reality, the heat of the flame vaporizes the liquid wax delivered by the wick, and it is this wax vapor that serves as the fuel for combustion.

A properly functioning candle is a self-sustaining system where the flame melts wax, and the wick delivers that wax back to the flame.

How Impurities Sabotage the System

Impurities in the wax—such as dust, pollen, propolis, or honey residue in raw beeswax—cannot be vaporized by the flame.

As the wick draws up the molten wax, these solid particles become lodged within the wick's woven fibers. This creates a physical blockage, or clog, that stops the flow of fuel.

The Consequences of Using Unclean Wax

Wick Clogging and Flame Extinguishing

The most immediate result of using dirty wax is wick clogging. The flame will begin to shrink, sputter, and struggle as its fuel supply is cut off. In many cases, the flame will extinguish itself completely.

Uneven Burning and Tunneling

A weak, starving flame does not generate enough heat to melt the wax all the way to the edge of the container. This causes the candle to burn a narrow hole down the center, a frustrating problem known as tunneling.

Tunneling wastes significant amounts of wax and dramatically shortens the functional life of your candle.

Excessive Smoke and Soot

When a flame is improperly fueled, combustion becomes inefficient. A starving flame will produce significantly more smoke and soot (unburnt carbon particles) as it struggles to burn.

This not only coats the candle container in black residue but also releases particulates into the air.

Understanding the Trade-offs

Convenience vs. Cost

Commercially prepared wax is almost always sold pre-filtered and ready to use. This offers maximum convenience and predictable results, but it comes at a higher price point.

Raw wax, sourced directly from a beekeeper, is often more affordable but is guaranteed to contain impurities.

Control vs. Effort

Cleaning raw wax yourself gives you absolute control over the purity of your final product. This aligns with the goal of creating a truly natural, non-toxic candle from scratch.

However, the process of cleaning and filtering wax requires time, dedicated equipment, and can be quite messy. It involves multiple cycles of melting and straining the wax through progressively finer filters to remove all debris.

Making the Right Choice for Your Goal

Choosing your wax depends entirely on your project's priorities.

- If your primary focus is convenience and reliable results for your first projects: Start with commercially prepared, pre-cleaned wax to eliminate a major variable.

- If your primary focus is controlling every ingredient or using raw, local materials: Commit to learning the wax rendering and filtering process before you begin making your candles.

Ultimately, understanding that clean wax is clean fuel is the foundational principle for mastering the art of candle making.

Summary Table:

| Issue | Cause | Consequence |

|---|---|---|

| Wick Clogging | Impurities (dust, pollen) block the wick's fibers. | Flame sputters or extinguishes. |

| Tunneling | Weak flame fails to melt wax to the container's edge. | Wasted wax, shorter candle life. |

| Excess Smoke/Soot | Inefficient combustion from a starved flame. | Black residue, poor air quality. |

Ready to ensure your candles burn perfectly every time?

For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies high-quality, pre-filtered wax and essential candle-making supplies through our wholesale operations. Using clean, reliable materials is the first step to a superior product. Let us help you achieve consistent, professional results.

Contact HONESTBEE today to discuss your wholesale supply needs!

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Rolling Wax Cutter with Ergonomic Handle

- Wide Adjustable Stainless Steel Honey Uncapping Fork with Scraper

- Professional Stainless Steel J-Hook Hive Tool

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the primary function of solar or steam wax melters in the initial processing of raw beeswax? Maximize Wax Purity

- What should be done if melted beeswax starts to solidify? Tips for Re-melting and Workflow Management

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- How do beekeepers typically harvest beeswax? Efficient Techniques for Collecting and Rendering High-Quality Wax

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency