A Small Tragedy, Magnified

It’s a familiar and disheartening scene for any beekeeper. You open a hive to refill the frame feeder, expecting to see a thriving colony hard at work, only to find a layer of your bees lifeless in the syrup.

This isn't just bad luck. It’s not a sign of a weak colony.

It is a design failure. A small, seemingly insignificant detail in a piece of plastic equipment creates a death trap, and this small tragedy, magnified across thousands of commercial apiaries, represents a significant and entirely preventable loss.

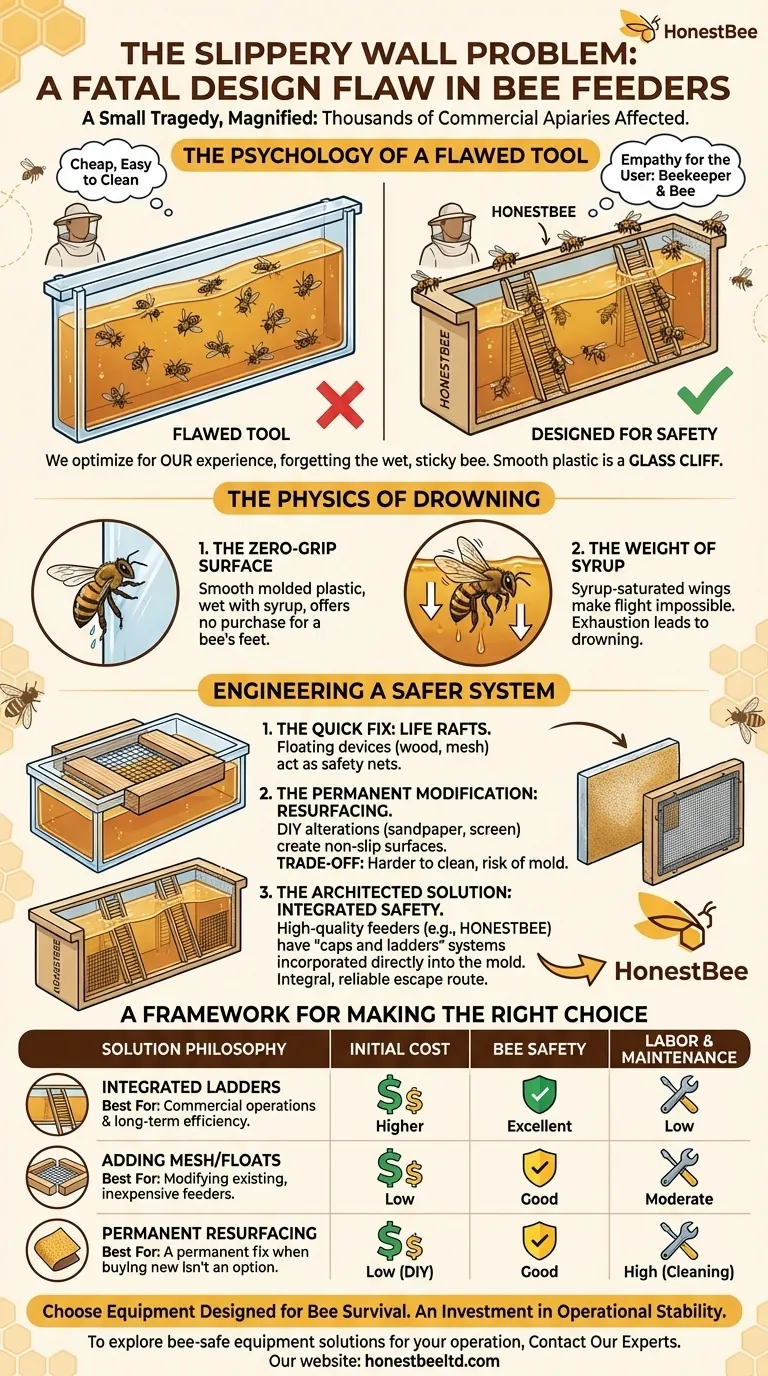

The Psychology of a Flawed Tool

Why are so many feeders designed this way? The answer lies in human psychology, not bee biology.

We see a smooth-walled plastic feeder and our minds register positive traits: it’s inexpensive, simple to manufacture, and easy to clean. We optimize for our own experience.

We fail to see the world from the perspective of a wet, sticky bee. We forget that for a creature weighing less than a tenth of a gram, a smooth plastic wall slick with viscous syrup is not a wall—it’s a glass cliff. This oversight is a cognitive shortcut, prioritizing immediate cost and convenience over the hidden, long-term cost of bee mortality.

The Physics of Drowning

To a bee, the frame feeder presents two fundamental physical challenges that combine to create a fatal environment.

1. The Zero-Grip Surface

A bee's feet are designed to grip textured surfaces. The molded plastic of many feeders is perfectly smooth. Once a bee's feet are wet with syrup, the surface tension and lack of texture make it impossible to gain purchase. Every attempt to climb out is futile.

2. The Weight of Syrup

Syrup is heavy and sticky. When a bee falls in, its wings are instantly saturated, rendering flight impossible. The struggle to climb the slick walls only drains its energy, and exhaustion leads quickly to drowning. It’s a quiet, slow-motion crisis happening inside the box.

Engineering a Safer System

The solution isn't complicated. It requires introducing a physical structure that provides a reliable escape route. This can be approached with three different philosophies, moving from a quick fix to a truly engineered solution.

The Quick Fix: Life Rafts

The most common modification is adding a floating device to the syrup. This acts as a life raft for any bee that falls in.

- Wooden floats or wine corks: Cheap and easy, but they can absorb syrup, become moldy, and get stuck to the sides as the level drops.

- #8 hardware cloth or plastic mesh: A far better option. Cut to size, it provides a durable, cleanable, and comprehensive safety net across the syrup's surface.

The Permanent Modification: Resurfacing

For a more permanent DIY solution, you can alter the feeder's interior to create a non-slip surface. This can involve roughing up the plastic with sandpaper or gluing in plastic window screen to create a permanent ladder.

The significant trade-off here is cleanliness. These textured surfaces trap syrup and debris, making them much harder to clean thoroughly and increasing the risk of fermentation or mold.

The Architected Solution: Integrated Safety

The most effective and reliable approach is to use equipment that was designed with bee safety as a core feature from the start.

High-quality frame feeders, like those supplied by HONESTBEE, incorporate a "caps and ladders" system directly into the mold. These are rough-textured internal grids that extend into the syrup reservoir. They aren't an afterthought; they are an integral part of the design. Bees can easily crawl down the ladders to feed and, crucially, climb back out without risk.

A Framework for Making the Right Choice

The initial cost of a feeder is obvious. The cost of replacing dead bees, the loss of colony productivity, and the labor spent managing suboptimal equipment are hidden. For a commercial operation, these hidden costs are what truly impact the bottom line.

| Solution Philosophy | Initial Cost | Bee Safety | Labor & Maintenance | Best For |

|---|---|---|---|---|

| Integrated Ladders | Higher | Excellent | Low | Commercial operations & long-term efficiency |

| Adding Mesh/Floats | Low | Good | Moderate | Modifying existing, inexpensive feeders |

| Permanent Resurfacing | Low (DIY) | Good | High (Cleaning) | A permanent fix when buying new isn't an option |

A well-designed tool shows empathy for its user. In beekeeping, that user is both the beekeeper and the bee. The elegance of a feeder with built-in ladders is that it solves the Slippery Wall Problem completely, safeguarding the colony's population and the beekeeper's investment.

For commercial apiaries, where efficiency and colony health are paramount, choosing equipment designed for bee survival isn't an expense—it's a critical investment in operational stability. To explore bee-safe equipment solutions designed for the demands of your operation, Contact Our Experts

Visual Guide

Related Products

- Rapid Bee Feeder White Plastic 2L Round Top Feeder for 8 or 10-Frame Bee Hives

- HONESTBEE Entrance Bee Feeder Professional Hive Nutrition Solution for Beekeeping

- HONESTBEE Round Hive Top Bee Feeder for Syrup

- HONESTBEE Entrance Bee Feeder Efficient Hive Front Liquid Feeding Solution for Beekeeping

- HONESTBEE Professional Entrance Bee Feeder Hive Nutrition Solution

Related Articles

- How Beekeepers Can Optimize Autumn Feeding for Stronger Winter Colonies

- The Benevolent Trap: Why Your Bee Feeder's Design is a Matter of Life and Death

- How to Feed Bees During Shortages: Prevent Starvation and Sustain Colonies

- Optimizing Winter Beehive Survival: A Guide to Top Feeders for Cold-Weather Beekeeping

- How to Optimize Bee Colony Health: Science-Backed Feeding Strategies for Sustainable Buildup