While technically possible, using a microwave is not the recommended method for melting wax due to a critical lack of temperature control. This imprecision introduces significant risks, including creating a fire hazard and damaging the quality of the wax, making the process unreliable for anything beyond small, occasional hobby projects.

The core issue is control. Microwaves heat wax unevenly and make it impossible to monitor temperature accurately, creating dangerous hotspots that can easily exceed the wax's flashpoint and cause it to ignite.

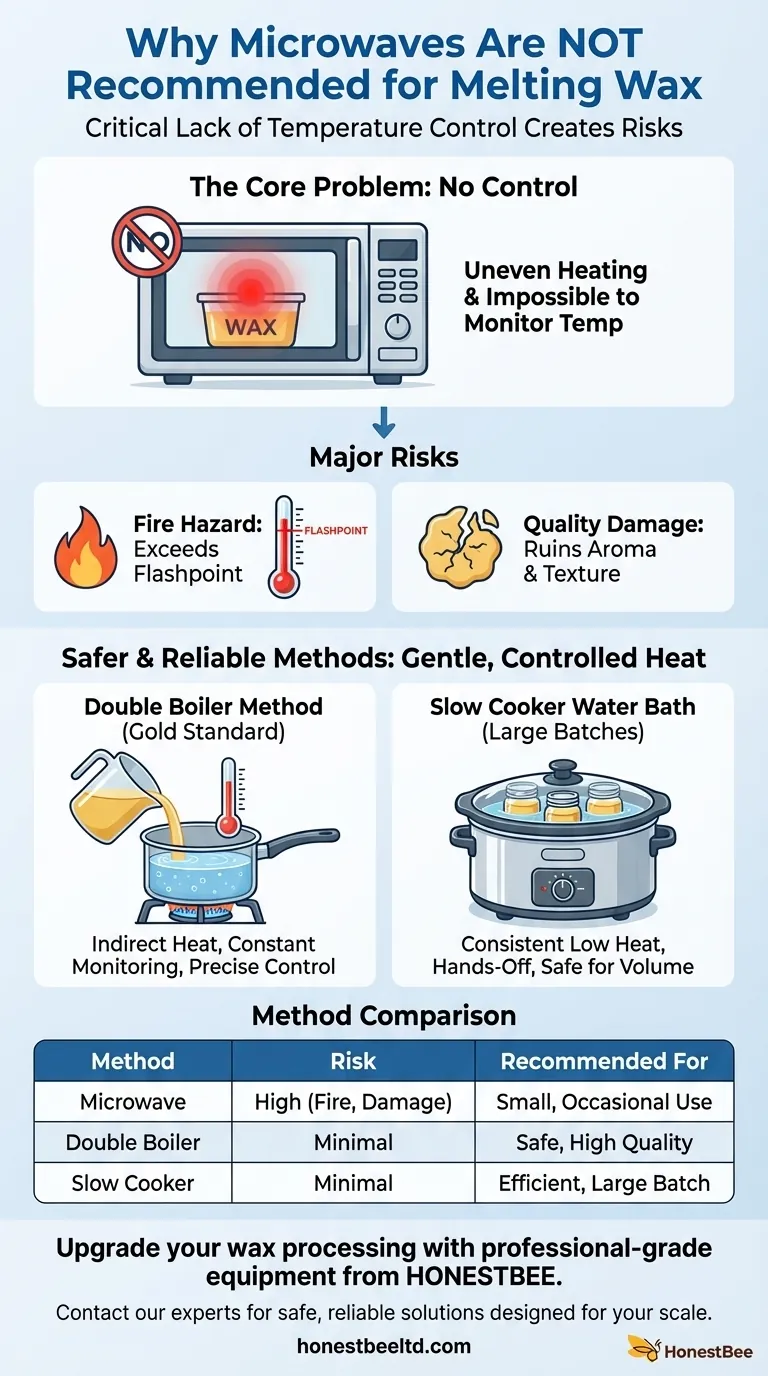

The Core Problem: A Lack of Control

To understand why microwaves are ill-suited for this task, you must first understand how they work and how wax behaves when heated. The two are fundamentally incompatible for achieving a safe, high-quality result.

