The primary reason a commercial beekeeper prefers an electric beeswax melter is its capacity to process large volumes of wax quickly and reliably. For a commercial operation, honey extraction produces hundreds or even thousands of pounds of beeswax cappings, an amount that slower, weather-dependent methods simply cannot handle efficiently.

The decision to use an electric melter is not just about convenience; it is a strategic business choice. It provides the speed, control, and scale necessary to turn beeswax from a cumbersome byproduct into a profitable, streamlined revenue source.

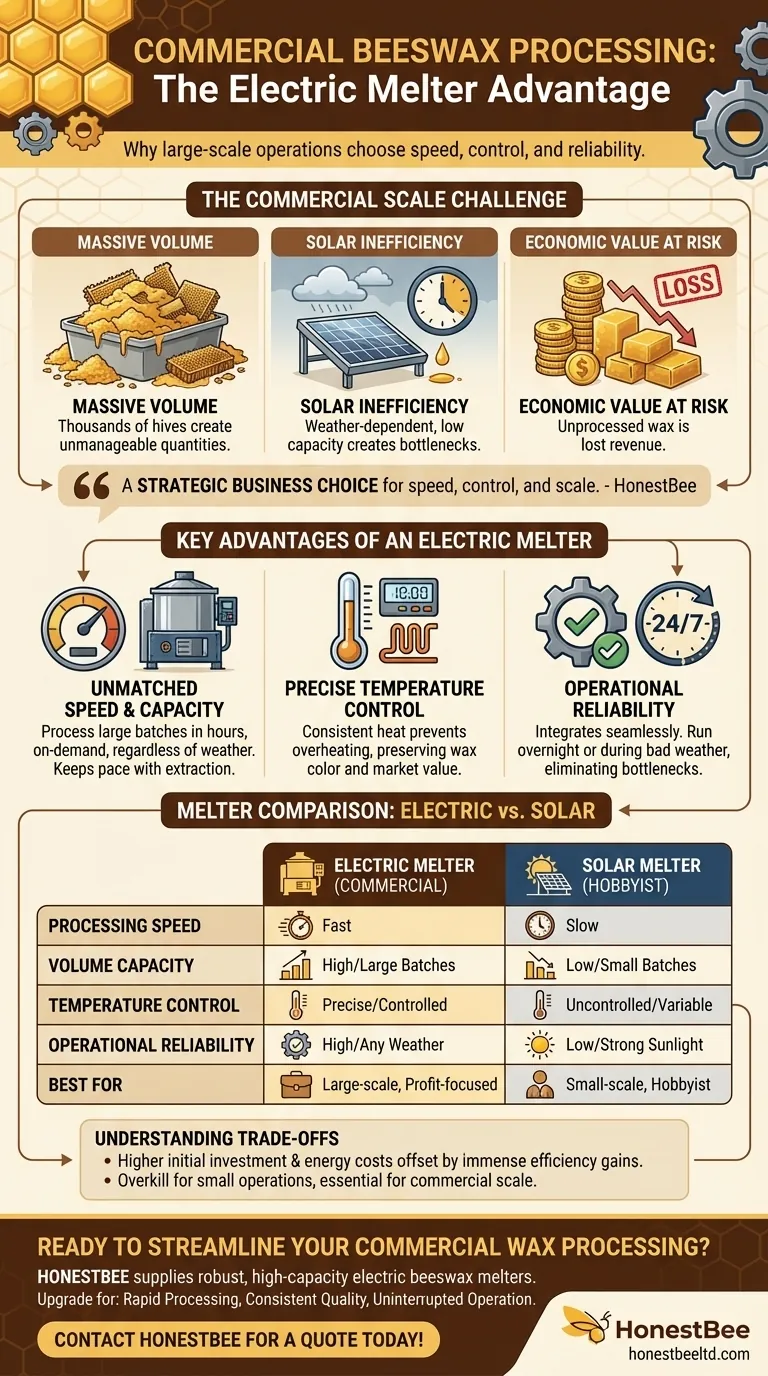

The Challenge of Commercial Scale

Commercial beekeeping operates on a timeline and volume that is orders of magnitude greater than hobbyist beekeeping. This fundamental difference dictates the choice of equipment for every task, including wax rendering.

The Sheer Volume of Wax

A commercial apiary with thousands of hives generates a massive quantity of beeswax cappings and old comb during honey extraction season.

Processing this volume is not a casual task but a major operational step. Any delay or bottleneck in wax rendering can slow down the entire honey house workflow.

The Inefficiency of Solar Power

Solar melters are an excellent, low-cost option for hobbyists. However, they rely on strong, direct sunlight and can only process a small amount of wax at a time.

For a commercial beekeeper, depending on the weather and a slow process is not a viable business model. It would create an unmanageable backlog of unprocessed wax.

The Economic Value of Beeswax

Beeswax is a valuable commodity used in cosmetics, candles, food production, and for creating new hive foundation.

Leaving this value unprocessed due to inefficient methods is a direct financial loss. Efficient processing snelheid allows the beekeeper to capture this revenue quickly.

Key Advantages of an Electric Melter

An electric melter is an industrial tool designed to meet the demands of a commercial workflow. It offers three core advantages: speed, control, and reliability.

Unmatched Speed and Capacity

An electric melter can render large batches of wax in a matter of hours, regardless of the time of day or weather conditions. This on-demand capability is essential for keeping pace with a commercial extraction line.

Precise Temperature Control

Unlike solar melters, electric units offer consistent and controllable heat. This prevents the wax from overheating, which can darken its color and reduce its quality and market value.

Operational Reliability

Electric melters integrate seamlessly into a professional workflow. They can be run overnight or during periods of bad weather, ensuring that wax processing never becomes the bottleneck that holds up other critical tasks.

Understanding the Trade-offs

While superior for commercial use, electric melters are not the right choice for every beekeeper. The decision involves clear trade-offs related to cost and scale.

Higher Initial Investment

A commercial-grade electric melter પાણી represents a significant upfront cost compared to a simple DIY or purchased solar melter. This investment is only justifiable at a certain scale of production.

Ongoing Energy Costs

Unlike the free energy provided by the sun, electric melters consume electricity, adding to the operational costs of the business. This cost, however, is typically offset by the immense gains in efficiency and product throughput.

Overkill for Small Operations

For a beekeeper with only a handful of hives, an electric melter is unnecessary. The small volume of wax produced can be easily and economically managed with a solar melter or other small-batch methods.

Making the Right Choice for Your Goal

Your choice of a wax melter should be directly aligned with the scale and goals of your beekeeping operation.

- If your primary focus is hobby beekeeping: A solar melter is an economical and environmentally friendly choice perfectly suited for processing wax from a few hives.

- If your primary focus is growing a sideline business: You may reach a point where solar becomes a bottleneck, and investing in a small electric melter will dramatically improve your workflow.

- If your primary focus is commercial production: An electric melter is an essential piece of equipment for efficiently managing large volumes and maximizing the profitability of your beeswax.

Ultimately, the right melter aligns your processing capacity with your production volume, turning a necessary task into a valuable opportunity.

Summary Table:

| Feature | Electric Melter (Commercial) | Solar Melter (Hobbyist) |

|---|---|---|

| Processing Speed | Fast (hours, on-demand) | Slow (days, weather-dependent) |

| Volume Capacity | High (large batches) | Low (small batches) |

| Temperature Control | Precise (prevents overheating) | Uncontrolled (varies with sun) |

| Operational Reliability | High (works day/night, any weather) | Low (requires strong sunlight) |

| Best For | Large-scale, profit-focused operations | Small-scale, hobbyist beekeeping |

Ready to Streamline Your Commercial Wax Processing?

For commercial apiaries and beekeeping equipment distributors, efficient wax rendering is key to maximizing profitability. HONESTBEE supplies robust, high-capacity electric beeswax melters designed for the demands of your large-scale operation.

Upgrade your honey house workflow with equipment that delivers:

- Rapid Processing: Handle large volumes of wax cappings without bottlenecks.

- Consistent Quality: Precise temperature control protects the value of your beeswax.

- Uninterrupted Operation: Render wax on your schedule, independent of weather.

Contact HONESTBEE today to discuss your needs and discover how our wholesale-focused solutions can enhance your efficiency and bottom line.

Get a Quote for Your Commercial Wax Melter Now!

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control