For large beekeeping operations, manual uncapping methods cease to be practical and become a critical bottleneck in the honey extraction workflow. Automation is not a luxury but a necessity driven by the need for speed, efficiency, and the ability to process a high volume of honey frames in a limited amount of time.

The decision to automate uncapping is less about the tool and more about the workflow. When the time spent manually uncapping frames exceeds the capacity of your extractor and stalls your entire honey house operation, automation becomes essential for growth.

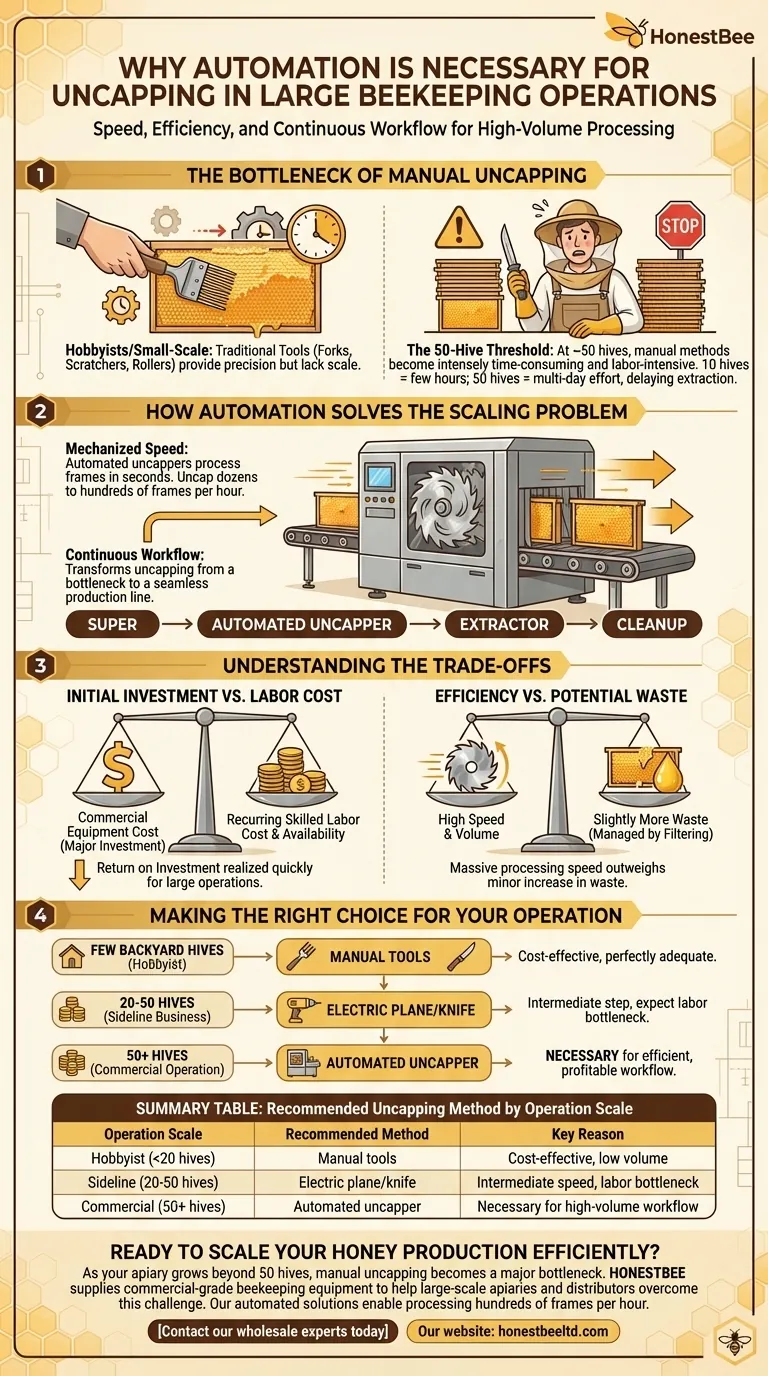

The Bottleneck of Manual Uncapping

For hobbyists or small-scale beekeepers, traditional uncapping tools are perfectly suitable. However, these methods do not scale effectively as an operation grows.

The Limits of Traditional Tools

Tools like an uncapping fork, scratcher, or roller are precise and give the beekeeper complete control. They are excellent for a handful of hives where time is not the primary constraint.

An electric hot knife or uncapping plane speeds up the process significantly compared to a cold knife or fork. Yet, even these require a skilled hand and are fundamentally a one-frame-at-a-time manual process.

The 50-Hive Threshold

The references identify a common tipping point around 50 beehives. At this scale, the sheer volume of frames to be uncapped makes manual methods intensely time-consuming and labor-intensive.

What might take a few hours for 10 hives can become a multi-day effort for 50, delaying the entire extraction and bottling process. This inefficiency represents a direct cost in labor and a potential loss of product quality if honey sits too long.

How Automation Solves the Scaling Problem

Automation directly addresses the speed and volume limitations of manual work. It transforms uncapping from the slowest step into a seamless part of a continuous production line.

Introducing Mechanized Speed

Automated uncappers, which use spinning blades or flails, can process a frame in seconds. The operator simply feeds frames into the machine, which quickly and uniformly removes the wax cappings.

This allows a beekeeper to uncap dozens or even hundreds of frames per hour, a rate that is impossible to achieve manually. The goal shifts from meticulously uncapping each frame to efficiently supplying the machine.

Creating a Continuous Workflow

With uncapping no longer a bottleneck, a large operation can achieve a continuous workflow. Frames move quickly from the super, through the uncapper, into the extractor, and back out for cleanup.

This principle extends to other parts of the process. For example, large operations also use honey presses to crush and process large batches of honeycomb, another form of mechanization designed to handle high volume without frequent stops.

Understanding the Trade-offs

Moving to automation is a significant decision with clear benefits but also important considerations.

Initial Investment vs. Labor Cost

The primary barrier to automation is the significant upfront cost of the equipment. A commercial-grade uncapper is a major investment compared to a $50 hot knife.

However, this cost must be weighed against the recurring expense and availability of skilled labor required to manually process honey at scale. For a large operation, the return on investment for automation is often realized quickly through labor savings and increased throughput.

Efficiency vs. Potential Waste

While modern automated uncappers are highly efficient, they can sometimes be more aggressive than a careful hand. This may lead to slightly deeper cuts into the comb or more wax mixed with the honey compared to a meticulous manual method.

However, the massive increase in processing speed almost always outweighs the minor increase in waste, which can be managed with effective filtering and separation systems downstream.

Making the Right Choice for Your Operation

Choosing your uncapping method depends entirely on the scale and goals of your beekeeping.

- If your primary focus is managing a few backyard hives: Stick with manual tools like an uncapping fork or a simple hot knife; they are cost-effective and perfectly adequate.

- If your primary focus is growing from a hobby to a sideline business (20-50 hives): An electric uncapping plane or hot knife is a good intermediate step, but be prepared to face a labor bottleneck.

- If your primary focus is running a commercial operation (50+ hives): Automation is necessary to maintain an efficient and profitable workflow; a mechanized uncapper is a required investment.

Ultimately, your equipment must serve your operational scale to ensure your honey harvest is a smooth and profitable process.

Summary Table:

| Operation Scale | Recommended Uncapping Method | Key Reason |

|---|---|---|

| Hobbyist / Small (<20 hives) | Manual tools (fork, hot knife) | Cost-effective, adequate for low volume |

| Sideline Business (20-50 hives) | Electric uncapping plane/knife | Intermediate speed, but labor becomes a bottleneck |

| Commercial (50+ hives) | Automated uncapper (blades/flails) | Necessary for high-volume, continuous workflow |

Ready to scale your honey production efficiently?

As your apiary grows beyond 50 hives, manual uncapping becomes a major bottleneck. HONESTBEE supplies commercial-grade beekeeping equipment to help large-scale apiaries and distributors overcome this challenge. Our automated uncapping solutions enable you to process hundreds of frames per hour, transforming your honey extraction workflow.

Contact our wholesale experts today to discuss how our equipment can help your commercial operation achieve greater efficiency and profitability.

Visual Guide

Related Products

- Lightweight Plastic Uncapping Roller with Tines

- Automatic Honey Frame Uncapper Machine for Beekeeping

- Professional Wide Head Honey Uncapping Fork for Beekeeping

- Stainless Steel Dual Blade Uncapping Plane

- Professional Multi-Function Uncapping Fork with Integrated Blade for Beekeeping

People Also Ask

- What are some tools that can be used to remove wax cappings from honeycomb? Choose the Right Tool for Your Harvest Scale

- What is the primary function of automatic uncapping equipment? Boost Your Honey Production Speed and Efficiency

- What is honey uncapping? The Essential First Step to Harvest Your Honey

- What are the advantages of using an automatic uncapping machine? Boost Efficiency & Preserve Your Honeycombs

- What is the recommended workflow for uncapping frames? Master the Batch-Processing Method for Efficiency

- How do beeswax cappings affect honey dripping efficiency? Optimize Your Processing Speed and Purity

- What is the function of uncapping in honey extraction? Unlock Your Harvest Efficiency

- What uncapping methods are suggested for beekeeping operations with more than 50 hives? Boost Efficiency with Automation