Uneven Heating and Hotspots

Microwaves work by agitating water and fat molecules, but they do so unevenly. This process creates super-heated pockets within the wax while other areas can remain completely solid.

You cannot stir or equalize the temperature during the heating cycle, leading to a volatile and unpredictable state within the container.

The Inability to Monitor Temperature

Proper wax melting requires keeping the wax within a specific temperature range. This is typically done with a thermometer.

You cannot safely use a thermometer inside a running microwave. This forces you into a dangerous guessing game of heating, stopping, checking, and repeating, with no real-time data on how hot the wax is becoming.

Damaging the Wax Quality

Exceeding the ideal temperature doesn't just pose a safety risk; it ruins the wax itself.

For waxes like beeswax or other scented varieties, overheating can permanently destroy their natural aroma or added fragrance oils. This leaves you with a finished product, like a candle, that fails to perform as expected.

Understanding the Risks: More Than Just Melted Wax

The convenience of a microwave is tempting, but it is overshadowed by two significant dangers: the risk of fire and the certainty of a lower-quality outcome.

The Flashpoint and Fire Hazard

Every type of wax has a flashpoint—the lowest temperature at which its vapors can ignite when exposed to a flame or spark.

When wax is overheated in a microwave, it can easily surpass this flashpoint. The super-heated vapors can then auto-ignite or be ignited by a small spark, creating a serious and difficult-to-extinguish grease fire.

Ruined Materials and Wasted Effort

Even if you avoid a fire, the lack of control almost guarantees a subpar result. The time and money invested in quality wax, wicks, and fragrances are wasted if the wax is scorched during the melting process.

Safer and More Reliable Methods

Professional candle makers and serious hobbyists prioritize gentle, even heating. These methods provide the control that a microwave fundamentally lacks.

The Double Boiler Method

This is the gold-standard technique. A pouring pot containing the wax is placed inside a larger pot of simmering water.

This method ensures the wax never comes into direct contact with the heat source. It provides slow, even heating and allows for constant temperature monitoring with a thermometer, giving you complete control.

The Slow Cooker (Crock-Pot) Water Bath

For larger batches, a slow cooker offers a similar "set it and forget it" approach. Jars of wax are placed in a water bath inside the slow cooker.

The appliance's low, consistent heat melts the wax gently over a longer period, preventing scorching and eliminating the risk of fire.

Making the Right Choice for Your Goal

Your choice of method should be dictated by your priorities for safety, quality, and scale.

- If your primary focus is a quick, one-off experiment: Using a microwave is possible with extreme caution—use very short bursts (15-30 seconds), stir thoroughly between each interval, and never leave it unattended.

- If your primary focus is safety and a high-quality result: The double boiler method is the definitive choice for its precision, control, and reliability.

- If your primary focus is melting larger batches efficiently: A slow cooker water bath provides a safe and hands-off way to gently melt wax at scale.

Ultimately, prioritizing controlled, gentle heat is the key to melting wax safely and creating a product you can be proud of.

Summary Table:

| Method | Key Risk | Recommended For |

|---|---|---|

| Microwave | Uneven heating, fire hazard, quality damage | Small, occasional hobby use only |

| Double Boiler | Minimal risk with proper use | Safe, high-quality results |

| Slow Cooker Water Bath | Minimal risk with proper use | Efficient, large-batch melting |

Upgrade your wax processing with professional-grade equipment from HONESTBEE.

As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, we provide the reliable, safe melting solutions you need to protect your wax quality and your operation. Stop risking your valuable materials with unsafe methods.

Contact our experts today to discuss wholesale pricing on durable wax melters and supplies designed for your scale.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide